Self-lubricating Bearings for Forklifts

Bearings and Bushings for the Future: Precision and Customization: Our company, in bearing engineering with decades of experience, designs and develops high-precision self-lubricating bronze bearings & plain bushes. We offer a wide array of sliding bearings tailored to meet specific needs. Renowned for our expertise in custom bronze bushing and slide plate solutions, we provide an expansive selection of bushing metal alloys. Contact us today to benefit from unparalleled services at competitive prices.

Self-lubricating Bearings for Forklifts

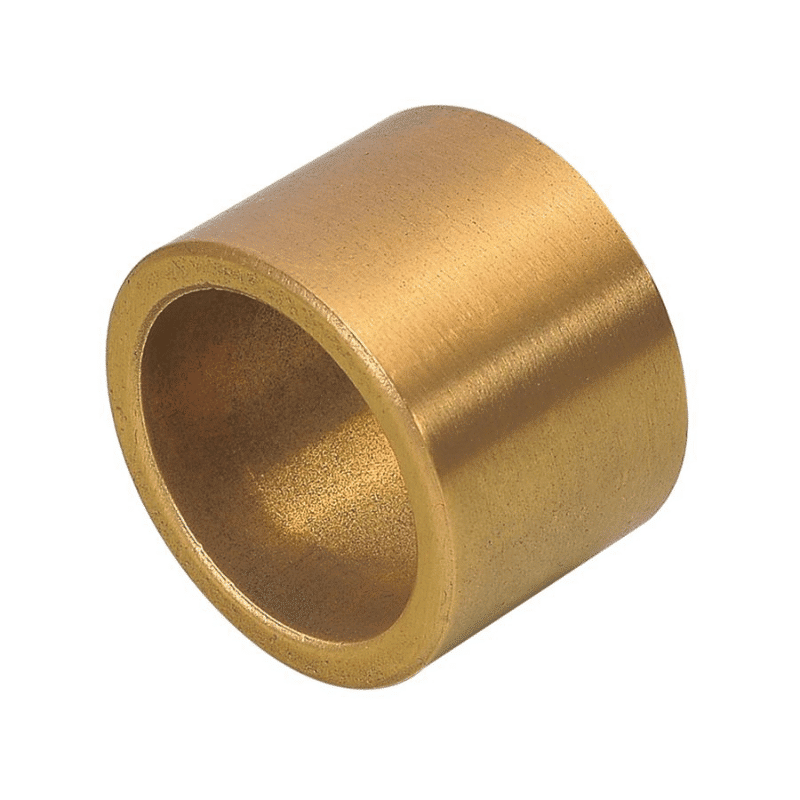

Metric Bushing, Forklift Parts, Bronze Graphite Self lubricating Bearing

Forklift Bushing

Bearing – Wholesale Suppliers Online, forklift parts supplier

Find Quality Products from Verified Suppliers. Get a Live Quote Now! Logistics Service. Production Monitoring. Most Popular. Trade Assurance. Types: Sleeve Bearing, Flange Bushing. Self-lubricating Bearings for forklifts – Quality forklift sleeve bearings! Our team has the oil-free bearing expertise and technical acumen needed to develop solutions that meet your individual requirements for self-lubricating bearings. We zhou’c to ensure proper sizing, application and mounting.

Industrial Sectors Solutions For Material Handling

POM Sleeve bushing

Storing high loads without lubrication, Lifting tables may not be the most impressive, but they are an indispensable system in intralogistics. They are used wherever loads need to be brought to an ideal height. In some cases, self-lubricating bearing points are exposed to high loads due to load capacities of up to several tons and high stroke frequency in multi-shift operations. To work reliably, metal self-lubricating bearings are commonly used, especially when they are exposed to the outdoors. With self-lubricating plain bearings made from high-performance POM Bushing, you can extend the life of your lift table and reduce the costs associated with maintenance work. High wear resistance, Resistant to dirt, Cost-effective!

Product Quality Index

Energy Generation

COMMON FORKLIFTS BUSHING APPLICATIONS

Find your forklifts bushing, today. Forklift Truck Parts – Spare Bushing Parts. Field Services: We offer self-lubricating plain bearings solutions to help customers deign for your application. It is available for short delivery and long-term business partner to best meet your company’s needs. Our innovative custom size bearing bushing help make the installation fast and safe.

