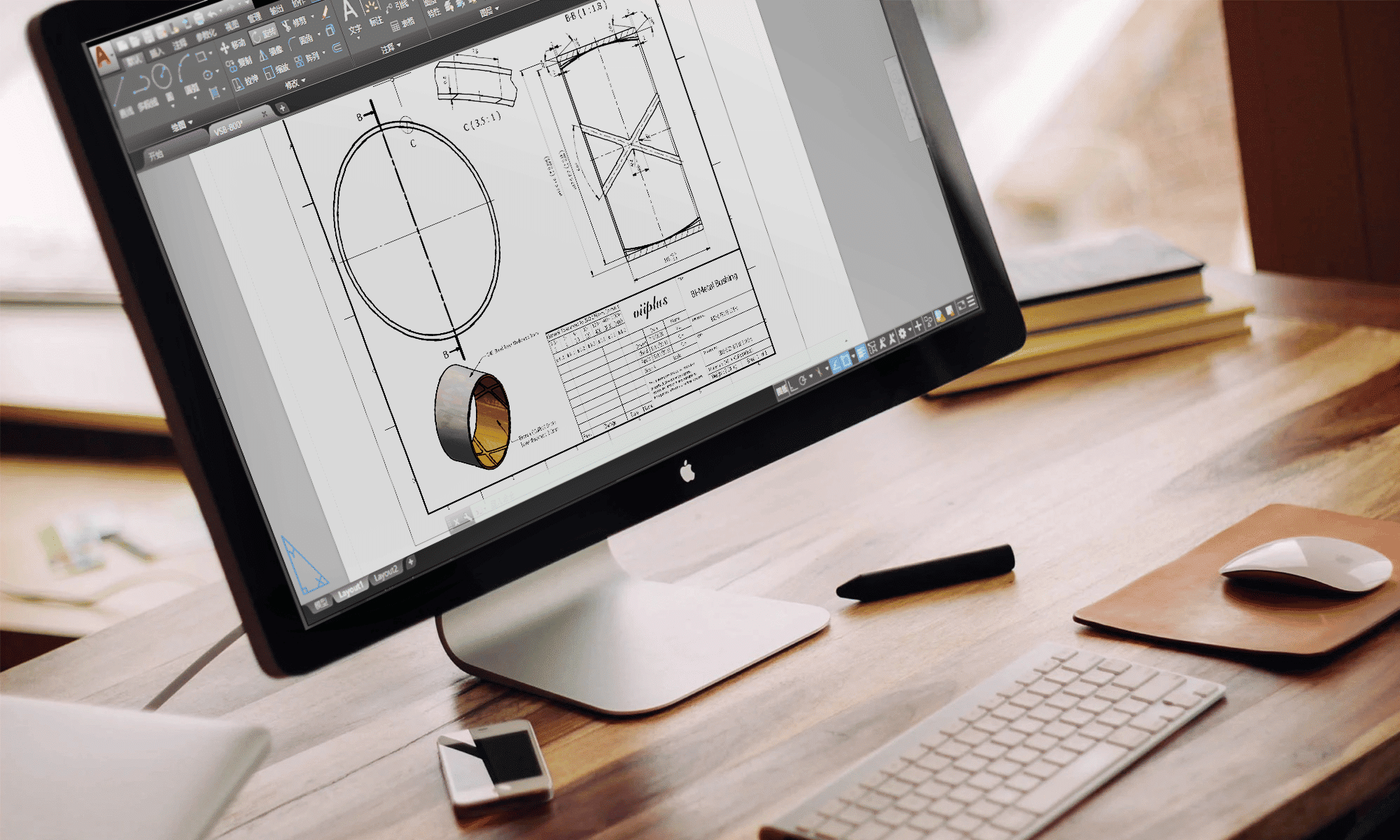

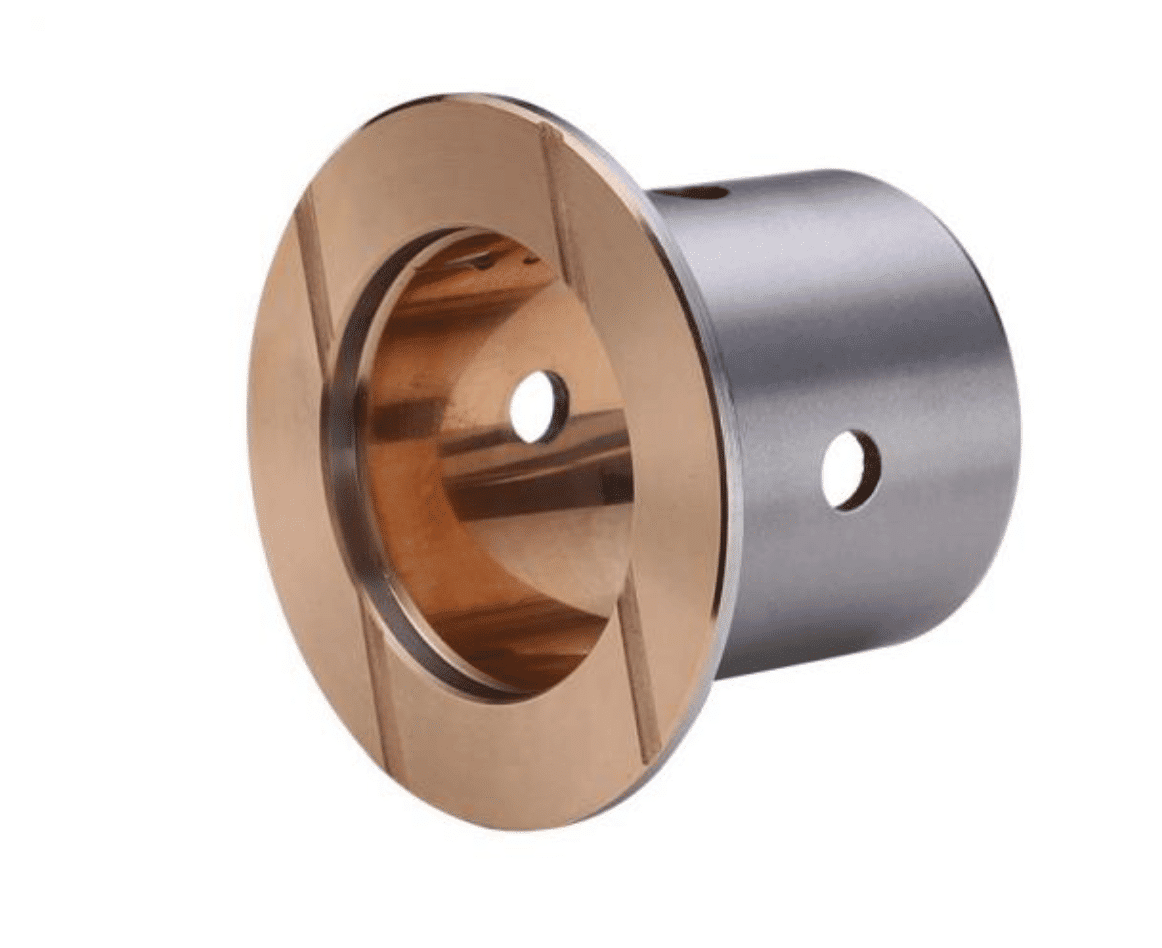

Reliable & Safe Bimetal Bearings Supplier, OEM Service Auto Con Rod Bearing Bushings Bimetal bushing

Check out bimetal selection for the very best in unique or custom bimetal bushings size and bimetal bearings material from bronzelube.com. Bimetal Bearing – Factory Direct & Fast Shipping On-Site Engineering: Experienced Manufacturer & Supplier in China. Steel+CuPb10Sn10 Guaranteed Top Quality & Service. Quality Bimetal Bearing Supplier & Manufacturer in China, Contact Now! Advanced Technology. Wholesale Price.

Reliable, light and excellent bimetal bearing solutions

Various Type And Sizes, Material: Steel + Alloy CuPb10Sn10、CuPb6Sn6Zn3、CuPb24Sn4、CuPb30、AlSn20Cu、CuSn8Ni, with groove type, self-lubricating holes. We stand behind the quality of our bimetal bushing products, Top Deals at Factory Price! Place Orders Online From Us. Logistics Service! Interested in bi-metal bearings product, Get the best quote!

In addition to metric products or non-standard bearings, friction welding bimetal bushing, bi metal bushes, steel bushings supplier.

taxation planning

Eiusmod tempor incididunt ipsum ut labore dolore magna aliqua. Ut enim minim veniam duisy ipsum sed quis.

