A Guide to Bearings and Bushings, Self lubricating Bushings

Bushing or Bearing, what’s the difference?

There’s really no difference: a bushing is a type of bearing. In general, a “bearing” facilitates movement between two parts while reducing friction. Simple in design, a typical bearing has two surfaces that roll against each other, allowing the two mating parts to move without friction.

What is a bushing?

The bushing is a cylindrical mechanical part set on the rotating shaft, and is a component of the sliding bearing. Generally speaking, the sleeve and the bearing seat using interference fit, and with the shaft using clearance fit.

The difference between bushings and bearings

The difference between the two is that the sleeve is a whole structure, the rotation is the relative movement between the shaft and the sleeve; while the bearing is a split type, the rotation is the relative movement of the inner and outer ring of the bearing itself. But in essence, the bushing is actually a kind of plain bearing.

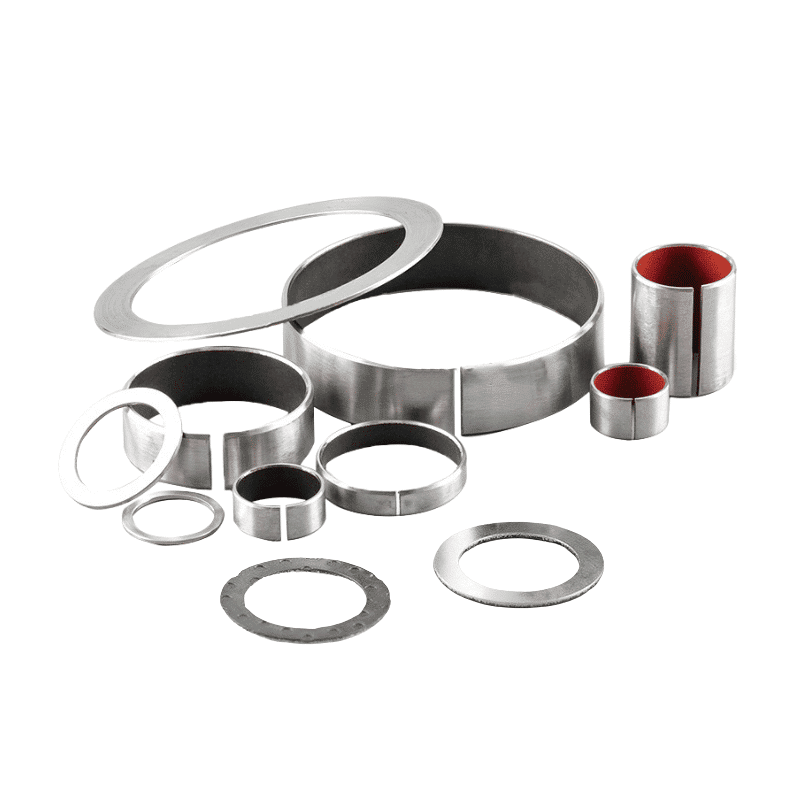

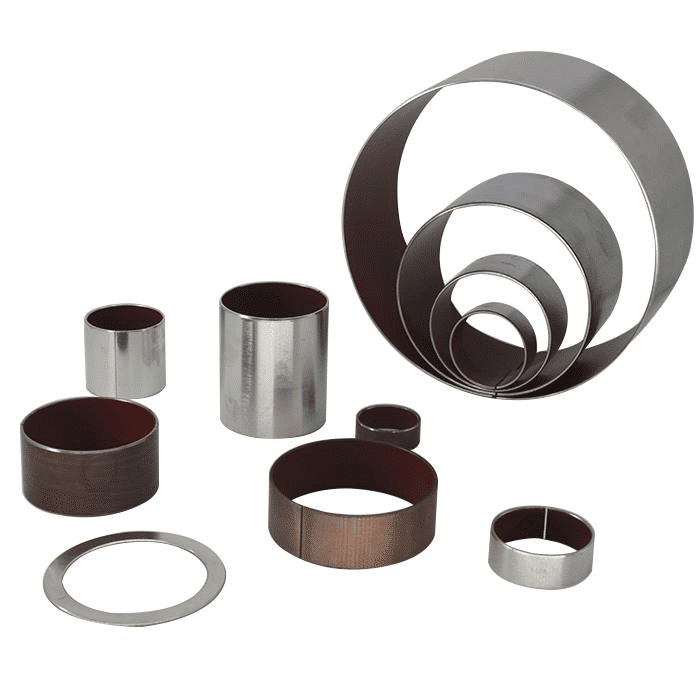

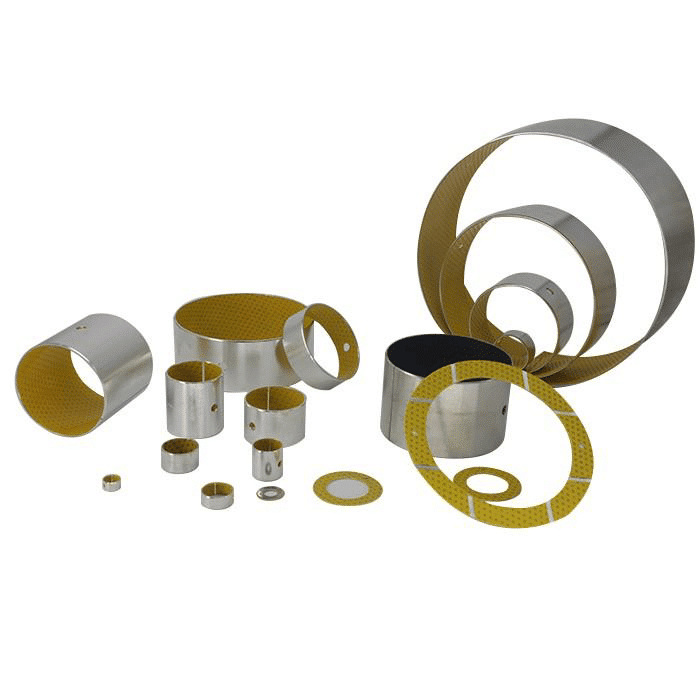

We offers the whole range of metal, polymer and resin bushes. Bushings, also sometimes named sleeve bearings, have low friction coefficient. They can be used dry or greased. They are used in rotative movements with heavy loads. The choice of the bushing depends on speed, temperature and load.

When applicable, our bushes are produced according to ISO 3547. See our catalogue for more details. We also provide lead-free bushings. Metal Polymer Bearing: Designed To Greatly Reduce The Transmission Of Noise And Vibration. High Quality. High Performance.

In industry, quality, sustainability and cost-effectiveness are all important factors in choosing bushing bearings products. Before identifying the value & price of the bushing bearings product, we generally need to describe its performance & characteristics, in accordance with legal norms, form a detailed document, the user will have quality to follow when buying. Let’s follow this thought path and explore the story behind Bronzelube.com self-lubricating plain bearing bush material products.

