rg7 bronze equivalent

C93200 Alloy, C932 Leaded Tin Bronze Bushings, Rg7 Bushing Bronze Equivalent!

Explore the Various Types of Cast Bronze Bushing & Bearings Available from bronzelube.com. C93200(SAE660 RG7)Bushing, Alloy C93200, also termed C932, material bronze bearing. Oil Grooves in Cast Bronze Bearings. Has a groove to retain the lubricant. The lead content in high Leaded Tin Bronze alloys is between 7.00% & 15.00%.

due to its excellent wear resistance, good strength, and machinability. It is often used in applications such as automotive, heavy machinery, and industrial equipment. RG7 bronze, also known as continuous cast manganese bronze, shares many similar properties with C93200, making it a suitable equivalent for certain applications.

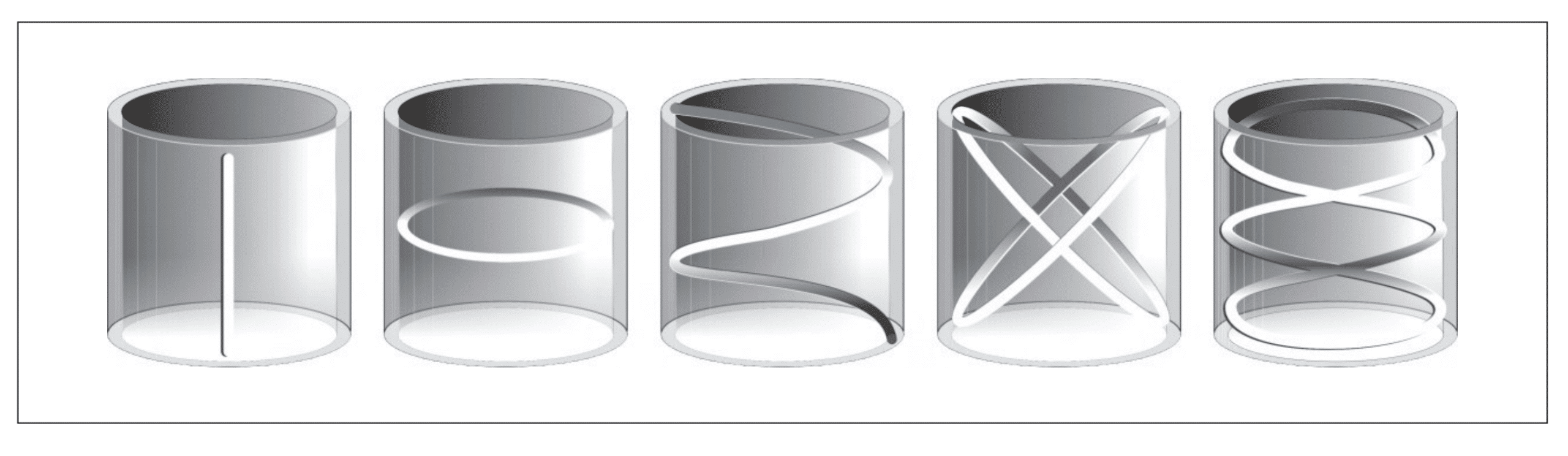

Bushing Oil Groove Design

Available

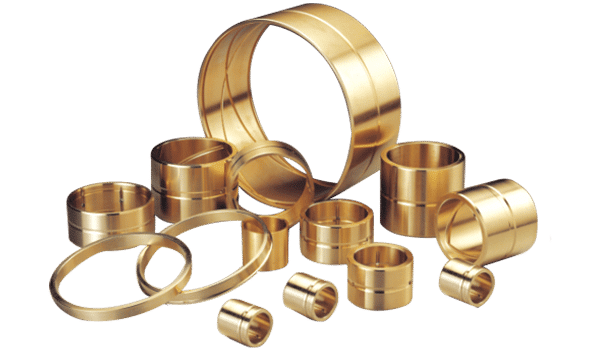

Cast Bronze Bearing

C93200(SAE660 RG7)Bronze Bearings

- Cylindrical bushes

- Thrust washers

- Flange bushes

- Non-standard parts as design

- Cast bronze bushing supplied by customer ordering, the

- tolerance is according to bushings standard dimension.

