Self-lubricating bearing industry overview

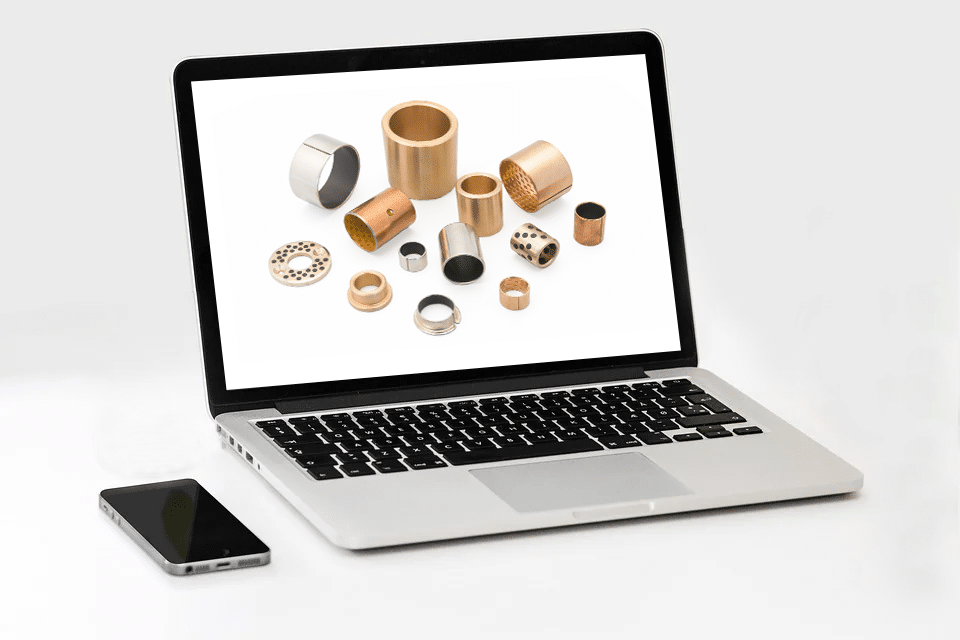

Bearings and Bushings for the Future: Precision and Customization: Our company, in bearing engineering with decades of experience, designs and develops high-precision self-lubricating bronze bearings & plain bushes. We offer a wide array of sliding bearings tailored to meet specific needs. Renowned for our expertise in custom bronze bushing and slide plate solutions, we provide an expansive selection of bushing metal alloys. Contact us today to benefit from unparalleled services at competitive prices.

Self-lubricating bearing industry overview

Product Selection Guide

Innovation. Commitment. Quality.

Self-lubricating products are ideal for a multitude of applications where components are inaccessible as lubrication is unnecessary. These products are offered in different sizes and configurations, giving them the ability to be designed to satisfy customer’s needs.

Well-chosen industrial products, authentic and quality products

All varieties from standard bearings product to customized bushings products

Self-Lubricating Bearing & Bushing Materials.

Your Partner for Sliding Bearing Technology.

Properly specified, self-lubricating bearings reduce maintenance costs, extend bearing life, and are more environmentally friendly.

We offer High performances for plain bearings at the best price.

Grease-Free. Zero Maintenance for Life.

Choose from our selection of self-lubricating bushings, including sleeve bearings, flanged sleeve bearings, and more. In stock and ready to ship.

Bearing Stay up to date

Custom Design, Engineering Support, Short Lead Times

Self Lubricating Bushings at Best Price in China

The development trend of self-lubricating bearings:

The production technology of self-lubricating bearings began in the United States.In the 1950s, PTFE (polytetrafluoroethylene) was gradually tested as a raw material for rolling bearings in the United States, and the sintering method of copper powder was also promoted.In 1956, the world with PTFE as the lining, with thick steel plate as the support point of self-lubricating DU rolling bearings into the market.At the end of the 1960s, self-lubricating bearings gradually entered the main use of cutting-edge technology such as aerospace.From the 1970s, American self-lubricating bearing manufacturers gradually approved the technology to enterprises in Holland, France, Japan and the United States. This measure promoted the rapid development trend of global self-lubricating bearing field, and self-lubricating bearings gradually entered the whole machinery and equipment manufacturing industry.