Want to run your system efficiently and still save money?

Choosing the right bearings bushing is important!

Rolling Bearings vs. Sliding Bearings, What’s the Difference?

A roller bearing is a cylindrical unit used to provide low friction movement for a bushing or housing. A ball bearing is a spherical unit with the same objective as a roller bearing. The real difference is the contact surface between the bearing and the track.

Using the best sleeve bushing materials around

Beautifully crafted leather products.

Today, as light weighting becomes the mainstream of industrial design, we are all seeking more optimized system space, more efficient system operation, and lower costs. All of this can only be achieved with customized friction reduction system solutions, and traditional rolling bearings are constrained by conditions that make it difficult to achieve light weighting and customization. Take a look at how customized bushing solutions for self-lubricating plain bearings can make systems run more efficiently and save money at the same time! ✦Less is more: Smaller bearings give you more ✦✦Lighter weight products. Compared to rolling bearings, self-lubricating plain bearings have smaller bore diameters and take up less space, so you can greatly optimize system space and save your production costs. Easy assembly: The simpler one-piece construction of the sliding bearing eliminates the need for complex operations during installation, saving you time and labor for installation.

High-quality bearing bushing

Beautifully crafted leather products.

Higher load capacity: Sliding bearings can withstand higher impact forces through face contact compared to point contact rolling bearings. Good partner for innovative design: Traditional rolling bearings are all standard parts and cannot be customized in size and shape, thus limiting the development and design of products. We can customize sliding bearing solutions to meet customer needs, so that your whims are no longer limited! Reduced post-maintenance!