A Reinforced Self-lubricating Bearings Design Reduces Forklift Friction Failure, component design, material selection, prototype, production. In need of quality forklift self-lubricating bearings? Have a look at our wide range of bushing types & materials. Find the right forklift bearings in our stock. bronzelube.com, your business-to-business supplier. You can rely on self-lubricating bearing bushings for forklift parts When you need performance parts!

The lifting mechanism of the forklift truck consists of a lifting bar and a fork frame with 2 fork arms. The forks can be raised or lowered and adjusted laterally on the lift mast so that the goods can be easily positioned and held. The forks can be hydraulically moved by means of a skid plate.When positioning the pallet, severe shocks and asymmetric stresses act on the forks. Depending on the field of use, forklifts are subject to various environmental conditions, such as dust, humidity, cold or heat.

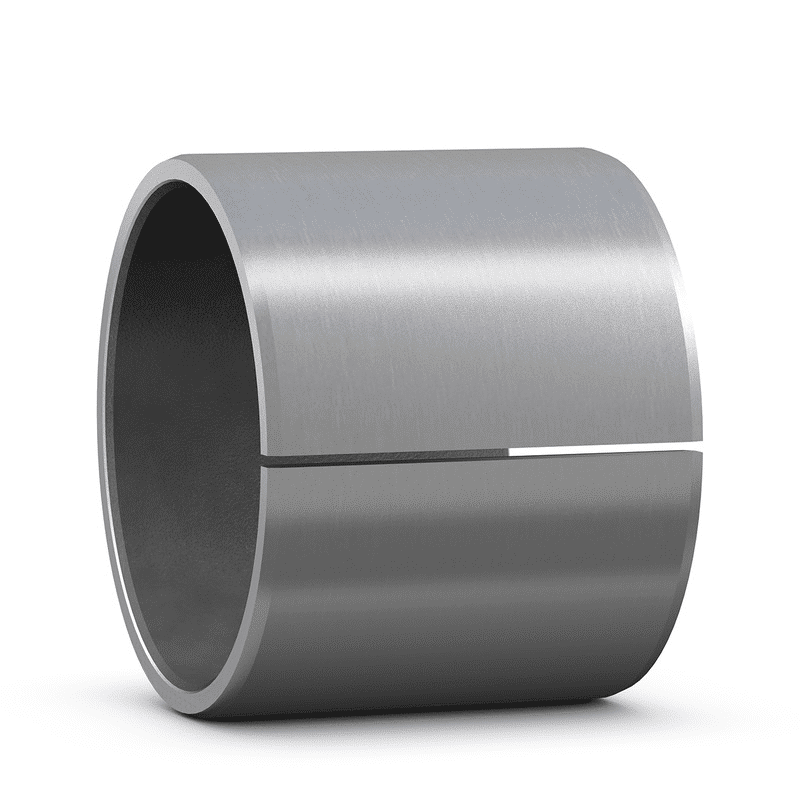

PTFE composite plain bearings

Long, maintenance-free service life due to low friction

Thrust washer and thrust bearings save costs for forklift company. is experiencing less downtime, expenditure. PTFE Lined Bush: PTFE composite plain bearings are the maintenance-free solution to premature bearing failure in heavy load/medium speed applications. Steel Backed PTFE composite plain bearings are maintenance-free and have very good frictional properties.PTFE composite plain bearings combine the mechanical strength of steel with the low friction of a self-lubricating lead-free sliding layer based on PTFE. To protect the bearing from corrosion, the steel backing is tin-plated. PTFE composite dry plain bearings are suitable for applications with heavy loads, and a sliding material with self-lubricating properties is a prerequisite.

