Oil-Free Guide Rails

Trusted & reliable oil-free

guide rails & plate supplier

Trusted handyman services

As a manufacturer, we produce different steel bushes dimensions. Extensive Know-How. Short Periods Of Delivery. Small Minimum Quantities. Cost-Effective Prices. Highlights: Brochures Available, Offering Cost-Effective Prices.

Oil-free Slide Plates Online Sourcing

Custom solutions for your engineering needs.

QUALITY ENGINEERED BEARINGS:

Self-lubricating bearing material very good wear and low friction performance over a wide range of loads, speeds…

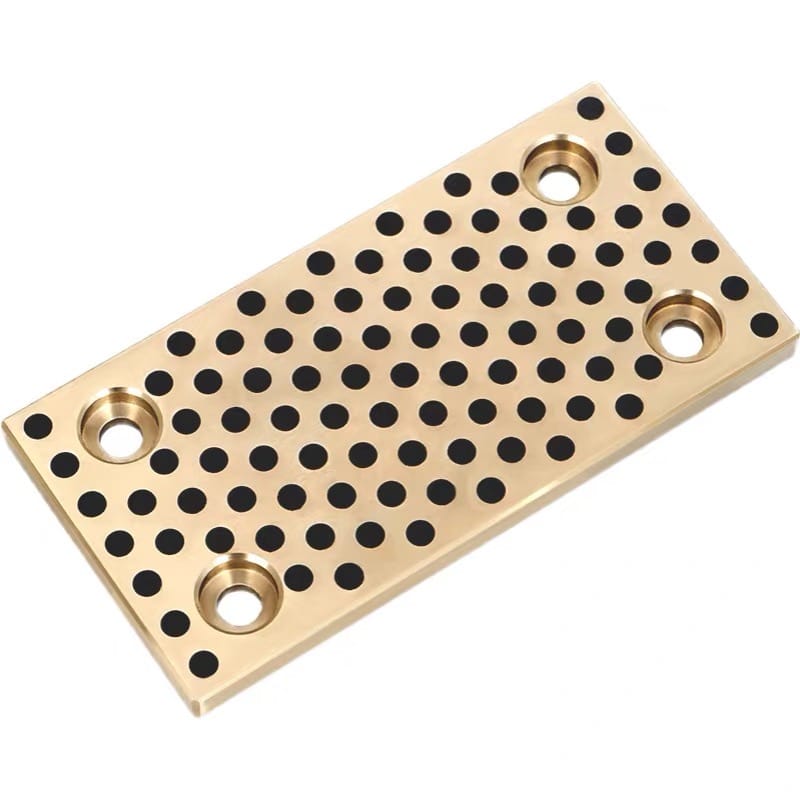

Switch to Oil-free Slide Plates – Metal Brass Friction Plate

Oil-free Slide Plates

Bronze Wear Strips – Holes and Graphite, Choose from our selection of bronze strips in a wide range of type and sizes.

Oil Free Parts Selection

Oil Free Copper Alloy Plate

Oil Free Guide Rails

L-Gibs/Lubrication-Free Copper Alloy

High performance at high load and low speed movement positions. with embedded solid lubricant in high-tensile brass. High tensile brass based / solid lubricant embedded. Wear-resistant bronze- for the toughest demands – bronzelube.com. Wear plate Manufacturer – Meet wear resistance needs

Oil Free Parts Selection

Special Solid Lubricant Embedded

Oil Free Plate Material: Bronze + Graphite

Wear Plate/Lubrication-Free Copper Alloy

Wear plate products with embedded solid lubricant in high-tensile brass.

Wear plate – Professional supplier. Our products are diverse, complete in specifications, and have low prices.

Oilless Wear Plates, Bronze Wear Plate – Select, configure, order. We delivers punctually and offers fair prices.