Self-lubrication can be achieved in some applications, which not only reduces environmental pollution, but also allows for maintenance-free operation, greatly reducing post-maintenance costs. Quietness: Sliding self-lubricating bearings use a unique composite structure that has less surface friction and vibration than rolling bearings, effectively reducing the noise of your equipment. Want to run your system efficiently and still save cast? Choosing the right sliding bushing or bearings is important!

Always self-lubricating, Always long-lasting

Bearings – High Performance, POM Bushing Or Other Composite Bushing

They can be plain polymer ( such as POM) or layered with mesh of PTFE and a structure with epoxy resin and glass fiber. Put a variety of different engineering composite bushings bearings together to do performance comparison, to find the one suitable for plain bushing bearing, this process is not easy. The first thing to look at is the composition of the composite bearing material. In this step you may be confused by countless materials with strange names. They have many fancy names and claim to be versions of “Teflon”, “POM”, “PTFE”, “3 layer”, “Sliding Material” “Oilless Bushing Material”and “Dry Bearing Material”. Not surprisingly, most self-lubricating bearings are specific mixtures made from the same small molecules that come together and have special chemical names. Typical polymers that can be used as bearings are PTFE, POM, some materials with high temperature resistance or other characteristics such as PEEK, PTFE Fabric… So how exactly do we compare? There are many useful tools, such as data sheets on the famous network, sample books on self-lubricating bearing materials and, of course, books on the subject of self-lubricating sliding bearing materials. But the key question is, how do you know which one to use? Flanged wrapped Bushing, available with flange or washer shape. Some plates are on stock. Other on request!

Top quality

Polymer bushings are used in a lot of different situations. Small minimum order cost or quantity, Savings potential up to 40%. Submit an inquiry!

Custom Plain Bushings

We Offer Our Vast Inventory of High-Quality Bushings. Search Catalog. View Bushing Bearings Type. Order Online.

Cylindrical Wrapped Bushing, POM≠POM Composite Bushing, The Right Bushing Material for Your Project!

Explore the catalog of bearings bushings, bronze bushes and bearings of all types. Discover the wide range and fill out the form: you can also request custom bushing drawings! High level experts. Efficiency & reliability.

