Bronze Bushings Available – Order Today

Oil less brass bushing

We are dedicated to providing cost-effective, reliable oilless brass bearings and bushings. Reach out to us for worldwide, on-time shipping and explore our product range. Contact us today for guaranteed 100% quality, exceptional stability, and long-term wear resistance. We can efficiently customize bushings in virtually any size, including sliding plates. Prefer bush bearings? Place your order with our China-based supplier today!

Oilless Bushing Manufacturing

Morbi leo sagittis placerat sem. Nisl tincidunt nulla fames nisl risus egestas.

We’re engineers and innovators who solve our customers’ most critical challenges. Total Reliability – Long-Term Reliable Supplier! CAD Downloads – Bronze bushings! Customizable Bushings and Washers. Various Types, Materials, Sizes, Finishes, and More. Large Selection of Bushings and Washers. Oilless Washers, Flat Bronze Washers, and More.

Oilless Bushes, Price and Delivery Time On Request!

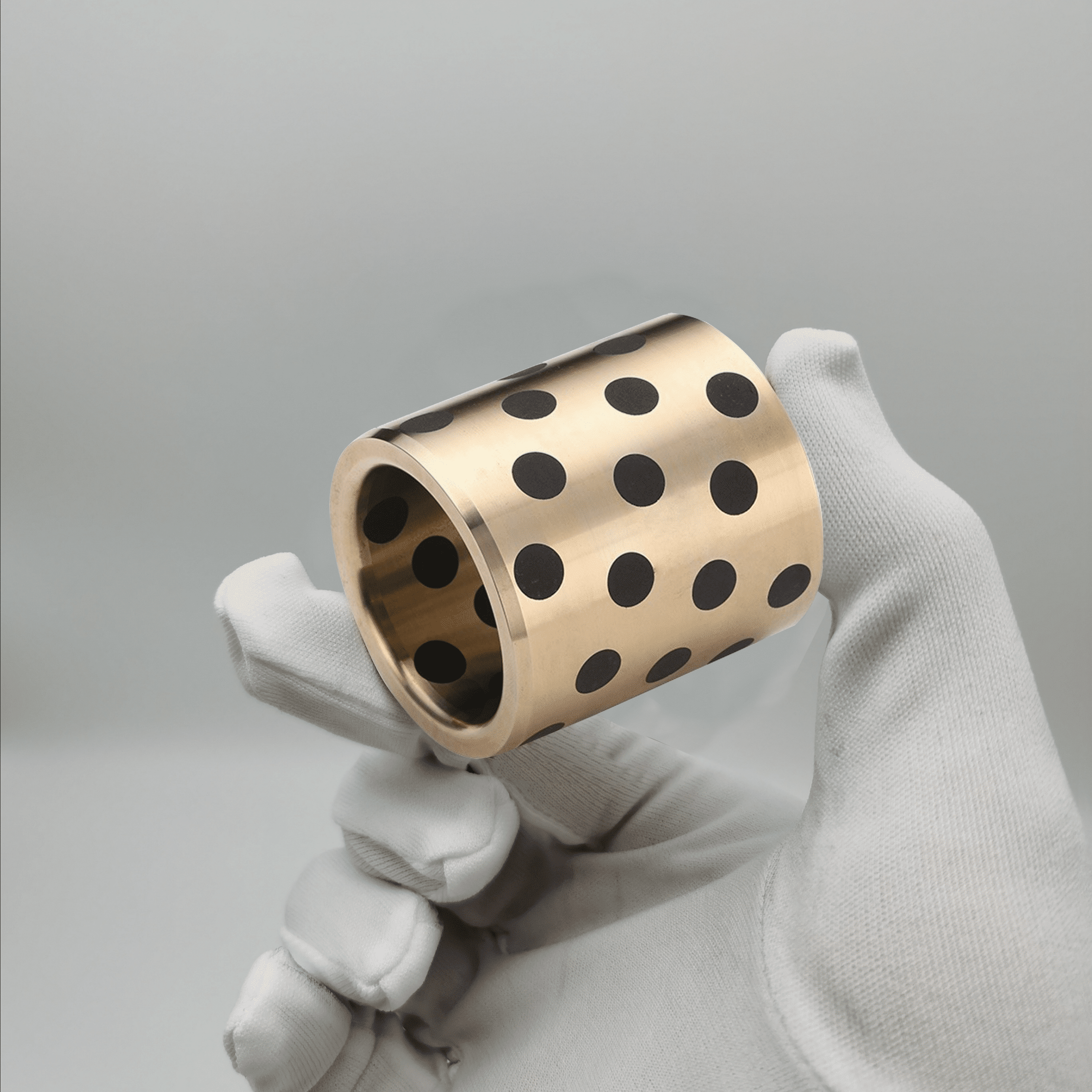

Our standard products include maintenance-free flanged bushings made from bronze with solid lubrication, available in thin-walled designs. Bronze rings can be enhanced with graphite inserts, which are added during casting for effective solid lubrication. Explore our inventory of bronze plain bushings, ready to order today.