Self-Lubricating (Lubrication Free) Bushings

Self-lubricating bushings (lubrication free bushings) are made up of one of four basic compositions:

- Strong Cast Bronze with Solid Lubricants

- Bronze Wrapped Bushings

- Bronze Powder with Steel Material

- Sintered Bronze

With the development trend in the field of self-lubricating bearings, the production process and raw materials of self-lubricating bearings keep pace with The Times, and the types of commodities are gradually rich and colorful. According to the difference of product structure and production and manufacturing raw materials, self-lubricating bearings are divided into three categories: laminated, single-sided and other categories, which are divided into several subcategories.The actual results are shown below:

“Laminated” self-lubricating bearing products are made of two or two kinds of different kinds of rolling bearing raw materials stacked composite, in which the lining raw materials have the effect of self-lubricating bearing, the plate has the effect of supporting point, and other raw materials have the effect of connecting and connecting. The actual wetting effect of the “multilayer” commodity is of high quality, and its bearing capacity is determined by the tensile strength of the surface material.According to the type of sheet material and lining material, it can be divided into metal material sheet and metal material lining layer, metal material sheet and non-metal material lining layer and non-metal material sheet and non-metal material lining layer.

“Single type” self-lubricating bearing products is made from a variety of rolling bearing raw materials, Viiplus authorized dealer of goods with the aid of rolling bearing with self-lubricating bearing raw material in the raw materials such as high purity graphite, molybdenum disulfide, ptfe, lead etc. In order to develop RunHua, according to the type of rolling bearing raw materials, can be divided into metal materials and nonmetal materials. Non-metallic material single-sided self-lubricating bearings include the overall non-metallic material rolling bearings, non-metallic material production rolling bearings, etc. Metal material single-sided rolling bearings include solid – state embedded products and oil – containing products.” Solid embedding type” self-lubricating bearings are produced and processed in advance on the metal material sheet according to a certain ordering method, and then solid lubricants are placed in them; In the whole process of work, because of the effect of friction heat or working temperature, solid lubricant is slightly prominent on the rolling surface, and according to the friction, transfer film is produced on the metal material sheet and layer transfer surface, thus having the effect of reducing wear and abrasion. “Oil content type” self-lubricating bearing is the metal powder according to the powder non-metallurgical processing technology to inhibit the calcination into a porous structure of raw materials, and then fill the porosity with grease; In the whole process of work, due to the effect of friction heat or working temperature, the grease is precipitated from the rolling bearing, and the grease film is produced on the metal material sheet and layer transfer surface, thus having the effect of reducing wear and abrasion.

Self-lubricating bearings are suitable for fields where oil is not available or difficult to be fed. Because of the rules of the unique production process, some major equipment of the automotive industry, mechanical engineering company must work in extreme conditions, because the machine equipment, high working temperature, smoke or acid alkaline etching vapour in the air, and other factors, can’t add grease for machine equipment, and roller bearing or general rolling bearing friction damage more serious, It is easy to bite or kill rolling bearings, cause damage and destruction of parts, and cause the machine and equipment to stop operation.In order to make the continuous operation of production and manufacturing better, besides the installation of several machines and equipment in the initial design scheme, it is also necessary to invest a lot of maintenance personnel, spare parts and huge energy consumption. Therefore, companies in the automotive industry, engineering machinery and equipment, machining industry, etc. have the requirements for special moistening raw materials under the complicated working conditions and standards.Oil-free can greatly simplify the rolling bearing design and structure, control the cost, save the design time, can not maintain or less maintenance in the application of rolling bearings, but also avoid the risk caused by the lack of oil.

Because self-lubricating bearings do not need to provide oil equipment, they do not need to supply oil in the whole process of work, which can save a lot of installation and operation costs, improve physical properties, improve service life and stability.No oil will never use waste oil treatment solution, but also beneficial to ecological environmental protection.The strength of self-lubricating bearings for grinding shaft is relatively low, thus reducing the difficulty of production and processing of related parts.In the structure of self-lubricating bearing composite bearing, the surface can be electroplated with a variety of metal materials, which can be used in etched substances.In addition, because the diaphragm vacuum pump wetting does not have the problem of vegetable grease evaporation, self-lubricating bearings can be used in ultra-high pressure natural environment.