PTFE BEARINGS

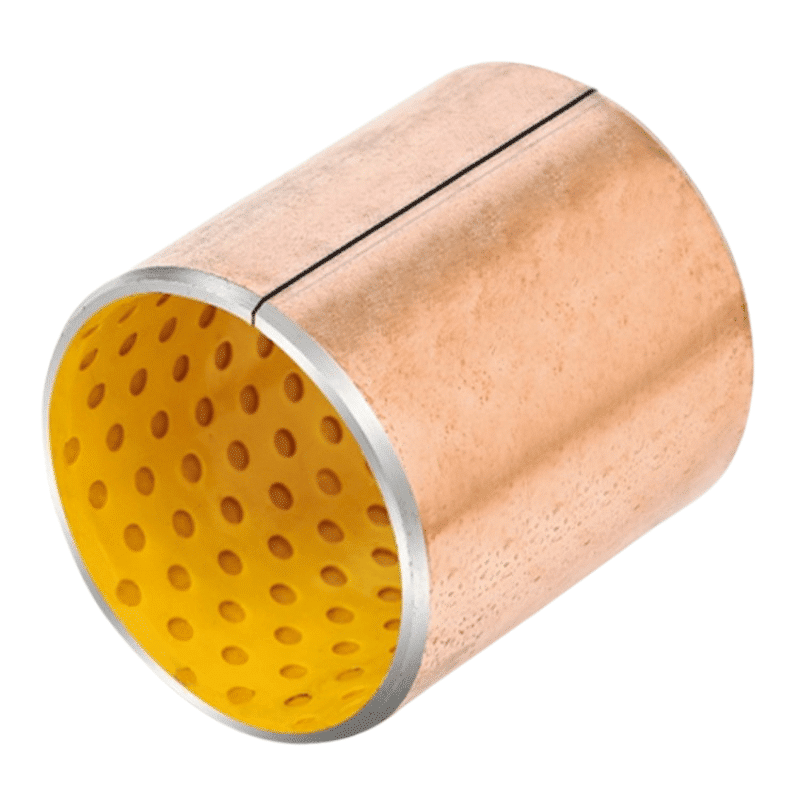

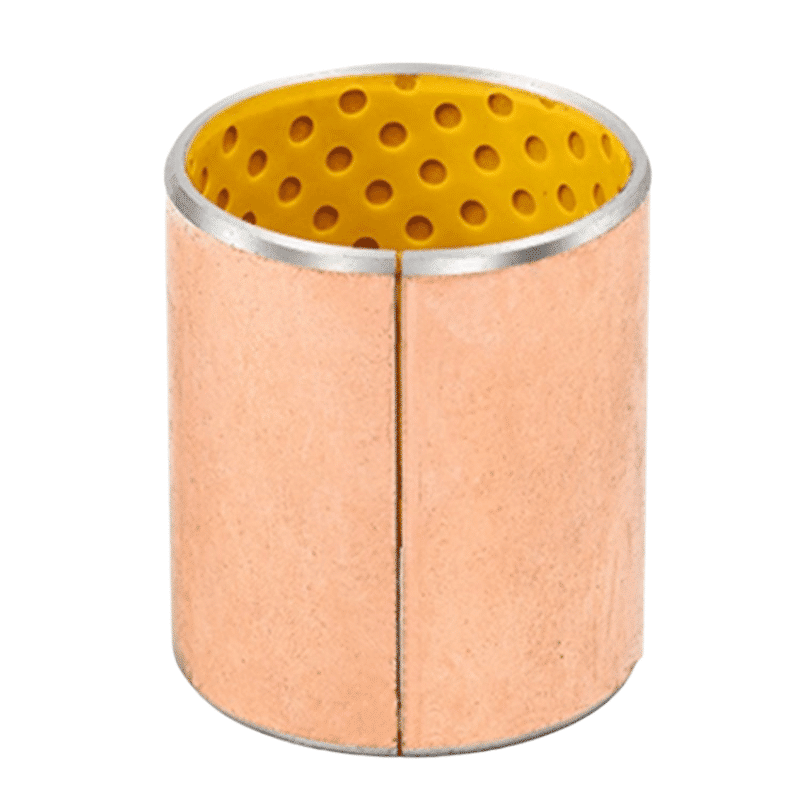

The bushing has 3 layers : a steel or bronze strip to improve mechanical resistance – a porous sintered bronze layer for heat conductivity, dimensional stability and the bonding of the sliding layer – a PTFE based sliding layer with good auto lubricant quality (low wear and low friction).

Polymer Bush

The polymer bushing has a composite structure : a steel layer – a porous sintered bronze layer – an alveolate acetal surface. POM usually refers to is not pure POM, pure POM can not meet the requirements of bearing life. In order to visualize this, we tested all composite bearing materials on a standardized test platform, and of course, the same tests were carried out on a variety of competing products. Test parameters include but are not limited to: load, speed, load type and motion type to detect wear of samples.

Request a Quotation for Your Sleeve Bearings

* Cylindrical, flanged, washer or special shape. Dimensions are checked according to ISO 3547. Application area examples for plain bushings are:

- agricultural machinery

- hoisting equipment

- construction machinery

- forestry machinery

Find a bushing in your area, today.

Discover the extraordinary potential of plain bushing bearing data for your specific applications! We offer a comprehensive range of self-lubricating bearing materials, catering to diverse requirements and budgets.

Our collection includes a wide spectrum of self-lubricating composite bearing metal bushings, spanning from affordable options to top-of-the-line solutions. With such a variety at your fingertips, finding the perfect sliding bearing for your application has never been easier.

Whether you prioritize cost-effectiveness or seek unmatched durability, our platform allows you to compare and analyze data from different materials. By calculating and comparing various options, you can make informed decisions tailored to your specific needs. Additionally, you have the option to download data sheets, empowering you with detailed technical information. To ensure the utmost credibility, we provide highly realistic test data. Our comprehensive testing procedures deliver accurate and reliable results, reinforcing the quality and performance of our bearing materials. This transparent approach guarantees that you can make well-informed choices based on verified information.

We understand the significance of choosing the right bearing material for your application. That’s why we offer comprehensive support throughout your decision-making process. Our knowledgeable team is available to address any questions you may have and provide expert guidance. Contact us today to unlock the magic of plain bushing bearing data. Experience the convenience of comparing options, accessing detailed information, and benefiting from realistic test data to make confident decisions. Let us help you find the perfect self-lubricating bearing material that aligns with your requirements and delivers optimal performance.

Choose Your Lubricated Bronze Plain Bearing & Best Bushing Material!

