providing factory services of superior quality with focus on efficiency.

01.

Providing Quotes for Custom Parts and Large-Scale Production Orders

02.

Satisfaction guaranteed

03.

Ensuring timely delivery

04.

Revolutionize How You Produce Custom Components

We Stand by Your Side from Initial Prototyping through to Production and Further.

C86300 Manganese Bronze

C86300 Manganese Bronze Bearing Continuous Cast Bronze Bearing & Bushing

Manganese Bronze Alloys: Alloy with copper as matrix element and manganese as main alloying element.

Manganese bronzes are modifications of Muntz type metal alloys (60% copper 40% zinc brass) containing small additions of manganese

Manganese Bronze – Copper Cast Alloy UNS C86300 is an alloy that is mainly composed of copper, zinc and aluminum. The manganese present in UNS C86300 gives the alloy a chocolate brown color. UNS C86300 copper casting alloy is used in architecture because of its durability.

Tough and corrosion-resistant, C86300 (SAE 430B) Manganese Bronze Bushing is ideal for high load, low-speed applications that require a combination of outstanding wear characteristics and high bearing strength. Despite its strength characteristics, however, this manganese bronze alloy is not heat-treatable, needs reliable lubrication, and should be used in conjunction with hardened shafts. The lead in the alloy’s makeup improves machinability without materially affecting its mechanical properties.

C86300 bronze properties

Chemical Composition:

| Cu%1 | Pb% | Sn% | Zn% | Fe% | Ni%1,2 | Al% | Mn% | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

|

Chemical Composition according to ASTM B505/B505M-18

|

|||||||||||

| 60.00- 66.00 |

0.20 |

0.20 |

22.00- 28.00 |

2.00- 4.00 |

1.00 |

5.00- 7.50 |

2.50- 5.00 |

||||

Bronze Bushing Material – C86300 Manganese Bronze Parts

Wear Characteristics And High Bearing Strength

C86300 manganese bronze is known for its high strength and hardness, the use of manganese as an alloying agent, and the high zinc content. In addition to its excellent mechanical properties, the C86300 manganese also has good corrosion resistance.

C86300 Manganese Bronze (SAE 430B) is a high strength alloy used as bushings, bearings, gears, gibs, screw nuts, bridge pins, valve stems and hydraulic cylinder parts.

C86300 manganese bronze bearing applications require reliable lubrication. Besides excellent mechanical qualities, these alloys have good corrosion resistance.

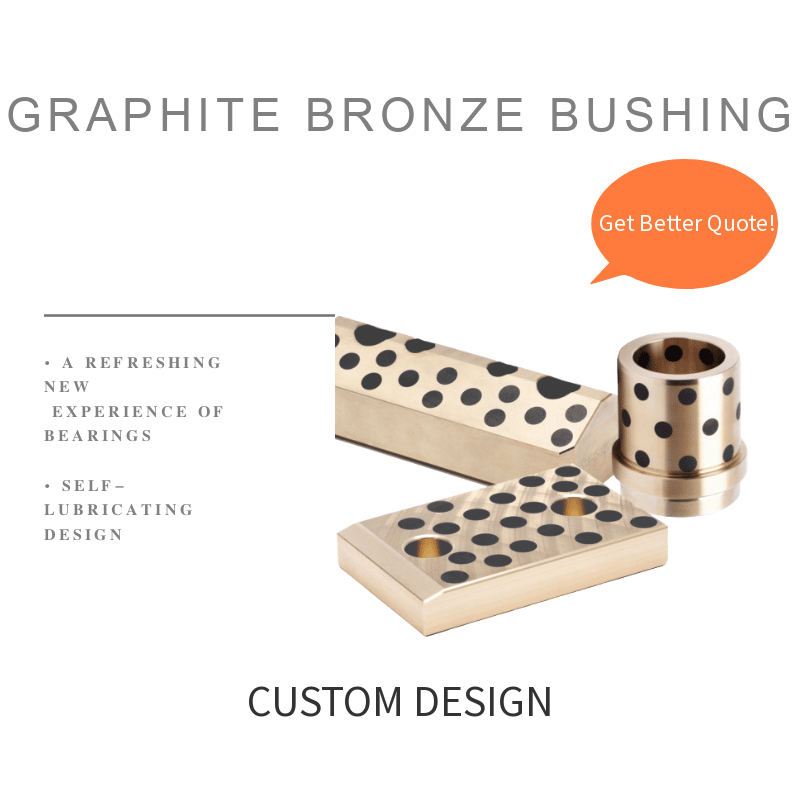

Graphite Plugs Manganese Bronze Bushing Metric & Inch Size

Manganese bronze bearings can operate at high speeds under heavy loads, but require high shaft hardness and nonabrasive operating conditions.