Expensive price, material-designed, steel bushings for sale

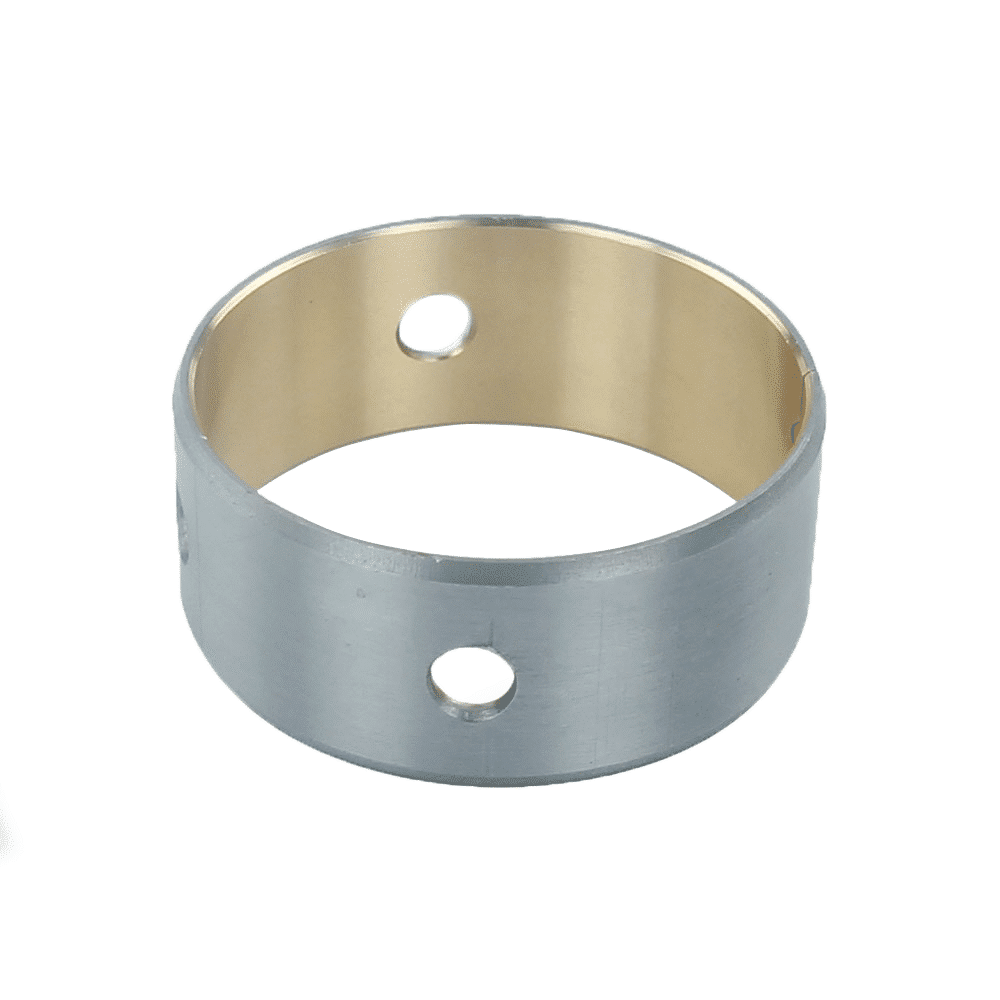

Bimetal Bearing Completed Reliably From Production To Ship. Get Top Quality From China Bimetal Bushings Supplier Without a Premium Price. Customization Bimetal Bearings Alloy Material Available! Quality Bimetal Bushings Supplier & Manufacturer in China, Contact Now! Advanced Technology。Quality Assurance! Wholesale Price, Factory Direct! Bimetal bushes are produced from Bimetal strips with Sintered Copper-Lead Bronze lining and Steel as backing up material. Bimetal Bearing Bushes CuPb6Sn6Zn3 or CuPb10Sn10 Alloy.

Bimetal Bushings – Excellent Supplier from China.

Sliding Bearing: Steel/Bronze Composite with Lubrication Pockets, Low-Maintenance, Material: Copper-plated/Tin-plated Steel, Composition: CuPb10Sn10, Type: Cylindrical Bushing

Metal & Bimetal Bushings: Find here Bimetal Bushes manufacturers & suppliers from China. Friction welding bimetal bushing metric flange bushings.

- Steel Backing and Leaded Bronze Overlay

- Steel + CuPb10Sn10 alloy bimetal bushing

- Steel + CuPb6Sn6Zn3 with indents

- Normal Metric Bimetal Bushing ISO3547 (DIN1494)

- Bimetal Series Metric Flange Bushing

Bimetal Bearing Groove, Metal Bushings by Size

Beautifully crafted leather products.

Bimetal Production Bearing Always tested. Always proven. Global website www.bronzelube.com, Bimetal Bearing Bushes Supplier, Bimetal Bearing Bushes Supplier. Bimetallic self-lubricating bearing uses high quality low-carbon steel plate as backing, sintered porous bronze as its liner, suitable for rotatory oscillating, reciprocating movements in the conditions of high load, low speed, low friction, wear resistance, a long working life span on preventing the mating parts from holding-on. The bronze layer surface can be machined with various of grooves, oil pockets in terms of different working conditions. The product is widely used in mining machinery, automobile, building machinery, agriculture equipment, rolling steel industry etc.

Bi-Metal Bushings Manufacturers and Suppliers Better Price

Metal and Bimetal Bearings

Wrapped composite sliding bearing, Copper-plated or tin-plated steel backed bronze, DIN 1494 / ISO 3547, Maintenance-free, With lubrication pockets

Wrapped Composite Sliding Bearing with Steel/Bronze Construction, Lubrication Pockets, and Low Friction

A wrapped composite sliding bearing refers to a type of bearing that consists of layers of different materials wrapped around a cylindrical core. In the case of steel/bronze construction, the bearing typically comprises an inner steel shell and an outer layer made of bronze.

This combination of steel and bronze offers several advantages for sliding bearing applications. The steel provides high strength and rigidity, while the bronze layer contributes to excellent wear resistance and low friction properties. This construction ensures the bearing can withstand heavy loads and provide reliable performance in demanding environments.

One notable feature of this type of bearing is the inclusion of lubrication pockets. Lubrication pockets are small indentations or grooves strategically placed within the bearing surface. These pockets serve as reservoirs for lubricant, allowing for effective lubrication and reducing friction between the bearing and the mating surface. The lubrication pockets help to minimize wear and extend the bearing’s lifespan.

Additionally, wrapped composite sliding bearings with steel/bronze construction are designed to have low friction characteristics. The bronze layer provides a self-lubricating property, reducing the need for constant lubrication and maintenance. This feature makes the bearing well-suited for applications where frequent lubrication may be difficult or impractical.

Wrapped composite sliding bearings with steel/bronze construction, lubrication pockets, and low friction properties are widely used in various industries. They find applications in automotive systems, industrial machinery, hydraulic equipment, and more, providing reliable and efficient performance in sliding motion applications.

We are happy to serve you

STRUCTURE AND COMPOSITION

Steel Backing and Leaded Bronze Overlay

Steel + Sliding layer CuPb10Sn10 with indents

Steel copper-plated or tin-plated

Bimetal Bearings is a low-maintenance bushing material. An initial greasing during installation is necessary, after that periodic greasing with oil or grease is mandatory.

Bimetal Plain Bearings to Standard SAE 792 Sliding layer CuPb10Sn10

Bimetal composite bearings with high quality steel backed bushings, the surface of the sinter with low friction properties of copper alloy (CuPb10Sn10 CuPb6Sn6Zn3 CuPb24Sn4, CuPb30, AlSn20Cu, CuSn8Ni) as wear-resisting sliding layer of bearing.

Copper-Plated/Tin-Plated Steel for Sliding Bearings: Characteristics, Composition (CuPb10Sn10), and Applications

Copper-plated/tin-plated steel is a material commonly used in the manufacturing of sliding bearings. It possesses several characteristics and properties that make it suitable for this application.

The composition of copper-plated/tin-plated steel in sliding bearings is often CuPb10Sn10. This composition refers to a blend of copper (Cu), lead (Pb), and tin (Sn) in specific proportions.