Self-lubricating bearings do not need to provide oil maintenance, wear resistance, high temperature resistance and other characteristics to greatly expand the scope of application of goods, many general rolling bearings can not serve as the industry can apply self-lubricating bearings, so self-lubricating bearings have a wider development trend than general rolling bearings indoor space.

| The installation | Rate | The friction factor | Noise | Moisturize | Sealing | Corrosion resistance | |

| Rolling bearing | high | Low or medium speed | small | Exercise is basically noise-free | It can be moistened or not | It can be sealed or not | good |

| Roller bearing | high | Low or medium speed | big | Exercise is basically noise-free | Must be moistened | Must be airtight | good |

| Self-lubricating bearing | low | Able to do high and medium speed fitness exercises | little | It makes noise when you work out | Must be moistened | Must be airtight | Not so good |

| Resistance to impact | Tolerance matching | Movement way | The provisions of the shaft | Customized non-standard specifications | |

| Rolling bearing | good | It can be exchanged with roller bearings in conditions approved by application standards | Parallel lines, rotates, oscillates, or forms of motion | The strength specification for the shaft is not high | handy |

| Roller bearing | good | It can be exchanged with roller bearings in conditions approved by application standards | Parallel lines, rotates, oscillates, or forms of motion | The strength specification for the shaft is not high | handy |

| Self-lubricating bearing | Not so good | It can be exchanged with rolling bearings under conditions approved by application standards | A single mode of motion in parallel lines, rotations, or oscillations | The shaft has a higher strength, need to carry out heat treatment process on the shaft | Inconvenience and high cost |

Imported composite dry sliding bearings are divided into flip (friction) bearings and sliding bearings according to the difference in friction characteristics. It goes without saying that rolling bearings are undoubtedly smaller than sliding bearings with lower frictional resistance, faster start-up, and high efficiency. This is the advantage of rolling bearings. Compared with sliding bearings, rolling bearings have large axial specifications, weak damping capacity, low service life at high speeds, and loud noises. Defects of self-lubricating bearings in high-end gearboxes. The most basic structure of the sliding bearing is divided into the piston pin and the motor shaft (the simple structure is very obvious). Rolling friction and flipping friction are essentially different (one is point contact and the other is surface contact), which also has substantial advantages and disadvantages.

Advantages:

1. High bearing capacity; (due to the large total contact area)

2. Simple structure, convenient manufacturing, production and processing, disassembly and assembly;

3. Excellent impact resistance and excellent vibration absorption characteristics, stable operation, high precision rotation .

Defects:

1. Complex maintenance and high requirements for lubrication standards;

2. The bearing is lubricated at the limit, causing great friction damage. (This is also the disadvantage of the large total contact area) The application of sliding bearings is: high-speed, high-precision, light load, or even in equipment with low-speed impact. In addition, it is believed that most places use rolling axis.

Join Over 500,000 Customer Enjoying Buying Self-lubricating Parts Now

Always tested. Always proven. Always VIIPLUS.com

Solutions For Every Industry

Searching for Dependable Bushing Solutions? viiplus Has What You Need.

Design Guides, Materials

Bushing design, Comprehensive design manuals covering a range of self-lubricating materials used in all of viiplus’s manufacturing processes.

Technical Guides

Manufacturing On Demand, Technical Guides For Machining Design. Discover the latest in metal alloys, materials, and design tips for manufacturing custom machined and self-lubricating bearing parts.

Get Instant Quote

To receive your instant quote, simply upload your drawing file and choose your production process & bushing material.

Prototyping, Place Order

After you place your order, we will start the production process. You will receive updates when your order has completed production and is ready to be dispatched.

Receive Your custom Parts

We provide precision-inspected high-quality parts, packing lists and documents, and delivery tracking.