Comparison of Different Oil Groove Types for Cast Bronze Bearings

Oilless bronze bearing bush self-lubricating with …

| Oil Groove Type | Description | Advantages | Disadvantages | Best Applications |

| Straight Groove | Simple, straight-line grooves running parallel to the bearing surface. | Easy to manufacture; good oil distribution; effective for moderate loads and speeds. | Not as effective at high loads and speeds; may require additional grooves for optimal lubrication. | General-purpose bearings, moderate loads, and speeds. |

| Circular Groove | Continuous, concentric circular grooves on the bearing surface. | Excellent oil distribution; allows for uniform oil film development; effective at high speeds. | More difficult to manufacture; may require more frequent lubrication. | High-speed applications, rotating shafts, and high RPM equipment. |

| Double Figure-Eight Groove | Two interlocking figure-eight-shaped grooves on the bearing surface. | Efficient oil distribution; enhanced load-carrying capacity; suitable for oscillating and reciprocating motion. | Complex manufacturing process; may require additional grooves for optimal lubrication. | Heavy-duty applications, oscillating and reciprocating motion, high loads. |

| Axial Groove | A series of grooves running axially along the length of the bearing. | Efficient oil distribution under high loads; suitable for both rotating and reciprocating motion. | May require more frequent lubrication; not ideal for high-speed applications. | Heavy loads, linear and oscillating motion, vertical shafts. |

| Spiral Groove | A single, continuous spiral groove around the bearing surface. | Excellent oil distribution; effective at high speeds; helps prevent oil leakage. | More complex manufacturing process; may require more frequent lubrication. | High-speed applications, rotating shafts, and high RPM equipment, where oil leakage is a concern. |

The chart provides a comparison of different oil groove types for cast bronze bearings. The appropriate groove type should be selected based on factors such as bearing load, speed, and operating conditions.

Bronze Bushing Oil Groove Available Standard Metric Size Table

Below is a table of standard metric sizes for bronze bushings with oil grooves. These are commonly used in various applications, such as automotive, construction, and manufacturing equipment. The sizes listed are readily available, but custom sizes can also be produced depending on the specific requirements. The dimensions are in millimeters (mm).

Please note that this is a general guide, and you should always consult the manufacturer for specific product dimensions and tolerances.

| ID (Inner Diameter) | OD (Outer Diameter) | Length | Oil Groove Width | Oil Groove Depth |

|---|---|---|---|---|

| 10 | 12 | 15 | 2 | 1.5 |

| 12 | 14 | 20 | 2 | 1.5 |

| 15 | 17 | 20 | 2.5 | 1.5 |

| 18 | 20 | 25 | 2.5 | 1.5 |

| 20 | 23 | 25 | 3 | 2 |

| 25 | 28 | 30 | 3 | 2 |

| 30 | 34 | 35 | 3 | 2 |

| 35 | 39 | 40 | 4 | 2.5 |

| 40 | 44 | 45 | 4 | 2.5 |

| 45 | 50 | 50 | 5 | 3 |

| 50 | 55 | 60 | 5 | 3 |

| 55 | 60 | 70 | 6 | 3.5 |

| 60 | 65 | 75 | 6 | 3.5 |

| 65 | 70 | 80 | 6 | 3.5 |

| 70 | 75 | 85 | 7 | 4 |

| 75 | 80 | 90 | 7 | 4 |

| 80 | 85 | 95 | 8 | 4.5 |

| 85 | 90 | 100 | 8 | 4.5 |

| 90 | 95 | 110 | 9 | 5 |

| 95 | 100 | 120 | 9 | 5 |

| 100 | 105 | 130 | 10 | 5.5 |

Remember that this table is for general guidance only. It is important to verify the specific dimensions and tolerances with the manufacturer or supplier for your particular application.