CuPb10Sn10 offers various advantages in the production of high-performance sliding bearings. Its composition provides excellent wear resistance, low friction coefficients, and good load-carrying capacity. These properties make it ideal for applications where smooth and reliable sliding motion is required.

Sliding bearings using copper-plated/tin-plated steel, such as cylindrical bushings, have a wide range of applications. They are commonly used in machinery and equipment where rotational or sliding movements occur, such as automotive engines, industrial machinery, and hydraulic systems. Cylindrical bushings play a crucial role in sliding bearing systems by providing support, reducing friction, and facilitating smooth motion.

When designing cylindrical bushings for sliding bearing applications, certain considerations are essential. Factors like load capacity, operating temperature, lubrication requirements, and dimensional tolerances must be taken into account. Proper design ensures optimal performance and longevity of the sliding bearing system.

In summary, copper-plated/tin-plated steel, particularly CuPb10Sn10, is a versatile material used in the manufacturing of sliding bearings. It offers desirable characteristics, including wear resistance and low friction coefficients, making it suitable for various applications. Cylindrical bushings, a type of sliding bearing, play a vital role in machinery and require careful design considerations to ensure optimal performance.

MATERIALS

Support material

Steel copper-plated or tin-plated

Sliding layer: CuPb10Sn10

STRUCTURE AND COMPOSITION

Steel Backed and Bronze Layer Steel + CuPb10Sn10 with indents

Sliding layer with lubrication indents

CuPb10Sn10 with

composition approx.:

Cu 80 %

Pb 10 %

Sn 10 %

Steel backing

Material Characteristics

| Data | Bimetal Plain Bearings to Standard SAE 792 | Bimetal strip from tin-aluminium alloy |

| Bimetal Plain Bearings Structure | ||

| Steel + CuPb10Sn10 | Steel + AlSn20Cu | |

| Corresponding Code | SAE-792(SAE797). JIS-LBC3. |

SAE-783. JIS-AJL. |

| Clevite F100. GGB-SY. Daido L10. Federal Mogul HF-2F.Glyco 66. |

Federal Mogul TR-20. Glyco 74. |

|

| Max Load Capacity P | 150N/mm2 | 100N/mm2 |

| Grease Lubrication | ||

| Max Speed V | 2.5m/s | |

| Maximum PV Value | 2.8N/mm2 · m/s | |

| Coefficient of friction u | 0.05~0.15 | |

| (Oil)Lubrication | ||

| Max Speed V | 10m/s | 25m/s |

| Maximum PV Value | 10N/mm2 · m/s | 6N/mm2 · m/s |

| 0.05~0.12 | 0.06~0.17 | |

| Max Working Temperature | ||

| Grease Lubrication | 150℃ | 150℃ |

| Lubrication | 250℃ | 250℃ |

| Alloy Hardness | 60~100HB | 30~40HB |

Bimetallic Bearings Bushings Material Characteristics

- Lubrication Design

- Split Gap Design

- Oil Hole Design

- Application

Bi-metallic bushing is formed from steel strips with sliding bronze alloy lining material. The alloy lined surface can be machined oil grooves, holes, formed Indentations etc according to different application. It is suitable for high load, lower speed oscillation & rotation movement.

Bimetal bearing bushing buckle oil hole design

In the bimetal bearing bushings design, if the following oil hole is used, the bimetal bearing bushings product can be fully lubricated in use. If there is no special requirement, this oil hole design is also applicable.

| Oil Hole is necessary to design if bimetal bearings have lubricated sufficiently; the following oil hole design is recommended, which is also suitable for bimetal bearings series without special requirements. | |||||

| Bushing O.D. (D) | Φ14>D ≤ 22 | Φ22>D ≤ 40 | Φ40>D ≤ 50 | Φ50>D ≤ 100 | Φ100>D ≤ 180 |

| Oil Hole Diameter (mm) | 3 | 4 | 5 | 6 | 7 |

| Oil hole location should keep away from the split gap & loading area, and in favor of oil-taking. | |||||

Bimetal bearing oil holes should be located away from joints and bearing areas and should facilitate oil intake.

Bimetal Bearings Application

THE BIMETAL BEARINGS SOLUTION PROVIDER FOR INDUSTRIAL

PROGRESS, REGARDLESS OF SHAPE OR MATERIAL

Bimetal bearings will most notably benefit transmissions and truck brakes as well as agricultural, mechanical handling and lifting applications. Track rollers, construction machines, crane construction (impact loading)

It is one of the solid enterprises in China specializing in the production of self-lubricating bearings, bimetal bearing bushings, plain bearings, composite bearings, oil-free bearings, dry bearings and maintenance-free bearings.

To determine which bimetal bearings bushings product is best suited to your application, Select your market.

| bi-metallic bushing CuPb10Sn10 |

It has high fatigue strength, high bearing capacity, high impact resistance and wear resistance, suitable for medium to high speed applications such as gear box, rocker sleeve, main pin, transmission device, common sleeve and so on |

| bi-metallic bushing CuPb24Sn4 |

It has high anti-fatigue strength, bearing capacity and anti-impact force, and good surface sliding performance. It is suitable for medium speed and medium load. When the surface is coated with soft alloy, it can be used for high-speed internal combustion engine spindle sleeve and connecting rod sleeve. |

| bi-metallic bushing CuPb30 |

Has very good sliding performance, good bite resistance. It is a kind of special material, the surface is not suitable for processing oil groove and oil hole, generally need to be plated with soft alloy. It is suitable for high speed, medium and low load internal combustion engine spindle sleeve and connecting rod shaft sleeve. It can also be used for hydraulic pump, automatic gear box, etc. |

| bi-metallic bushing AlSn20Cu |

With moderate fatigue strength and bearing capacity, good sliding performance, the product is suitable for high-speed low-load internal combustion engine bearing bush, air compressor, refrigerator, hypoid gear box, hydraulic pump, gear box, etc. |

BIMETAL BEARING SOLUTIONS FOR LUBRICATED APPLICATIONS

Bimetal bearings split type is available as a standard range of cylindrical wrapped bushes and thrust washers in metric sizes with or without oil holes.

