providing factory services of superior quality with focus on efficiency.

01.

Providing Quotes for Custom Parts and Large-Scale Production Orders

02.

Satisfaction guaranteed

03.

Ensuring timely delivery

04.

Revolutionize How You Produce Custom Components

We Stand by Your Side from Initial Prototyping through to Production and Further.

Bushing assembly, How to repair and install oil-free sliding bearings?

What are the installation instructions for oilless bearings?

1. It should be determined whether there are bumps, protrusions, etc. on the mating surface of the shaft center and the shaft shell.

2. Confirm whether there is dust or mold sand attached to the surface of the bearing shell.

3. In order to avoid bumps during installation, a small amount of lubricating oil should be applied to the surface of the shaft and shaft housing. When installing the bearing on the shaft center, force must be applied to the inner ring, and when installing the bearing on the bearing shell, force must be applied to the outer ring. When applying force to the bearing, be careful to make the force go down vertically and evenly, and the bearing will be injured by eccentric hits, so try to avoid eccentric hits.

4. The retainer of the oil-free bearing and the sealing plate and the oil-free bearing must not exert force. The installation method of using a hammer and a casing is a commonly used method because it will damage the bearing, so do not hit it directly. It should be struck with the sleeve in the middle, and the hammer should be struck lightly. In the mechanical structure, when the inner and outer rings are tightly fitted, the backing plate should be used, and the self-lubricating bearing must be used so that the force can be added to the inner and outer rings at the same time and pressed in. If only the inner ring is press-fitted, the force must be pressed into the outer ring by the balls, thus causing scars on the raceway surface.

5. When installing a bearing with a large margin on the shaft, the method of heating the bearing to 80-90 degrees in clean oil to expand the inner diameter is widely used. The hardness of the bearing may be reduced due to overheating, so it must not exceed 100 degrees. At this time, the bearing must be suspended by steel wire, or placed on the wire guide or support plate, not on the bottom of the groove. When the bearing reaches the desired temperature (below 100 degrees), it should be taken out of the groove immediately and put into the shaft quickly. The bearing will shrink as the temperature drops, and sometimes there will be a gap between the shoulder and the end face of the bearing. Use a tool to compress the bearing in the axial direction.

We often read the manual because of a new product, so as to know how to operate and use it and what to pay attention to. This oil-free bearing installation instruction is equivalent to a part of the oil-free bearing product manual, and we also need to understand it, so as to better use and protect the oil-free bearing. And our neglect may damage the bearing and affect the service life of the bearing.

Bushing Assembly Instructions

How to repair and install oil-free sliding bearings? What should you pay attention to when installing? The oil-free sliding bearing is stable, reliable, and quiet in operation. In addition, the oil film has a certain vibration absorption capacity.

Low-cost solution and easy to assemble

bushing installation, the most commonly used method for fitting the bushing is to press them into the housing.

Maintenance Free Operation – Self-lubricating bearings solve the problem of lubrication operation and lubrication devices, which also helps reduce bearing maintenance costs.

Oil-free plain bearing installation

The main technical requirements of oil-free plain bearing assembly are to obtain a reasonable clearance between the journal and the bearing, to ensure good contact between the journal and the bearing, and sufficient lubrication of the copper sleeve so that the journal rotates smoothly and reliably in the bearing. Assembly of oil-free integral plain bearing:

- before assembly, deburr the bearing sleeve and bearing seat hole, clean the dry oil-free bearing and apply lubricating oil to the bearing seat hole.

- according to the size of the shaft sleeve and the interference amount during the fit, the shaft sleeve shall be put into the hole of the bearing seat by knocking or pressing, and shall be fixed.

- the size and shape change easily after the bearing sleeve is pressed into the bearing seat hole, and the inner hole should be trimmed and inspected by means of hinging or scraping of the self-lubricating bearing, so as to ensure a good clearance cooperation between the journal and the bearing sleeve.

Oil-free plain bearing maintenance

The damage forms of sliding bearing include wear, burning, spalling and crack on working surface.The main reason for these defects is that the oil film is damaged for some reason, resulting in direct friction between the journal and the bearing surface.For the defects of different bearing forms, the repair methods adopted are also different.

- for the repair of integral sliding bearing, replacement of shaft sleeve is generally adopted.

- slight wear of split sliding bearing can be handled by adjusting shim and repairing and scraping again.