Applications: Industrial – Selecting Bronze Bearing Materials – Manganese Bronze

Manganese bronze is used for applications that require extremely high strength and excellent corrosion resistance.

Manganese bronzes are modifications of Muntz metal alloys (60% copper 40% zinc brass) containing small additions of manganese, iron and aluminum, in addition to lead for lubrication, anti-seizing and embeddibility. Like aluminum bronzes, they combine very high strength with excellent corrosion resistance. Bronze manganese bearings can operate at high speeds under heavy loads, but require high shaft hardness and non-abrasive operating conditions.

Stronger. By Design.

High Tensile (C86300) Manganese Bronze

Manufacturer and supplier of self-lubricating bronze bearing in manganese bronze material

Standard-stocked bronze bearing

Machined Manganese Bronze Bushings

- Customizable design for Extra Heavy Loads

- Highly resistant to deformation

- High Wear-resistant

- Corrosion-resistant

- Low friction coefficient

- Includes Grease or Oil Grooves

The range of bushing products regularly include bearings, flanged and half bushes, wear plates, and many other castings for general engineering

Why choose this manganese bronze material?

- Tensile strengths range from 60,000 psi to 110,000 psi and are readily available depending on the composition of the alloy chosen.

- Special care should be taken when using these alloys as bearings as manganese bronze and steel do not wear well together. Wear is rapid and a seizure can occur with high load and speed. Alignment must be precise and positive lubrication is essential.

Continuous Cast Bronze Parts

The continuous cast process begins with molten bronze being poured through carbon graphite die. The die is surrounded by a cooling jacket, through which water flows to chill and solidify the cast tube, bar, or shape. As the bronze exits the die by gravity, the casting solidifies and is pulled out slowly by rolls or pinch rolls. The rapid cooling process reduces the grain size and as the casting exits from the lower section of the bar machine, a homogeneous microstructure is obtained. With the continuous cast method, a minimum stock allowance can be controlled, reducing the amount of machining necessary to produce a finished part.

Bronze copper sleeve

Bronze copper sleeve, copper-sleeve suppliers, flanging copper sleeve, specializing in the production of flanging copper sleeve, product models are complete, many customers can choose according to the customer situation, support online consultation, free access, can be customized, fast delivery, reliable quality,

Accredited and Focused on Quality

With a variety of processes at your disposal, such as CNC machining, sheet cutting, and injection molding, we stands as your comprehensive solution for custom manufacturing.

Our High Volume Production Service Provides Dedicated Assistance For Custom Manufacturing Endeavors, Accommodating Projects Of Any Complexity And Scale.

▪ Metal Bearing Production Solutions

Your comprehensive answer for production, our team stands as the ideal choice for your manufacturing requirements.

▪ self-lubricating Bearings Solutions

With our technical specialists, the convenience of our secure quotation platform, and extensive global manufacturing capabilities, we are equipped to meet your needs.

Produce custom components as needed

We’re Your Partner From Prototyping to Production and Beyond

We provide a variety of services to assist you in creating functional prototypes and transitioning to production components. Manufacture custom parts as needed, utilizing various materials for self-lubricating bearings. Reach out to us to benefit from our expert applications engineering team’s production capabilities.

Product Quality Index

Energy Generation

Ready to get started on your custom self-lubricating bearing quote?

Breathtaking design for home living.

The variety of materials, cost-effective custom manufacturing per unit, and rapid production pace make it an excellent choice for prototyping.

Nam aliquet ante porta, gravida elit interdum, luctus porta sapien justo, at fringilla felis suscipit vestibulum.