Dimensions and tolerances follow ISO 3547 and standard specifications.

Non standard parts, bimetal bearings bushing material strip and special forms to order.

Always tested. Always proven.

Bimetal Bearings, Flange Bimetal Bushing, Long-lasting, self-lubricating

Bimetal Plain Bearings to Standard SAE 792

Bimetal Bush Bearing Size Chart

| PM2025SY | 20 | 23 | 25 | H7 | h8 | 20.161 | 20.02 | 0.194 | 0.02 | 4 |

| PM2030SY | 20 | 23 | 30 | H7 | h8 | 20.161 | 20.02 | 0.194 | 0.02 | 4 |

| PM2215SY | 22 | 25 | 15 | H7 | h8 | 22.161 | 22.02 | 0.194 | 0.02 | 6 |

| PM2220SY | 22 | 25 | 20 | H7 | h8 | 22.161 | 22.02 | 0.194 | 0.02 | 6 |

| PM2225SY | 22 | 25 | 25 | H7 | h8 | 22.161 | 22.02 | 0.194 | 0.02 | 6 |

| PM2230SY | 22 | 25 | 30 | H7 | h8 | 22.161 | 22.02 | 0.194 | 0.02 | 6 |

| PM2515SY | 25 | 28 | 15 | H7 | h8 | 25.161 | 25.02 | 0.194 | 0.02 | 6 |

| PM2520SY | 25 | 28 | 20 | H7 | h8 | 25.161 | 25.02 | 0.194 | 0.02 | 6 |

| PM2525SY | 25 | 28 | 25 | H7 | h8 | 25.161 | 25.02 | 0.194 | 0.02 | 6 |

| PM2530SY | 25 | 28 | 30 | H7 | h8 | 25.161 | 25.02 | 0.194 | 0.02 | 6 |

| PM2815SY | 28 | 32 | 15 | H7 | h8 | 28.185 | 28.04 | 0.218 | 0.04 | 6 |

| PM2820SY | 28 | 32 | 20 | H7 | h8 | 28.185 | 28.04 | 0.218 | 0.04 | 6 |

| PM2825SY | 28 | 32 | 25 | H7 | h8 | 28.185 | 28.04 | 0.218 | 0.04 | 6 |

| PM2830SY | 28 | 32 | 30 | H7 | h8 | 28.185 | 28.04 | 0.218 | 0.04 | 6 |

| PM3015SY | 30 | 34 | 15 | H7 | h8 | 30.185 | 30.04 | 0.218 | 0.04 | 6 |

| PM3020SY | 30 | 34 | 20 | H7 | h8 | 30.185 | 30.04 | 0.218 | 0.04 | 6 |

| PM3025SY | 30 | 34 | 25 | H7 | h8 | 30.185 | 30.04 | 0.218 | 0.04 | 6 |

| PM3030SY | 30 | 34 | 30 | H7 | h8 | 30.185 | 30.04 | 0.218 | 0.04 | 6 |

| PM3040SY | 30 | 34 | 40 | H7 | h8 | 30.185 | 30.04 | 0.218 | 0.04 | 6 |

| PM3230SY | 32 | 36 | 30 | H7 | h8 | 32.185 | 32.04 | 0.224 | 0.04 | 6 |

| PM3240SY | 32 | 36 | 40 | H7 | h8 | 32.185 | 32.04 | 0.224 | 0.04 | 6 |

| PM3515SY | 35 | 39 | 15 | H7 | h8 | 35.185 | 35.04 | 0.224 | 0.04 | 6 |

| PM3520SY | 35 | 39 | 20 | H7 | h8 | 35.185 | 35.04 | 0.224 | 0.04 | 6 |

| PM3525SY | 35 | 39 | 25 | H7 | h8 | 35.185 | 35.04 | 0.224 | 0.04 | 6 |

| PM3530SY | 35 | 39 | 30 | H7 | h8 | 35.185 | 35.04 | 0.224 | 0.04 | 6 |

| PM3535SY | 35 | 39 | 35 | H7 | h8 | 35.185 | 35.04 | 0.224 | 0.04 | 6 |

| PM3540SY | 35 | 39 | 40 | H7 | h8 | 35.185 | 35.04 | 0.224 | 0.04 | 6 |

| PM3545SY | 35 | 39 | 45 | H7 | h8 | 35.185 | 35.04 | 0.224 | 0.04 | 6 |

| PM3550SY | 35 | 39 | 50 | H7 | h8 | 35.185 | 35.04 | 0.224 | 0.04 | 6 |

| PM4020SY | 40 | 44 | 20 | H7 | h8 | 40.185 | 40.04 | 0.224 | 0.04 | 8 |

| PM4030SY | 40 | 44 | 30 | H7 | h8 | 40.185 | 40.04 | 0.224 | 0.04 | 8 |

| PM4040SY | 40 | 44 | 40 | H7 | h8 | 40.185 | 40.04 | 0.224 | 0.04 | 8 |

| PM4050SY | 40 | 44 | 50 | H7 | h8 | 40.185 | 40.04 | 0.224 | 0.04 | 8 |

| PM4060SY | 40 | 44 | 60 | H7 | h8 | 40.185 | 40.04 | 0.224 | 0.04 | 8 |

| PM4530SY | 45 | 50 | 30 | H7 | h8 | 45.225 | 45.08 | 0.264 | 0.08 | 8 |

| PM4540SY | 45 | 50 | 40 | H7 | h8 | 45.225 | 45.08 | 0.264 | 0.08 | 8 |

| PM4550SY | 45 | 50 | 50 | H7 | h8 | 45.225 | 45.08 | 0.264 | 0.08 | 8 |

| PM4560SY | 45 | 50 | 60 | H7 | h8 | 45.225 | 45.08 | 0.264 | 0.08 | 8 |

| PM5030SY | 50 | 55 | 30 | H7 | h8 | 50.23 | 50.08 | 0.269 | 0.08 | 8 |

| PM5040SY | 50 | 55 | 40 | H7 | h8 | 50.23 | 50.08 | 0.269 | 0.08 | 8 |

| PM5050SY | 50 | 55 | 50 | H7 | h8 | 50.23 | 50.08 | 0.269 | 0.08 | 8 |

| PM5060SY | 50 | 55 | 60 | H7 | h8 | 50.23 | 50.08 | 0.269 | 0.08 | 8 |

| PM5535SY | 55 | 60 | 35 | H7 | h8 | 55.23 | 55.08 | 0.276 | 0.08 | 8 |

| PM5540SY | 55 | 60 | 40 | H7 | h8 | 55.23 | 55.08 | 0.276 | 0.08 | 8 |

| PM5555SY | 55 | 60 | 55 | H7 | h8 | 55.23 | 55.08 | 0.276 | 0.08 | 8 |

| PM5560SY | 55 | 60 | 60 | H7 | h8 | 55.23 | 55.08 | 0.276 | 0.08 | 8 |

| PM6030SY | 60 | 65 | 30 | H7 | h8 | 60.23 | 60.08 | 0.276 | 0.08 | 8 |

| PM6040SY | 60 | 65 | 40 | H7 | h8 | 60.23 | 60.08 | 0.276 | 0.08 | 8 |

| PM6060SY | 60 | 65 | 60 | H7 | h8 | 60.23 | 60.08 | 0.276 | 0.08 | 8 |