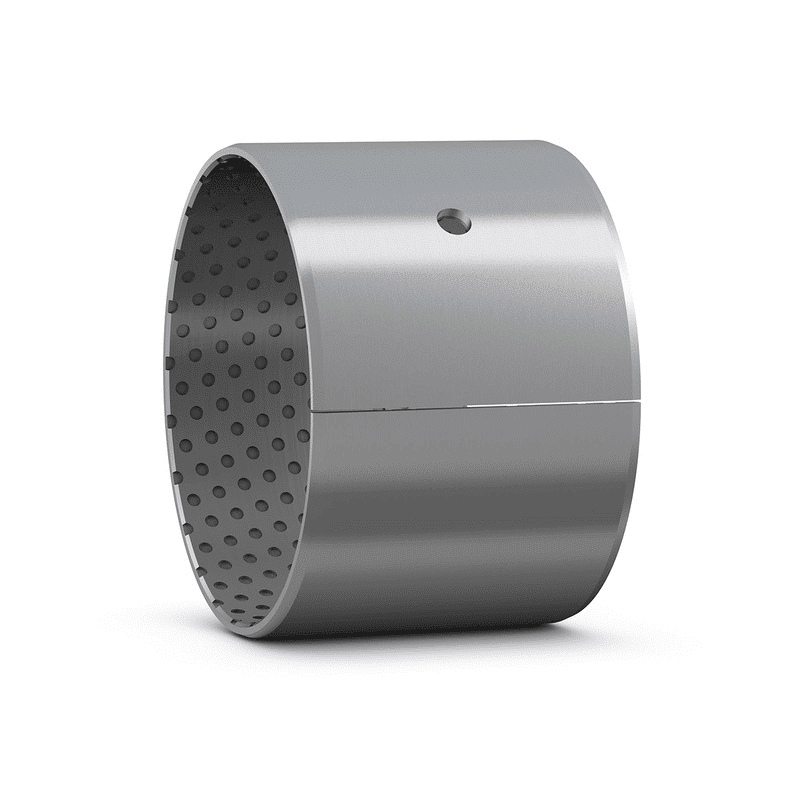

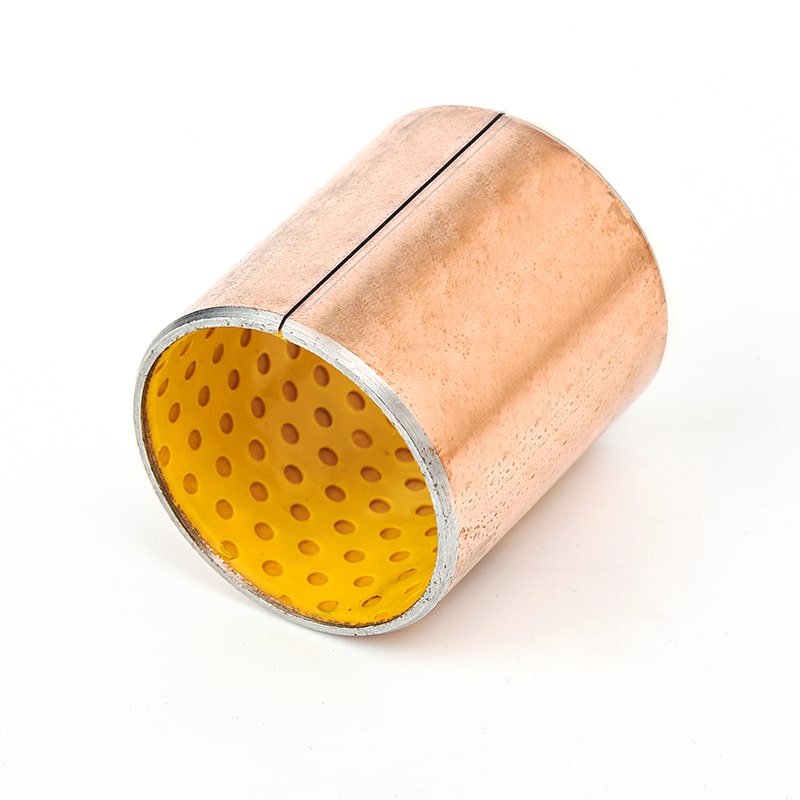

POM composite plain bearings

Optimized for minimal maintenance in difficult environments

Pom lined composite plain bush

Steel-backed POM composite plain bearings are called self-lubricating bearings because they require only a trace amount of lubricant to operate satisfactorily for long periods of time. The bearing material is designed to operate with marginal lubrication, effectively filling the gap between fully lubricated bearings and dry sliding bearings. Steel-backed POM composite plain bearings are maintenance-free and have very good frictional properties. They have high load carrying capacity and high sliding speeds.POM composite plain bearings are suitable for applications requiring minimal maintenance under difficult operating conditions. Due to the lubricant retention pockets on the sliding surfaces, POM composite plain bearings are particularly suitable for applications in contaminated environments where a continuous or frequent supply of lubricant is not possible.