Cast Bronze Bushing Oil Groove Available Standard Inch Size Table

Below is a table of standard inch sizes for cast bronze bushings with oil grooves. These are commonly used in various applications, such as automotive, construction, and manufacturing equipment. The sizes listed are readily available, but custom sizes can also be produced depending on the specific requirements. The dimensions are in inches.

Please note that this is a general guide, and you should always consult the manufacturer for specific product dimensions and tolerances.

| ID (Inner Diameter) | OD (Outer Diameter) | Length | Oil Groove Width | Oil Groove Depth |

|---|---|---|---|---|

| 1/2 | 5/8 | 3/4 | 1/8 | 1/16 |

| 5/8 | 3/4 | 1 | 1/8 | 1/16 |

| 3/4 | 7/8 | 1 | 1/8 | 1/16 |

| 7/8 | 1 | 1 1/4 | 3/16 | 3/32 |

| 1 | 1 1/8 | 1 1/2 | 3/16 | 3/32 |

| 1 1/4 | 1 3/8 | 1 3/4 | 3/16 | 3/32 |

| 1 1/2 | 1 5/8 | 2 | 1/4 | 1/8 |

| 1 3/4 | 1 7/8 | 2 1/4 | 1/4 | 1/8 |

| 2 | 2 1/8 | 2 1/2 | 1/4 | 1/8 |

| 2 1/4 | 2 3/8 | 2 3/4 | 5/16 | 5/32 |

| 2 1/2 | 2 5/8 | 3 | 5/16 | 5/32 |

| 2 3/4 | 2 7/8 | 3 1/4 | 5/16 | 5/32 |

| 3 | 3 1/8 | 3 1/2 | 3/8 | 3/16 |

| 3 1/4 | 3 3/8 | 3 3/4 | 3/8 | 3/16 |

| 3 1/2 | 3 5/8 | 4 | 3/8 | 3/16 |

Remember that this table is for general guidance only. It is important to verify the specific dimensions and tolerances with the manufacturer or supplier for your particular application.

Manufacturer of bronze and self lubricating bronze parts

(CC493K) Material Self lubricating bronze bearings.Grease Groove Bronze Bushings,Custom Made Service:Lubrication Oil Grooves Cutting.Specialists In Cutting Lubrication Grooves: Axial,Circumferential,Helical,Oval,Double oval,Figure of eight,One and a half figure of eight,Double figure of eight,Duplex figure of eight.

Specials machined to customer drawings:

- Oil and grease grooves

- Single Loop

- Figure Eight

- One Straight & One Circular

- Double Loop

- Double Figure Eight

- R.H. & L.H. Spiral

- Straight Groove

- Circular Groove

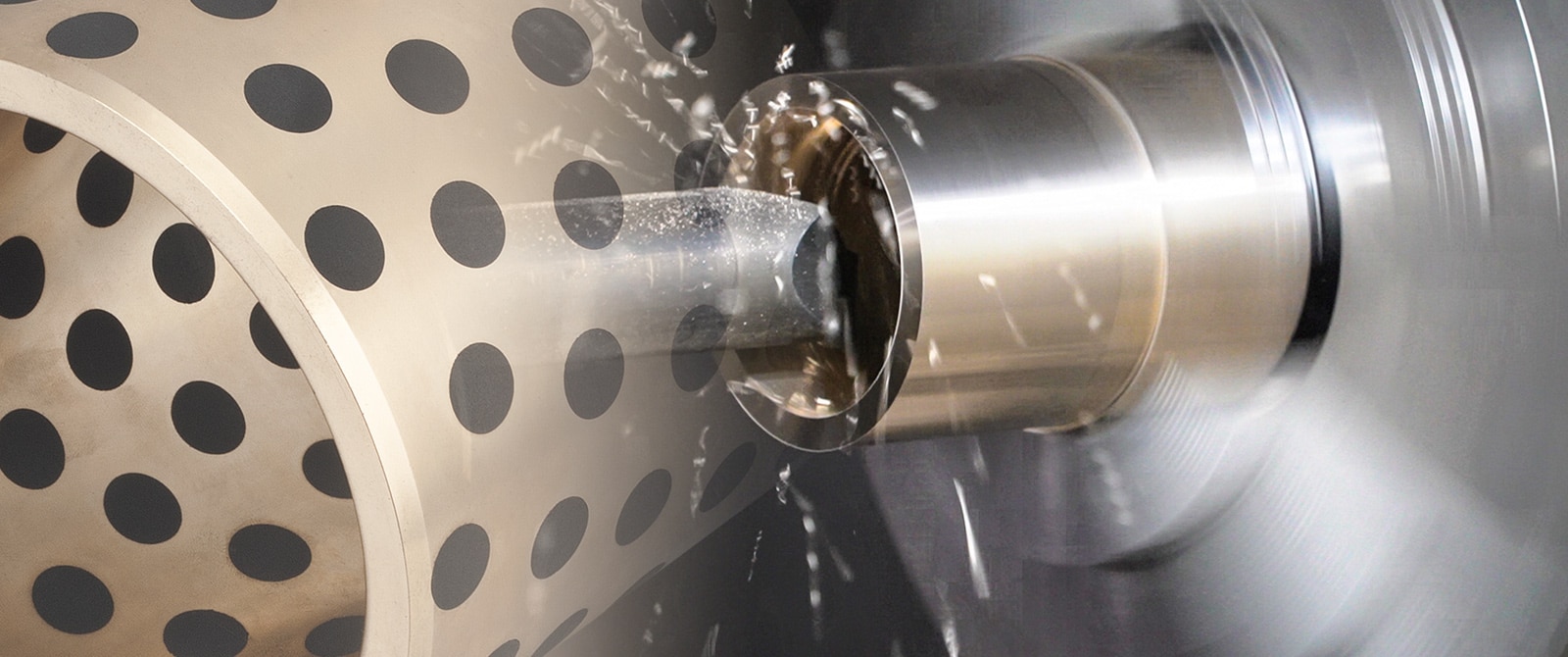

Discovery our range of high quality service parts,We manufacturer Tin Bronze bushing, Lead Bronze bearing, Aluminium Bronze bushes with graphite and High Tensile Brass parts. Other customization bronze alloy bushings which have not previously been mentioned can be manufactured available according customer’ designs or drawings.

Turned bronze bearings with lubrication grooves.

Characteristics

- Suitable for high loads

- Multiple areas of us (universal bearing)

- Long life

- Wide temperature range

| Technical Data | |

| Material: | Rg7/CC493K (red metal) groove bushings |

| Sliding layer (thickness): | Homogeneous |

| Tensile strength Rm: | 290N/mm² |

| Yield strength Rp 0.2: | 125N/mm² |

| Elongation in % A10: | 13-23% |

| Hardness: | 70-80HB |

| Friction coeff: | |

| Thermal conductivity: | 70W/m·K |

| Temperature range: | -100°C/225°C |

| Max. load static: | 90N/mm² |

| Max. load, dynamic: | 25N/mm² |

| Max. sliding speed (w.lubr.): | 3 m/s |

| Pv-value, Mpa x m/s, kont / int: | 2 |

| Recommended shaft hardness: | >165 HB |

| Rec. shaft surface roughness (Ra) | 1.6 |

| Recommended tolerance: | e7 |

| House: | H7 |

SHAPES & FORMS

- Cylindrical bushings

- flange bushings

- Plates

- Washers

- Other Custom Bearings Parts

Note:Grooves can be closed or open on one or both sides.There are different shapes and geometries of grooves which should be used according to the type of graphite bronze bearings.