| PM6540SY | 65 | 70 | 40 | H7 | h8 | 65.23 | 65.08 | 0.276 | 0.08 | 8 |

| PM6550SY | 65 | 70 | 50 | H7 | h8 | 65.23 | 65.08 | 0.276 | 0.08 | 8 |

| PM6560SY | 65 | 70 | 60 | H7 | h8 | 65.23 | 65.08 | 0.276 | 0.08 | 8 |

| PM6570SY | 65 | 70 | 70 | H7 | h8 | 65.23 | 65.08 | 0.276 | 0.08 | 8 |

| PM7040SY | 70 | 75 | 40 | H7 | h8 | 70.23 | 70.08 | 0.276 | 0.08 | 8 |

| PM7045SY | 70 | 75 | 45 | H7 | h8 | 70.23 | 70.08 | 0.276 | 0.08 | 8 |

| PM7050SY | 70 | 75 | 50 | H7 | h8 | 70.23 | 70.08 | 0.276 | 0.08 | 8 |

| PM7065SY | 70 | 75 | 65 | H7 | h8 | 70.23 | 70.08 | 0.276 | 0.08 | 8 |

| PM7080SY | 70 | 75 | 80 | H7 | h8 | 70.23 | 70.08 | 0.276 | 0.08 | 8 |

| PM7540SY | 75 | 80 | 40 | H7 | h8 | 75.23 | 75.08 | 0.276 | 0.08 | 9.5 |

| PM7560SY | 75 | 80 | 60 | H7 | h8 | 75.23 | 75.08 | 0.276 | 0.08 | 9.5 |

| PM7580SY | 75 | 80 | 80 | H7 | h8 | 75.23 | 75.08 | 0.276 | 0.08 | 9.5 |

| PM8040SY | 80 | 85 | 40 | H7 | h8 | 80.235 | 80.08 | 0.281 | 0.08 | 9.5 |

| PM8060SY | 80 | 85 | 60 | H7 | h8 | 80.235 | 80.08 | 0.281 | 0.08 | 9.5 |

| PM8075SY | 80 | 85 | 75 | H7 | h8 | 80.235 | 80.08 | 0.281 | 0.08 | 9.5 |

| PM8080SY | 80 | 85 | 80 | H7 | h8 | 80.235 | 80.08 | 0.281 | 0.08 | 9.5 |

| PM8560SY | 85 | 90 | 60 | H7 | h8 | 85.235 | 85.08 | 0.289 | 0.08 | 9.5 |

| PM9040SY | 90 | 95 | 40 | H7 | h8 | 90.235 | 90.08 | 0.289 | 0.08 | 9.5 |

| PM9070SY | 90 | 95 | 70 | H7 | h8 | 90.235 | 90.08 | 0.289 | 0.08 | 9.5 |

| PM9090SY | 90 | 95 | 90 | H7 | h8 | 90.235 | 90.08 | 0.289 | 0.08 | 9.5 |

| PM10040SY | 100 | 105 | 40 | H7 | h8 | 100.235 | 100.08 | 0.289 | 0.08 | 9.5 |

| PM10050SY | 100 | 105 | 50 | H7 | h8 | 100.235 | 100.08 | 0.289 | 0.08 | 9.5 |

| PM10060SY | 100 | 105 | 60 | H7 | h8 | 100.235 | 100.08 | 0.289 | 0.08 | 9.5 |

| PM10080SY | 100 | 105 | 80 | H7 | h8 | 100.235 | 100.08 | 0.289 | 0.08 | 9.5 |

| PM10095SY | 100 | 105 | 95 | H7 | h8 | 100.235 | 100.08 | 0.289 | 0.08 | 9.5 |

| PM12050SY | 120 | 125 | 50 | H7 | h8 | 120.24 | 120.08 | 0.294 | 0.08 | 9.5 |

| PM13560SY | 135 | 140 | 60 | H7 | h8 | 120.24 | 135.08 | 0.303 | 0.08 |

Bimetal Plain Bearings Steel + CuPb6Sn6Zn3

Steel + CuPb6Sn6Zn3 bimetal bearing bushings are widely used in industrial applications, particularly in heavy machinery and automotive industries. These bushings are made up of two layers – a steel back and a CuPb6Sn6Zn3 alloy lining. The steel layer provides a strong and durable base for the bushing, while the CuPb6Sn6Zn3 alloy lining offers excellent sliding and wear resistance properties.

The steel layer of the bushing is typically made of high-quality carbon steel or alloy steel, which provides high strength and stiffness. This layer is usually made using a hot rolling process or a powder metallurgy process, which helps to ensure that the steel layer has a consistent thickness and a smooth surface finish. The steel layer also undergoes various heat treatment processes, such as hardening and tempering, to improve its strength and wear resistance properties.

The CuPb6Sn6Zn3 alloy lining layer is made up of a mixture of copper, lead, tin, and zinc, which is melted and cast onto the steel layer using a centrifugal casting process. This layer provides excellent sliding properties due to its high lead content, which helps to reduce friction and wear. The tin and zinc content of the alloy also provides excellent corrosion resistance properties, which helps to protect the bearing from rust and other forms of corrosion.

Steel + CuPb6Sn6Zn3 bimetal bearing bushings have a number of advantages over other types of bearings. Firstly, they offer excellent load-bearing capacity and wear resistance, making them ideal for use in heavy machinery and equipment. They also offer good corrosion resistance, which helps to prolong the life of the bearing and reduce maintenance costs. Additionally, they are relatively easy to manufacture and are cost-effective compared to other types of bearings.