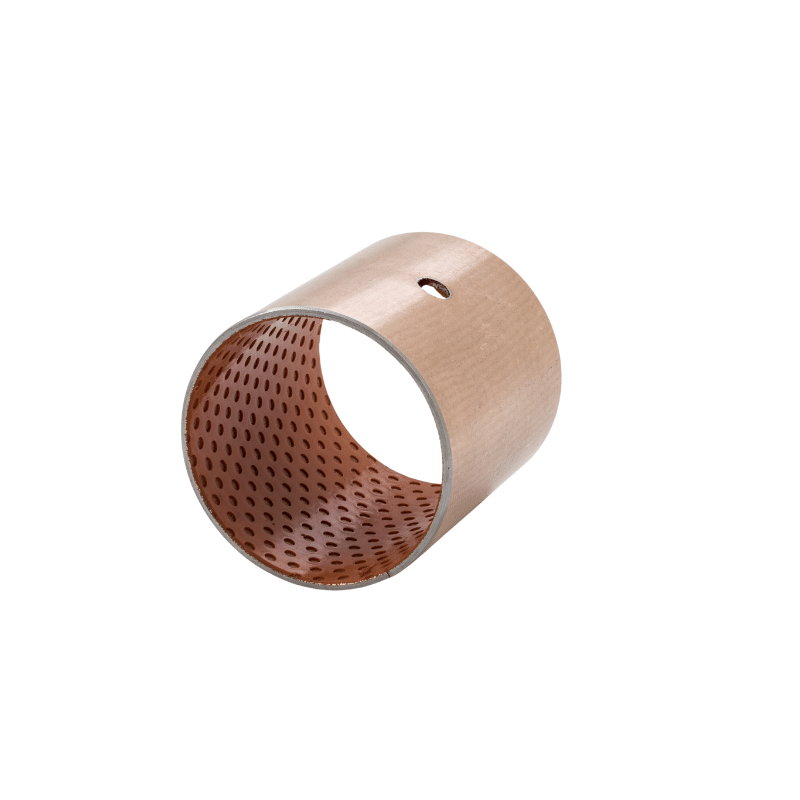

The traditional and robust

bushing material

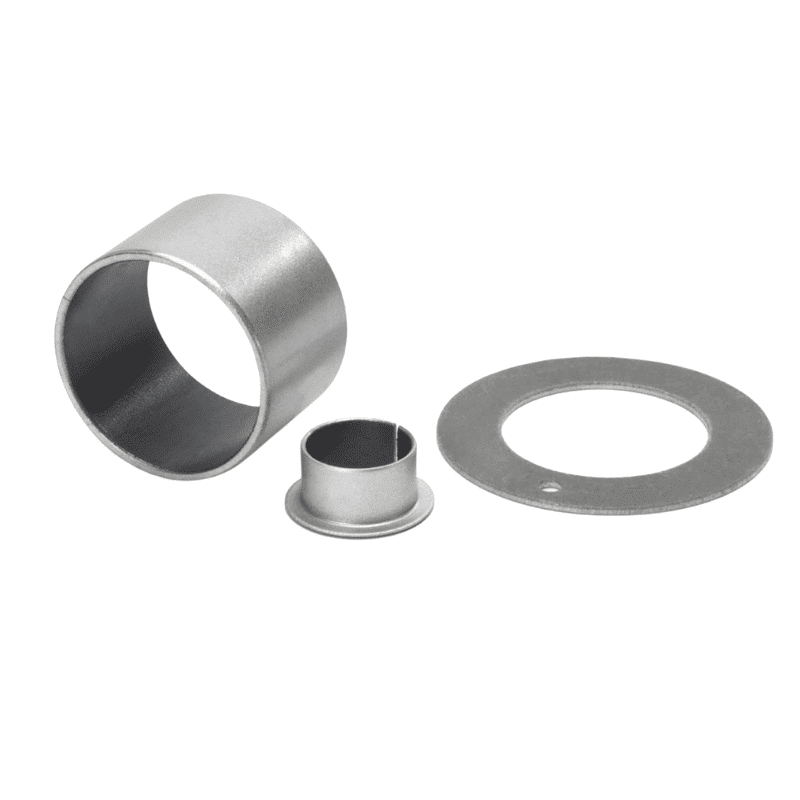

Multi-layer bearing,A wide assortment to

meet your needs

Specialist in fork truck Mast & Carriage Bearings. Large range for most makes of forklift. Specialists in Bushing Bearings. Large range available from stock. Always tested. Always proven. Forklift Bearing – Bushing Dealers Online. Bushings, thrust washers and strips. A wide assortment for virtually every application!