RANGE OF APPLICATION

Forest machinery, pump housing parts, cylinder bearings, shipping & container industry etc.

SPECIAL MANUFACTURING

* For higher requirements – e.g. higher temperature ranges – different materials are available in this category.Special dimensions are available on request

Are you interested in our products?

Get a Quote Today!

Custom & Special Grooving Patterns Bronze Bushings:

Bronze bushings are crucial components in various applications, including automotive, aerospace, and heavy machinery. They provide low-friction movement and high load capacity, ensuring smooth and efficient operation. One way to enhance the performance of these bushings is through custom and special grooving patterns. These patterns can improve lubrication, heat dissipation, and debris management, leading to longer service life and reduced maintenance requirements.

-

Straight Grooves Straight grooves are the most common and straightforward grooving pattern for bronze bushings. They run parallel to the bushing’s axis, providing a continuous path for lubrication. This pattern is suitable for both rotating and oscillating applications, offering a good balance between performance and simplicity.

-

Spiral Grooves Spiral grooves wind around the bushing in a helical pattern. This design helps distribute lubrication evenly across the bushing’s surface and can also aid in moving debris away from critical contact areas. Spiral grooves are particularly effective in high-speed rotating applications where proper lubrication is crucial for optimal performance and reduced wear.

-

Circular Grooves Circular grooves, also known as radial or annular grooves, are concentric circles that run perpendicular to the bushing’s axis. This pattern is ideal for oscillating applications and evenly distributes lubricant around the bushing’s circumference. Circular grooves also help retain lubricant in place, making them a great choice for applications with intermittent or irregular movement.

-

Figure-8 Grooves Figure-8 grooves consist of two interconnected circular grooves forming a figure-8 pattern. This design combines the advantages of both straight and circular grooves, offering efficient lubrication distribution and effective debris management. Figure-8 grooves are well-suited for applications with both oscillating and rotating movements.

-

Diamond Grooves Diamond grooves consist of a series of diamond-shaped patterns on the bushing’s surface. This design provides excellent lubrication distribution while also facilitating debris removal. Diamond grooves can be customized to meet specific application requirements, making them a versatile option for a wide range of industries.

-

Custom Grooves For unique applications with specific requirements, custom grooving patterns can be developed. These may include a combination of the patterns mentioned above or entirely new designs tailored to the particular needs of the application. Custom grooves offer the flexibility to optimize bushing performance and ensure maximum efficiency and service life.

In conclusion, custom and special grooving patterns for bronze bushings can significantly improve the performance and lifespan of these critical components. By selecting the appropriate pattern based on the application’s requirements, you can optimize lubrication, heat dissipation, and debris management, leading to enhanced efficiency and reduced maintenance costs.

We offers to the international market excellent solutions in rolled products made of bronze and copper alloys

C93200 Alloy, C932 Leaded Tin Bronze RG7 Bushings Material:

| Cu | Sn | Pb | Zn | Fe | Ni | Sb | P | S | Al | Mn | Si | |

| 81.00-85.00 | 6.30-7.50 | 6.00-8.00 | 2.00-4.00 | 0.2 | 1.00† | 0.35 | 1.5 | 0.08 | 0.005 | N/A | 0.005 |

Oil Grooves for Bronze Bushings, C93200 bronze bearings & bushing, Rg7 bronze equivalent.

Custom and Special Grooving Patterns for Rg7 Bronze Bearing

RG7 bronze, also known as continuous cast manganese bronze, is a high-strength material with excellent wear resistance, making it an ideal choice for bearings in various industries. Custom and special grooving patterns can be applied to RG7 bronze bearings to enhance their performance, optimize lubrication, and improve heat dissipation and debris management. Here are some popular grooving patterns for RG7 bronze bearings:

-

Straight Grooves Straight grooves run parallel to the bearing’s axis, providing a continuous path for lubrication. This pattern is suitable for both rotating and oscillating applications, offering a good balance between performance and simplicity. Straight grooves are a popular choice for RG7 bronze bearings due to their ease of manufacturing and effectiveness.