Despite these advantages, steel + CuPb6Sn6Zn3 bimetal bearing bushings do have some limitations. Firstly, they are not suitable for use in high-temperature applications, as the CuPb6Sn6Zn3 alloy lining can melt and degrade at high temperatures. Secondly, they are not suitable for use in applications that require high precision and accuracy, as the CuPb6Sn6Zn3 alloy lining can deform and wear over time.

In conclusion, Steel + CuPb6Sn6Zn3 bimetal bearing bushings are a popular choice for industrial applications due to their excellent load-bearing capacity, wear resistance, and corrosion resistance properties. They are relatively easy to manufacture and cost-effective, making them an ideal choice for heavy machinery and equipment. However, they do have limitations, particularly in high-temperature and high-precision applications, and alternative bearing materials may be more suitable in these situations.

Bimetal Plain Bearings CuPb10Sn10 with indents

Bimetal sleeve bearings made from Steel + CuPb10Sn10 with indents are a popular choice in many industrial applications, particularly in heavy machinery and automotive industries. These bearings consist of two layers – a steel back and a CuPb10Sn10 alloy lining with indents. The steel layer provides a strong and durable base for the bearing, while the CuPb10Sn10 alloy lining with indents offers excellent sliding and wear resistance properties.

The steel layer of the bearing is typically made of high-quality carbon steel or alloy steel, which provides high strength and stiffness. This layer is usually made using a hot rolling process or a powder metallurgy process, which helps to ensure that the steel layer has a consistent thickness and a smooth surface finish. The steel layer also undergoes various heat treatment processes, such as hardening and tempering, to improve its strength and wear resistance properties.

The CuPb10Sn10 alloy lining layer with indents is made up of a mixture of copper, lead, tin, and other trace elements, which is melted and cast onto the steel layer using a centrifugal casting process. The indents on the surface of the lining layer create small pockets of lubricant that help to reduce friction and wear, as well as distribute the lubricant evenly across the surface of the bearing. The tin content of the alloy also provides excellent corrosion resistance properties, which helps to protect the bearing from rust and other forms of corrosion.

Bimetal sleeve bearings made from Steel + CuPb10Sn10 with indents offer a number of advantages over other types of bearings. Firstly, they offer excellent load-bearing capacity and wear resistance, making them ideal for use in heavy machinery and equipment. The indents on the surface of the lining layer also help to distribute lubricant evenly across the surface of the bearing, reducing friction and wear. They also offer good corrosion resistance, which helps to prolong the life of the bearing and reduce maintenance costs. Additionally, they are relatively easy to manufacture and are cost-effective compared to other types of bearings.

Despite these advantages, bimetal sleeve bearings made from Steel + CuPb10Sn10 with indents do have some limitations. Firstly, they are not suitable for use in high-temperature applications, as the CuPb10Sn10 alloy lining can melt and degrade at high temperatures. Secondly, they are not suitable for use in applications that require high precision and accuracy, as the indents on the surface of the lining layer can cause uneven wear over time.

In conclusion, bimetal sleeve bearings made from Steel + CuPb10Sn10 with indents are a popular choice for industrial applications due to their excellent load-bearing capacity, wear resistance, and corrosion resistance properties. The indents on the surface of the lining layer help to distribute lubricant evenly across the surface of the bearing, reducing friction and wear. However, they do have limitations, particularly in high-temperature and high-precision applications, and alternative bearing materials may be more suitable in these situations.