Composite Bearing Self-Lubricating Bearing Technology: When self-lubricating bearings can’t be repaired, we can help you solve the problem. With composite bearing self-lubricating bearing technology, you can bring new life to aging self-lubricating bearings at a fraction of the installation cost. Self-lubricating bearings reduce costs. Comprehensive service, including bearing design, parts, inspection and warranty. Processes managed by self-lubricating bearing application engineers and field service technicians. Customized self-lubricating bearings designed and installed in a faster, easier and safer manner

Experienced, Professional sleeve bushing tailored to your needs.

Polytetrafluoroethylene plastic multi-layer bearings with steel back.

Demonstrates superior friction performance under high load conditions. The self-lubricating bearings are composed of three layers: Polytetrafl fluoroethylene plastic layers with fillers, sintered bronze layers, and back steel.

Polytetrafluoroethylene (PTFE) plastic multi-layer bearings with back metals are a type of bearing used in forklift trucks. These bearings consist of alternating layers of PTFE plastic and metal, providing a combination of low friction and high strength. The metal back provides additional support and stability, making these bearings ideal for use in harsh industrial environments like forklifts.

Some of the benefits of using PTFE plastic multi-layer bearings with back metals in forklifts include:

Low friction: The PTFE plastic layers reduce friction, providing smooth and efficient operation of the forklift. This can improve the efficiency of the forklift and extend the operating time between charges.

High strength: The metal back provides additional strength and stability, allowing the bearing to handle heavy loads and resist wear and tear. This makes it ideal for use in forklifts, which typically have to handle heavy loads on a regular basis.

Durability: The combination of PTFE plastic and metal layers provides good wear resistance, ensuring long life for the bearing. This can reduce the need for maintenance and improve the overall reliability of the forklift.

Improved accuracy: PTFE plastic multi-layer bearings with back metals are designed for precise operation, providing accurate and reliable control of the forklift. This can improve the accuracy of the load handling and reduce the risk of damage to the load or to the forklift itself.

Corrosion resistance: The metal back provides additional protection against corrosion, making these bearings ideal for use in harsh industrial environments where corrosion can be a problem.

Overall, the use of PTFE plastic multi-layer bearings with back metals in forklifts can provide a range of benefits, including improved efficiency, durability, and accuracy. This makes them a popular choice for forklift manufacturers and operators who are looking to improve the performance and reliability of their equipment.

Multi-layer bearings with steel-backed feature

■ Serviceable without the need for lubrication. Thin and lightweight for compact design.

■ Demonstrate low coefficient of friction and superior load performance under high-load, low-speed conditions.

■ Usable at the PV values even in the middle- and high-speed zones when lubricated.

■ Usable in wide temperature ranges from low to high temperatures. Has superior chemical resistance.

■ Features superior dimensional stability, mechanical strength, and thermal conductivity.

■ The 0.5 mm thin standard steel self-lubricating bearing products are also available for space saving.

Multi-layer bearing for Forklift, Self-Lubricating Forklift Bushing Parts Availability.

A multi-layer bearing is a type of bearing that is used in a variety of applications, including in forklifts. In a forklift, the multi-layer bearing is typically used in the mast and carriage, as well as in the wheel or swivel unit. The purpose of the multi-layer bearing is to provide smooth and reliable operation of the forklift, allowing for precise control and maneuverability.

Multi-layer bearings typically consist of alternating layers of steel and plastic, providing a combination of strength and low friction. This type of bearing is also designed to handle high loads and resist wear and tear, making it ideal for use in a harsh industrial environment like a forklift.

Some common features of multi-layer bearings for forklifts include:

High load capacity: The multi-layer design provides a large contact area and high load capacity, allowing the bearing to handle the heavy loads associated with forklifts.

Low friction: The plastic layers in the bearing reduce friction, providing smoother and more efficient operation.

Durability: The combination of steel and plastic layers provides good wear resistance, ensuring long life for the bearing.

Precision: The multi-layer bearing is designed for precise operation, providing reliable and accurate control of the forklift.