- internal column and external cone sliding bearing, if there is no serious abrasion on the working surface, the clearance can be adjusted by means of nuts only for precision dressing; When there is a serious scratch on the working surface, the spindle should be removed and the bearing scraped again to restore its fitting precision. When the allowance is not adjusted, the spraying method can be used to increase the diameter of the outer cone of the bearing or to remove the small end of the bearing part of the cone surface, lengthen the thread length to increase the adjustment range and other methods. When the bearing deformation, wear serious, it must be replaced.

- for the multi-tile sliding bearing, when there is a slight scratch on the working surface, the inner surface of the bearing can be polished and repaired by grinding. When the working surface is badly burned or worn by the shaft, the inner surface of the bearing can be repaired by scraping.

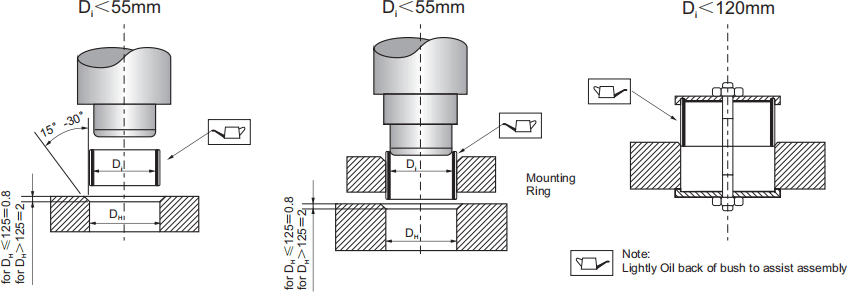

Cylindrical bushes Sliding Bearing Bushing Installation

Self-lubricating bushes Assembly instructions

- Using a chuck

(Hardened carbon steel, polished finish, 60RC surface hardness)

tolerance Ø m6

Mount the bushing using a press ensuring the correct diameter

the mandrel is used so that:

– the bushing is inserted correctly to ensure correct seating

– hole tolerances are still correct after assembly

- Force insertion

– The values are provided assuming that the tolerances are the following;

spindle m6, H7 bore with Ra≤3.2 and considered

be rigid *: 100daN / cm2

(surface equivalent to

Øcm from the outside of the bush)

- Bush before assembly

– Ø interior –Ø1 cylindrical bush F7

(F8 pour Ø1 >50mm)

– Ø interior –Ø1 flanged bush F8

– Ø interior –Ø2 cylindrical bush s7

(S8 pour Ø2 >50mm)

– Ø interior –Ø2 flanged bush s8

The world’s most experienced self-lubricating bearings, bushings, washers and slide plates.

We generally supply all peripheral parts necessary to complete a bearing assembly, including bearing systems, structural components, coupling pins, housings, and any other special requirements. The combination of our metallurgical expertise with an in-house foundry and state-of-the-art welding capabilities facilitates the production of even the largest assembly parts.

It is recommended that complete bearing sets (including pins, shafts, and all related steel components) be designed and manufactured by Lubricate. This approach ensures perfect fit of system components, fast and efficient installation and superior bearing performance.

Our Bushing Assembly – Installation and maintenance

Ready To Place Your Order?

Accredited and Focused on Quality

With a variety of processes at your disposal, such as CNC machining, sheet cutting, and injection molding, we stands as your comprehensive solution for custom manufacturing.

Our High Volume Production Service Provides Dedicated Assistance For Custom Manufacturing Endeavors, Accommodating Projects Of Any Complexity And Scale.

▪ Metal Bearing Production Solutions

Your comprehensive answer for production, our team stands as the ideal choice for your manufacturing requirements.

▪ self-lubricating Bearings Solutions

With our technical specialists, the convenience of our secure quotation platform, and extensive global manufacturing capabilities, we are equipped to meet your needs.

Produce custom components as needed

We’re Your Partner From Prototyping to Production and Beyond

We provide a variety of services to assist you in creating functional prototypes and transitioning to production components. Manufacture custom parts as needed, utilizing various materials for self-lubricating bearings. Reach out to us to benefit from our expert applications engineering team’s production capabilities.

Product Quality Index

Energy Generation

Ready to get started on your custom self-lubricating bearing quote?

Breathtaking design for home living.

The variety of materials, cost-effective custom manufacturing per unit, and rapid production pace make it an excellent choice for prototyping.

Nam aliquet ante porta, gravida elit interdum, luctus porta sapien justo, at fringilla felis suscipit vestibulum.