Oil Free Guide Rails | Online shop – Select, configure, order

Oil Free Guide Rails – Select, configure, order. we delivers punctually and offers fair prices. Oilless bronze wear plate & guide rails products are available in our online shop. Additionally, we offers a variety of CAD data for free download.

Choose your Application

Bronze Oilless Bearings for off-highway equipment. No Need for Complex Greasing System.

Finishing Parts Main Base Alloy

| Performance. & Chemical Compositions |

CuZn25Al6FeMn3 High Brass |

CuZn25Al6FeMn3 Special Brass |

CuSn5Pb5Zn5 Tin Bronze |

CuAl10Ni aluminium bronze |

CuSn12 Tin bronze |

Cast Iron HT250 EB00 |

| Cu% | 65 | 65 | 85 | 80 | 88 | |

| Sn% | 5 | 12 | ||||

| Pb% | 5 | |||||

| Zn% | 25 | 25 | 5 | |||

| Ni% | 5 | |||||

| Al% | 6 | 6 | 10 | |||

| Fe% | 5 | |||||

| Mn% | 4 | 4 | ||||

| Dengity g/cm 3 |

8.0 | 8.0 | 8.8 | 8.3 | 8.8 | 7.3 |

| Hardness | >210 | >180 | >70 | >150 | >80 | >160 |

| Tensile Strength | >750 | >550 | >200 | >500 | >360 | >250 |

| Elongation | >12 | >12 | 15 | >10 | >8 | |

| Coeicient of linear expansion |

1.9·10 -5 /℃ | 1.9·10 -5 /℃ | 1.8·10 -5 /℃ | 1.6·10 -5 /℃ | 1.8·10 -5 /℃ | 1.0·10 -5 /℃ |

| Limit Temp. | 300~400 | 300~400 | 400 | 400 | 400 | 400 |

| Max. Load N/mm 2 | 100 | 80 | 60 | 50 | 70 | 10 |

| Max. Speed m/min | 15 | 15 | 10 | 20 | 10 | 15 |

| Max. PV N/mm2·m/min | 200 | 200 | 200 | 200 | 200 | 40 |

| 400N/mm2 | <0.01 | <0.01 | <0.05 | <0.04 | <0.05 | <0.015 |

Friction of coe. Oil 0.03; Dry 0.16

Custom Size Options, machining bronze bushings and a supplier of solid bronze oilless bushes and plate delivered on time and on budget.

Oilless Bushing Alloy International Code

| Chinese Code GB1776-87 |

International counterparts | Applications | |||

| International ISO 1338 |

Japan Jis |

(USA) ASTM (UNS) |

German DIN |

||

| CuZn25AI6FeMn3 | CuZn25AI6FeMn3 | H5102 CAC304 |

B30-92 C86300 |

DIN1709 G-CuZn25A/2.0598 |

High-load, low speed, general use |

| CuZn25AI6FeMn3 | CuZn25AI6FeMn3 | H3102 CAC304 |

B30-92 C86300 |

DIN1709 G-CuZn25A/2.0598 |

Super high load, low-speed, high duty |

| CuAI10Fe3 | CuAI10Fe3 | H5114 CAC703 |

B30-92 95800 |

DIN1714 GB-CuAI10NI/2.1096 |

Medium load, medium-speed, general use |

| CuSn5Pb5Zn5 | QSn5-5-5 | H5111 CAC406 |

B30-92 C83600 |

DIN1705 G-Cu5n5ZnPb/2.1096 |

Medium load, medium-speed |

| DB5675-85 HT250 |

Fe250 | ASTM class40 |

low-load, low-speed | ||

Solid Lubricant

| Solid Lubricant | Features | Typical application |

| SSL1(PTFE etc + Add) | Excellent resistance against chemical attacks and low friction. Temp limit 400℃ |

Suite for general machines and under atmosphere |

| SL2(PTFE etc + Add2) | Lowest in friction and good of water lubrication,Temp.limit 300℃ |

Ship, hydraulic turbine, gas turbine etc. |

Call us

24/7 emergency callout