Overall, the use of a multi-layer bearing in a forklift can improve performance, reliability, and efficiency, making it an important component in the design of modern forklifts.

Forklift Self-lubricating Bearing Parts – waiting the forklift bearing bushing for immediate supply – NO WAITING, so that you can keep your forklifts and products moving without any delays.

Always Bronzelube.com, Always self-lubricating, always long life.

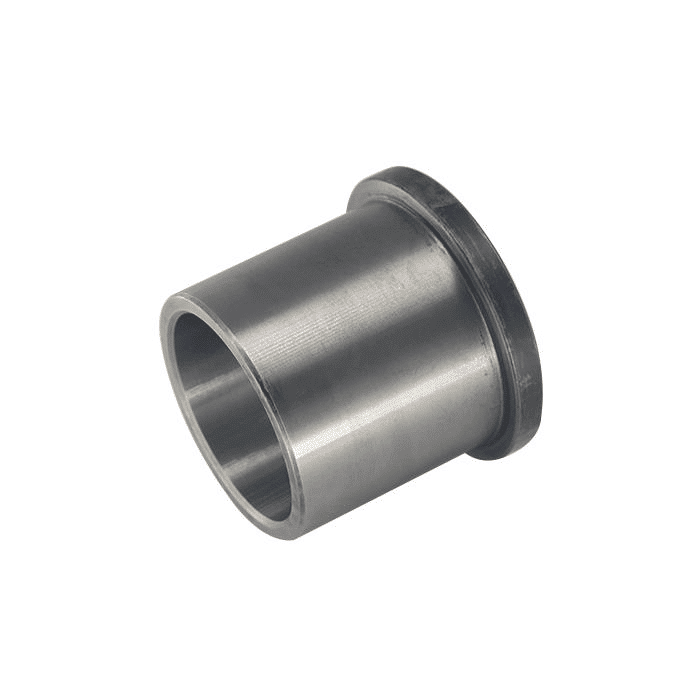

Forklift slide Bushings,Plain thrust bearing

Requirements for forklift bearings, Insensitive to shock and vibration

Insensitive to high edge loads with asymmetric stresses, Insensitive to extreme environmental conditions

- High operational safety

- Long service life

- Low maintenance requirements

- Sliding bearings and thrust spacers

The bearings used for the lateral adjustment guidance of the forks are low-maintenance plain bearing half shells made of composite materials. This ensures that the forks can be adjusted laterally without obstacles and without tilting. The smooth adjustment of the forks is guaranteed even under extreme environmental conditions and the maintenance requirements are low.

Advantages of sliding bearing half shells for forklift trucks

Sliding bearing half shells are a type of bearing used in forklift trucks to provide smooth and reliable operation of the mast and carriage, as well as in the wheel or swivel unit. The use of sliding bearing half shells in forklifts offers several advantages, including:

Reduced maintenance: Sliding bearing half shells are designed to operate with minimal friction, reducing wear and tear and extending the lifespan of the bearing. This can reduce the need for maintenance and improve the overall reliability of the forklift.

Improved efficiency: The low-friction operation of sliding bearing half shells can improve the efficiency of the forklift, reducing energy consumption and extending the operating time between charges.

Improved accuracy: Sliding bearing half shells are designed for precise operation, providing accurate and reliable control of the forklift. This can improve the accuracy of the load handling and reduce the risk of damage to the load or to the forklift itself.

Cost-effectiveness: Sliding bearing half shells are typically more cost-effective than other types of bearings, due to their simple design and low maintenance requirements. This can make them an attractive option for forklift manufacturers and operators who are looking to reduce costs.

Easy installation: Sliding bearing half shells are easy to install and replace, making it simple to maintain the forklift and keep it operating smoothly.

Overall, the use of sliding bearing half shells in forklifts can provide a range of benefits, including improved efficiency, reliability, and cost-effectiveness. This makes them a popular choice for forklift manufacturers and operators who are looking to improve the performance and durability of their equipment.

- High wear resistance

- High resistance to compression

- Smooth running

- Constant and low friction values

- Insensitive to shocks and impacts

- Insensitive to dust and moisture

- Insensitive to high edge loads

- Low maintenance operation with lubrication

Bearings in forklifts: Guidance for lateral adjustment of forks

Industrial Bearing Bushing, Forklift technology, transport equipment construction, warehousing technology。 Products type: Cylindrical bushings plain bearings PTFE plain thrust bearings

Application: Forklift trucks are used to lift, transport and unload goods on pallets, for example, in logistics and manufacturing companies.