-

Spiral Grooves Spiral grooves wind around the bearing in a helical pattern, ensuring even lubrication distribution across the bearing’s surface. This design also helps move debris away from critical contact areas, which is particularly beneficial in high-speed rotating applications. Spiral grooves can further enhance the wear resistance and longevity of RG7 bronze bearings.

-

Circular Grooves Circular grooves, also known as radial or annular grooves, consist of concentric circles running perpendicular to the bearing’s axis. This pattern is ideal for oscillating applications, as it evenly distributes lubricant around the bearing’s circumference. Circular grooves help retain lubricant in place, making them suitable for applications with intermittent or irregular movement.

-

Figure-8 Grooves Figure-8 grooves are formed by connecting two circular grooves, creating a figure-8 pattern. This design combines the advantages of both straight and circular grooves, offering efficient lubrication distribution and effective debris management. Figure-8 grooves are well-suited for applications that involve both oscillating and rotating movements, making them a versatile choice for RG7 bronze bearings.

-

Diamond Grooves Diamond grooves consist of a series of diamond-shaped patterns on the bearing’s surface. This design provides excellent lubrication distribution while also facilitating debris removal. Diamond grooves can be customized to meet specific application requirements, making them a versatile option for a wide range of industries using RG7 bronze bearings.

-

Custom Grooves For unique applications with specific requirements, custom grooving patterns can be developed. These may include a combination of the patterns mentioned above or entirely new designs tailored to the particular needs of the application. Custom grooves offer the flexibility to optimize the performance of RG7 bronze bearings and ensure maximum efficiency and service life.

In conclusion, custom and special grooving patterns for RG7 bronze bearings can significantly improve the performance and lifespan of these critical components. By selecting the appropriate pattern based on the application’s requirements, you can optimize lubrication, heat dissipation, and debris management, leading to enhanced efficiency and reduced maintenance costs.

Rg7 Bronze Mechanical Capacity High Quality Cast Bronze Bearing

| Tensile Strength (min) | Yield Strength (at .5% extention under load min) | Elongation (in 2in. or 50mm min, %) | Brinell Hardness (min) | Remarks | ||

| Ksi | MPa | Ksi | MPa | |||

| 35 | 241 | 20 | 138 | 10 | 65 | |

RG7 bronze, also known as continuous cast manganese bronze, is a high-strength material with excellent wear resistance. It is commonly used for bearings in various industries due to its impressive mechanical properties. Below is a chart that provides more details about the RG7 bronze bearing material:

| Property | Value / Description |

|---|---|

| Material Type | Continuous cast manganese bronze |

| Composition | Cu: 60-65%, Sn: 5-7%, Pb: 5-7%, Zn: 20-25%, Mn: 0.5-2% |

| Color | Yellowish-bronze |

| Density | 8.5-8.8 g/cm³ |

| Tensile Strength | 280-350 MPa |

| Yield Strength | 120-190 MPa |

| Elongation | 8-15% |

| Hardness (Brinell) | 70-130 HB |

| Coefficient of Friction (unlubricated) | 0.15-0.25 |

| Coefficient of Friction (lubricated) | 0.05-0.10 |

| Thermal Conductivity | 50-60 W/m·K |

| Melting Point | 950-1000°C |

| Corrosion Resistance | Good resistance to seawater, mild acids, and alkaline environments |

| Machinability | Good |

| Applications | Bearings, bushings, gears, worm wheels, heavy-duty machinery |

The chart above provides a comprehensive overview of the properties and characteristics of RG7 bronze bearings. By understanding these details, engineers and designers can make informed decisions about whether RG7 bronze is suitable for their specific applications.

C93200 Leaded Tin Bronze Bushings:

- Composition: C93200 is composed of Cu: 81-85%, Sn: 6.3-7.5%, Pb: 6-8%, Zn: 2-4%, and other elements in smaller quantities.