Oilless bushes are versatile, self-lubricating bearings that eliminate the need for external lubrication, providing a maintenance-free solution across numerous applications. Their industrial versatility includes features like free CAD downloads and competitive pricing. Commonly known as sleeve bearings, they effectively support sliding movements in mechanical systems.

Materials: Our bushings are made from high-quality materials such as PTFE, copper alloy, and bronze to suit diverse industrial needs.

Custom Parts Services and Prototyping!

Special Bronze Alloys And Aluminium Bronze Bearing, Search Our Material Alloy

High Performance Self-Lubricating Bearings

Oilless Bearing Is A Self-Lubricated Bearing Using High Grade Bronze Alloys As Their Base Material, With Embedded Solid Lubricant Plugs, Graphite Or PTFE.We offers free CAD downloads, short lead times, competitive pricing, and small minimum order quantity. Oiles Flange Bearing and Bearing Pads! Oilless bearings are made of ultra-hard, durable bronze with built-in self-lubricating graphite plugs for maintenance-free operation. These bearings are an excellent solution when it comes to high loads and small movements where lubrication is difficult to implement. The graphite plugs cover approximately 25-30% of the bearing surface and are positioned so that the entire bearing surface is always lubricated.

Order Oilless Bearing Online:

Ordering this Oilless Bearing is easy and fast!

We offer high stock levels of Oilless bearings for applications in Hardware and steel manufacturing, stamping dies, tooling components for the automotive industry and sheet metal stamping. Most of them are available for immediate delivery online.

Optimize your budget for oilless bushings and thrust bearing washer plates to support your project’s needs.

Standard Oil-less Brass Bushing- Solid Lubrication Oilless Production, Plain Bearing Bushes. Get started with a trial order, Always tested. Always proven. Oilless Metal Sliding Materials!Keep your machinery running smoothly with our friction-reducing oilless sleeve bushings. Precision-engineered for wear resistance and optimal performance. Contact us today!

Oilless Bearing Features

- Oilless Bushes are maintenance free (self-lubricating)

- Oilless Bush for heavy-duty applications

- Oilless Bronze Bearing withstands extreme temperatures

Oilless Plain Bushing Long life

Standard Components for Sliding Material, Oilless Bushing Bronze Castings, Solid Lubricant

“Copper Alloy, Solid Lubricant oil-less bushings supplier.”

We specialize in oilless bearings, offering a wide range of straight bronze castings. Our customized copper bushings are available in various specifications, crafted from high-quality materials like tin bronze, aluminum bronze, high-strength brass, lead bronze, and other copper-based alloys. We manufacture according to your drawings. Order custom-made oilless bushings directly from our China-based supplier, available for online purchase.

Type Of Bearing

Oilless Bearing Material

Oilless Material Design, Self-Lubricating Oilless Bushings – No More

Oilless Bearing Material Design, Request a Quote or Place an Order! LubricationReduce maintenance downtime with self-lubricating oilless sleeve bushings. Perfect for high-load applications. Order yours for smooth, efficient machinery operation! Industrial Oilless Bushings – Lasting Performance: Our high-quality oilless sleeve bushings deliver excellent wear resistance, corrosion protection, and longevity. Request a free quote now!

| ZCuZn25 AI6Fe3Mn3 |

ZCuSn6Zn6Pb3 | Metallic Bushing | Bushing | Bushing | |||

|---|---|---|---|---|---|---|---|

| GB1776-87 | ZCuZn25 AI6Fe3Mn3 |

ZCuSn6Zn6Pb3 | ZCuAI10Fe3 | ZCuSu10P1 | Steel+ZCuSn6Zn6Pb3 | HT250 | GCr15 |

| ISO1338 | GCuZn25 AI6Fe3Mn3 |

GCuSn6Zn6Pb3 | GCuAI10Fe3 | CuSn12 | Steel+CuSn6Zn6Pb3Fe3Ni5 | – | B1 |

| DIN | G-CuZn25 AI5 |

GB-CuSn5Zn5Pb5 | GB-CuAI10Ni | GB-CuSn10 | Steel+CuSn6Zn6Pb3Ni | – | 100Cr6 |

| JIS | HBsC4 | BC6 | AIBC3 | BC3 | BC6 | FC250 | SUJ2 |

| ASTM/UNS | C86300 | C83600 | C95500 | C90800 | C83600 | Class40 | 52100 |

| BS | HTB2 | LG2 | AB1 | PB4 | LG2 | – | – |

Order Self-Lubricating Components Online

About This Item

- Material: Constructed from cast brass and embedded with graphite for self-lubrication, eliminating the need for oiling. The components boast strong load capacity and wear resistance.

- Function: Known as plain bearings or bushings, they primarily guide or minimize friction in linear applications.

- Application: Widely used in industrial equipment, including electrical devices, household machinery, printing presses, and machine tools.

We provide bushings directly from China with CAD downloads, quick lead times, competitive pricing, and small minimum order quantities.

Our Self-Lubricating Components

Our self-lubricating components are engineered to control linear motion under substantial loads. Suitable for various applications like molds, fixtures, special machines, and heavy equipment, our products are designed for long service life, often surpassing the life span of the machines on which they are installed. Most of our components are ordered for new constructions.