A Reinforced Bearing

Design Reduces Forklift

Friction Failure

Specialists in carriage and chain self-lubricating bearings. The large range is available from stock. Technical Sales are available to help with identification. Custom sizes on request.

A partnership with bronzelube.com gives you a competitive edge.

Plain Bearings for forklifts – Delivered to your location

Warehouses depend on their forklifts to move cargo efficiently so they can deliver goods and meet tight shipping deadlines. After all, equipment productivity has a direct impact on warehouse profits.

Chemical properties: The surface polymer is resistant to chemical corrosion, so its corrosion resistance mainly depends on the steel back and the surface plating. Copper or tin plating on steel back surface can effectively prevent atmospheric corrosion; If working in the corrosive medium, steel back can be galvanized, etc.

Bronzelube.com provides engineering, custom fabrication and manufacturing of high-performance plastics and self-lubricating bearings materials.

Bearings Solutions

Customized For Quick Learning

MATERIALS

- Wrapped composite sliding bearing, tin-plated steel/PTFE or POM, DIN 1494/ISO 3547, Maintenance-free

TECHNICAL DETAILS

- Specific load capacity static≤ 250 [N/mm2]

- Specific load capacity dynamic≤ 140 [N/mm2] at low sliding speed

- Sliding speed≤ 2.5 [m/s]

- Friction value0.03 [µ] to 0.25 [µ]

- Temperature strain-200 [°C] to +280 [°C]

- Max. PV-value1.8 [N/mm² x m/s] 3.6 [N/mm² x m/s] for short time

Why Choose Self-lubricated Plain Bearing?

MAINTENANCE PLAIN BEARINGS

Why chose bronzelube’s innovative bearing engineering?

Dual-layer design to stop friction erosion

Automatic correction of shaft misalignment

Self-lubricating design for longer bearing lifecycle

Good tolerance for variable loads

Housing ØH7

Bushing inner-Ø after mounting

in the range of D Shaft tolerance h8

Metal-Polymer Plain-Bearings for for forklift trucks

high performance self-lubricating bearings

Plain-Bearings for forklift trucks

Special dimensions are available on request

*If you like to use lubrication nonetheless, please remember to lubricate the sliding bearing regularly.

Special dimensions are available on request

*If you like to use lubrication nonetheless, please remember to lubricate the sliding bearing regularly.

Bushing size chart bushings catalog

Search Bushing Size Chart. Get The Best of the price of bushing parts,

Du, Dx Bushings Catalog – Search Du, Dx Bushings Catalog, Split Type

From prototype to production.

• Self-Lubricating

• High Load | High Speed

• Metal Backed Bearing System

Engineering Plain Bearings Custom Fabrication Bushings Manufacturing

Engineered Self-lubricating Bushing Solutions

• Self-Lubricating

• Low weight | High Strength

• Low Coefficient of Friction

• Chemically Resistant

• 100% Lead-Free

SEARCH BEARINGS BUSHINGS SIZE

Bushings Catalog – Search Bushings Catalog, Bushes – Metric –

CAD DRAWINGS

Get access to dx bushing equivalent drawings

Self-lubricating forklift bushing parts high quality, forklift parts supply!

Our after market plain bearing bushing parts suppliers are carefully chosen so we don’t compromise on the quality of the self-lubricating bearing parts – we have managed to find the perfect balance between the price of the product and the longevity of the parts.

Solutions For Every Industry

Searching for Dependable Bushing Solutions? viiplus Has What You Need.

Design Guides, Materials

Bushing design, Comprehensive design manuals covering a range of self-lubricating materials used in all of viiplus’s manufacturing processes.

Technical Guides

Manufacturing On Demand, Technical Guides For Machining Design. Discover the latest in metal alloys, materials, and design tips for manufacturing custom machined and self-lubricating bearing parts.

Get Instant Quote

To receive your instant quote, simply upload your drawing file and choose your production process & bushing material.

Prototyping, Place Order

After you place your order, we will start the production process. You will receive updates when your order has completed production and is ready to be dispatched.

Receive Your custom Parts

We provide precision-inspected high-quality parts, packing lists and documents, and delivery tracking.