- Color: Yellowish-brown

- Density: 8.8-9.0 g/cm³

- Tensile Strength: 221-310 MPa

- Yield Strength: 103-179 MPa

- Elongation: 10-15%

- Hardness (Brinell): 65-90 HB

- Coefficient of Friction (unlubricated): 0.15-0.25

- Coefficient of Friction (lubricated): 0.05-0.10

- Thermal Conductivity: 60-70 W/m·K

- Melting Point: 900-950°C

- Corrosion Resistance: Good resistance to seawater, mild acids, and alkaline environments

- Machinability: Good

- Applications: Bearings, bushings, gears, worm wheels, heavy-duty machinery

RG7 Bushing Bronze Equivalent:

- Composition: RG7 is composed of Cu: 60-65%, Sn: 5-7%, Pb: 5-7%, Zn: 20-25%, Mn: 0.5-2%

- Color: Yellowish-bronze

- Density: 8.5-8.8 g/cm³

- Tensile Strength: 280-350 MPa

- Yield Strength: 120-190 MPa

- Elongation: 8-15%

- Hardness (Brinell): 70-130 HB

- Coefficient of Friction (unlubricated): 0.15-0.25

- Coefficient of Friction (lubricated): 0.05-0.10

- Thermal Conductivity: 50-60 W/m·K

- Melting Point: 950-1000°C

- Corrosion Resistance: Good resistance to seawater, mild acids, and alkaline environments

- Machinability: Good

- Applications: Bearings, bushings, gears, worm wheels, heavy-duty machinery

While the exact compositions and properties of C93200 and RG7 bronze differ slightly, they share many similarities, making them suitable alternatives for specific applications. Both materials offer good wear resistance, strength, machinability, and corrosion resistance, making them ideal choices for bushings and bearings used in various industries.

Cast Bronze Bearing

C93200(SAE660 RG7)Bronze Bushing & Flange Size.

We stand behind the quality of our standard bearings, sliding parts products. Oil & Grease Groove Bronze Bushings / Plugged with graphite C93200 (SAE 660) bronze bearings. Gunmetal, Red Bronze etc. Rg7 is the most common bronze alloy worldwide. The material properties makes this alloy well suited for bearings, valves, slide plates and similar bushing. Pressure-tight with good dry running properties and easy to machine simply makes this an excellent all around bronze alloy.

Top Quality Rg7 bronze equivalent

The promise of rg7 bronze bearings high quality, meet your requirement. Suitable for impact loads and vibrations at low speeds;

Grease-lubricated bearings rg7 bronze equivalent

High temperature self-lubricating bearings and bronze bushing.

Bronze Bearing Sourcing Online, Proven Integrity, Delivering Value.

Supplier of continuous cast copper alloy bearing in flange size, straight bushes and wear plate or thrust washer.

Standard-Stocked Alloy Bronze Brass Bearing, and other self-lubricating bronze bushing.

Cast Bronzes – Bushing, Bearings・Flange Size: Rg7 material equivalent: C83600, CC491K, CuSn5Pb5Zn5, CW452K, JM1, LG2, NS16530, Rg5, SAE40, UE5Pb5, UNI-BSZn5

Your Reliable Source for CuSn7Zn4Pb7-C (RG7) bronze bushing & bearings Ex Stock. Product Range Cast bronzes, RG7, CC493K, CuSn12-C, CC483K. Download Catalogue. Make An Enquiry. View News. Highlights: Catalogue Available, Online Enquiry Option Available.

Find a C93200 Bronze Parts, SAE 660 bronze bearing, Customized according your drawings.

Bronze Bushings Chemical Composition according to ASTM B505/B505M-18. More Rg7 bronze bearings products from china, Copper, brass, bronze and special alloys

* STANDARD-STOCKED PRODUCT/ ASTM B505 bronze bearings,