Bimetal Plain Bearings Steel + CuPb24Sn4 alloy

Bimetal sleeve bushings made from Steel + CuPb24Sn4 alloy are a widely used bearing material in various industrial applications, such as heavy machinery, automotive, and construction equipment. These bearings consist of two layers, a steel back and a CuPb24Sn4 alloy lining, which provides excellent wear resistance and anti-seizing properties.

The steel back layer of the bimetal sleeve bushing is typically made of high-quality carbon steel or alloy steel, which provides a strong and durable foundation for the bearing. The steel layer is usually made using a hot rolling or powder metallurgy process, which helps to ensure a consistent thickness and a smooth surface finish. Additionally, the steel layer undergoes various heat treatment processes, such as hardening and tempering, to enhance its strength and wear resistance properties.

The CuPb24Sn4 alloy lining layer is made up of a mixture of copper, lead, tin, and other trace elements, which is melted and cast onto the steel back layer using a centrifugal casting process. The CuPb24Sn4 alloy lining provides excellent wear resistance and anti-seizing properties due to the presence of lead in the alloy composition. The high tin content of the alloy also offers excellent corrosion resistance properties, making the bimetal sleeve bushing ideal for use in harsh environments.

Bimetal sleeve bushings made from Steel + CuPb24Sn4 alloy offer several advantages over other types of bearings. Firstly, they offer excellent load-bearing capacity and wear resistance, making them ideal for use in heavy machinery and equipment. Additionally, the CuPb24Sn4 alloy lining provides excellent anti-seizing properties, which helps to prevent the bearing from seizing due to high friction and pressure. Secondly, they offer good corrosion resistance, which helps to prolong the life of the bearing and reduce maintenance costs.

Despite these advantages, bimetal sleeve bushings made from Steel + CuPb24Sn4 alloy do have some limitations. Firstly, they are not suitable for use in high-temperature applications, as the CuPb24Sn4 alloy lining can melt and degrade at high temperatures. Secondly, they are not suitable for use in applications that require high precision and accuracy, as the bimetal sleeve bushing may experience uneven wear over time.

Bimetal sleeve bushings made from Steel + CuPb24Sn4 alloy are a widely used bearing material in various industrial applications, offering excellent load-bearing capacity, wear resistance, and anti-seizing properties. The alloy composition of the lining layer provides good corrosion resistance properties, making it suitable for use in harsh environments. However, it is important to consider the limitations of this bearing material, particularly in high-temperature and high-precision applications, and alternative bearing materials may be more suitable in these situations.

Bimetal Plain Bearings Steel + CuPb30 alloy

Bimetal bearing bushings made from Steel + CuPb30 alloy are a popular choice for many industrial applications. These bearings consist of two layers, a steel back layer and a CuPb30 alloy lining layer, which provides excellent wear resistance and anti-seizing properties.

The steel back layer is typically made of high-quality carbon steel or alloy steel, which provides a strong and durable foundation for the bearing. The steel layer is usually made using a hot rolling or powder metallurgy process, which helps to ensure a consistent thickness and a smooth surface finish. Additionally, the steel layer undergoes various heat treatment processes, such as hardening and tempering, to enhance its strength and wear resistance properties.

The CuPb30 alloy lining layer is made up of a mixture of copper, lead, and other trace elements, which is melted and cast onto the steel back layer using a centrifugal casting process. The CuPb30 alloy lining provides excellent wear resistance and anti-seizing properties due to the presence of lead in the alloy composition. The high copper content of the alloy also offers excellent thermal conductivity, making the bimetal bearing bushing ideal for use in high-temperature applications.

Bimetal bearing bushings made from Steel + CuPb30 alloy offer several advantages over other types of bearings. Firstly, they offer excellent load-bearing capacity and wear resistance, making them ideal for use in heavy machinery and equipment. Additionally, the CuPb30 alloy lining provides excellent anti-seizing properties, which helps to prevent the bearing from seizing due to high friction and pressure. Secondly, they offer good thermal conductivity, which helps to dissipate heat and maintain stable operating temperatures.

Despite these advantages, bimetal bearing bushings made from Steel + CuPb30 alloy do have some limitations. Firstly, they are not suitable for use in highly corrosive environments, as the CuPb30 alloy lining can corrode over time. Secondly, they are not suitable for use in applications that require high precision and accuracy, as the bimetal bearing bushing may experience uneven wear over time.

In conclusion, bimetal bearing bushings made from Steel + CuPb30 alloy are a popular choice for many industrial applications, offering excellent load-bearing capacity, wear resistance, and anti-seizing properties. The alloy composition of the lining layer provides good thermal conductivity properties, making it suitable for use in high-temperature applications. However, it is important to consider the limitations of this bearing material, particularly in highly corrosive and high-precision applications, and alternative bearing materials may be more suitable in these situations.

Bimetal Bushing Advantage

Beautifully crafted leather products.

High Quality Bimetal Bearings Benefits:

- Bimetal Bearing Maintenance-free

- Bimetal Sleeve Bushing Lightweight

- Bimetal Flange Bushing Self-lubricating components

- Bimetal Bearing Type Resistant to dirt, dust, and corrosion

- Free on-site consulting and design

- System construction kit

Bimetal Bearing Exporter, Bimetal Bushing Expert, Bimetal Bearing Supplier. Plain bearings from bronzelube.com extend service life & reduce costs by up to 50%.

BIMETALLIC BEARINGS APPLICATION

Bimetal Flanged Bushing for Heavy-Duty Trucks, Best Performance Bimetal Bushing for Excavator! Auto Parts Engine Bimetal Connecting Rod Bushing, bimetal bush king pin bush connecting rod bushings plain bearing, welding flange type bushes. Get Latest Price!