Direct Wholesale of Self-Lubricating Components

While initially pricier than conventional parts, our self-lubricating components offer long-term value due to their built-in lubrication, eliminating the need for extra oil or grease. Over time, they prove cost-effective by reducing periodic lubrication costs and the risk of inadequate lubrication.

Graphite Self-Lubricating Oilless Bushings

Graphite plugs provide efficient, permanent lubrication. Graphite’s two-dimensional crystalline structure allows it to easily shear off into parallel sheets, making it an ideal lubricant. As two mating surfaces interact, graphite flakes are distributed across the wear surface, creating a solid lubricant layer that remains stable and effective for a long time.

Graphite sublimates at extreme temperatures but oxidizes in air around 500°F, so operating below this temperature is crucial. Graphite has a near-zero coefficient of thermal expansion, meaning it won’t expand even as the surrounding metal does, preventing thermal misalignment of the plugs.

Additional Lubrication Tips

Extra lubrication isn’t usually recommended for self-lubricating components. However, light oil can be applied to new parts for a few initial cycles to distribute graphite more evenly. Beyond that, adding lubrication can attract dust and grit, hastening wear. Grease, in particular, should be avoided as it may damage the graphite shaft bearing bushings.

Bushing – Brass Alloy, Straight Oilless Bushing

Our bushing material, graphite-impregnated brass, is available as both plain and self-lubricating bearings. Find them at bronzelube.com, where you can download CAD files for free and benefit from quick lead times. Achieve reliable performance with customizable oilless sleeve bushings, suitable for various industries. Contact us for tailored, self-lubricating bearing solutions!

Graphite Bushings and Bearings

We Supply Oilless Brass Bushing Tailored To Your Needs. Plain Shaft Bearings, Oilless bush – Oilless Self-lubricating Tech. 00% Quality Guaranteed. Worldwide On-time Shipping. View Our Products.

Material: Special Brass Oilless Self-lubricating Bushings.

Lubricant: Graphite, Our range of oilless bearings is ideal for projects where lubrication is difficult to provide or where traditional lubricants might carbonize. Designing oil-feeding systems can be both time-consuming and costly. By eliminating the need for these systems, our oilless bearings significantly reduce maintenance and oil costs.

Maintenance free bearing and guide bushes, bronze with solid lubricant.

-

Custom-made products. Straight type, flange type! Straight, Bronze Castings type. Oilless bushing suppliers, a range of oilless bushings that has gained an excellent reputation for reliability and performance. Maintenance free bearing and guide bushes, bronze with solid lubricant. Explore More oilless bushing products from china

What are oil-free bearings made of, Oilless Bearings, Composite Slide Bearings ?

Oil-free bearings are usually made of bronze powders that are fused together to form a porous surface in which impregnated oil can be stored. As the bearings are used, oil is continuously circulated to the surface of the oil-free bearings, making them self-lubricating and justifying the name “oil-free bearing“. Self-lubricating bearings, maintenance-free …oilless bearings benefit from outstanding chemical and corrosion resistance.

Sed porttitor lectus nibh. Vivamus magna justo, lacinia eget consectetur sed, convallis.

CuZn25Al6Mn4 Bronze with solid graphite lubricant inserts (alternative specifications are available on request)

Copper Bushing Supplier – Oilless Self-lubricating Tech. Lubrication-free bushings come in a variety of shapes that can be used for different applications as needed. Examples include straight bushings, collar bushing, flange bushing and thrust washer…

Standard Components for Sliding Material, Oilless Bushing Bronze Castings, Solid Lubricant

“Copper Alloy, Solid Lubricant oil-less bushings supplier.”

Explore More Straight, Bronze Castings Type, Customized production of various specifications of copper bushings, product materials cover tin bronze, aluminum bronze, high force brass, lead bronze, brass and other copper-based alloy materials, customize the production of drawings. Oilless Bushes Made To Order From China Supplier, Online Sales.

Hi Temp Oilless Free Brass Bearing Solution.

High Quality And Service. Work in High Temp & Submerged Applications Where Grease, Oil & Plastics Fail. Non-galling. Increased reliability. Reduced costs & downtime. JDB ZCuZn25 AI6Fe3Mn3 Solid Inlay Bearing. The wear-resistant metal material is used as the substrate, and various lubricating materials are added to reduce the friction factor and achieve self-lubrication. This material structure combines the advantages of high load of metal, good impact resistance and low friction coefficient of non-metal, and can meet the use of various working conditions. According to the different distribution of solid lubricant, it is divided into inlay type with regular arrangement according to certain ratio and ...

Self Lubricating Bearings No Oil Or Grease , Plain & Self-Lubricating Bearings

Oil-free brass bearings are manufactured from a material that contains its own lubrication in the form of plugged graphite. These types of brass bearings are also referred to as self-lubricating bearings. As a result, the brass bearings do not require oil or external lubricants to operate optimally. Ideal for High Temps · Our Advantage, Bearings for High Temps ·