Grease-free & Plain Bushing Benefits: Bushings are effective in reducing the transmission of shock and vibration between components. In the automotive industry, the use of self-lubricating bushings in shock absorbers has many benefits, including improved safety and comfort while driving, minimized noise and damage due to reduced vibration.

Plain Bushing Design Guide

Plain bushing design guide, Self-lubricating, Low cost Bearing Design, Low Weight, We make your prototype, You receive your finished bushing bearing product!

Strong and Flexible.

Find your bushing material, Maintenance-free, we almost always offers a solution. For plain bearings, the physical property table usually lacks parameters directly related to the suitability of plain bushing bearing materials, such as wear resistance, which is a key consideration for bushing bearing life.

Easy Installation Bushing

Lean assembly: easy installation, Two times longer service life at high loads, *Need Assistance? Call Or Email Us Engineering Support Available

We manufacturer sleeve bushing plain bearings tailored to your needs.

Bushing Material Selection

Selecting the right bushing material for an application is important to ensure proper functioning, longevity, and reliability. The choice of material will depend on factors such as the type of load, the operating conditions, and the required level of wear resistance.

Here are some commonly used bushing materials and their properties:

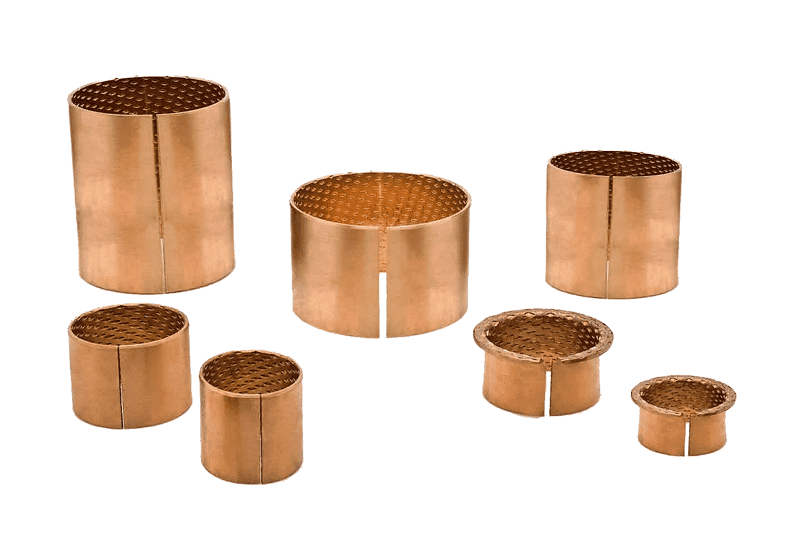

Bronze: Bronze is a commonly used material for bushings because of its good wear resistance, high load capacity, and low friction. It is also resistant to corrosion and chemical attack, making it suitable for use in harsh environments. Bronze bushings are often used in applications such as heavy machinery, hydraulic cylinders, and pumps.

Brass: Brass is another material commonly used for bushings. It has good corrosion resistance, high conductivity, and low friction, but is not as wear-resistant as bronze. Brass bushings are often used in applications such as electric motors and appliances.

Plastic: Various types of plastic, such as nylon, acetal, and polyurethane, can also be used for bushings. Plastic bushings offer low friction, good wear resistance, and are lightweight. They are often used in applications where noise and vibration need to be minimized, such as in office equipment and vehicles.

Steel: Steel bushings are durable and have high load capacities, but can be prone to corrosion. They are often used in heavy machinery and construction equipment.

When selecting a bushing material, it is important to consider factors such as the load capacity, operating temperature, lubrication requirements, and expected service life. The material should be compatible with the mating parts to prevent wear and damage. Additionally, the cost and availability of the material should also be considered.

Bushing Material: An Overview

Bushings, also known as plain bearings, are mechanical components designed to provide a smooth and frictionless surface between two moving parts. These components play an important role in many industrial and engineering applications, as they are responsible for reducing friction and wear between rotating parts, as well as absorbing vibration and shock. Bushings are available in a wide range of materials, each with its own set of properties and applications.

The most commonly used bushing materials include:

Bronze: Bronze bushings are made of a mixture of copper and tin, and are known for their high strength, durability, and resistance to wear and corrosion. Bronze bushings are commonly used in heavy-duty applications, such as in industrial machinery and equipment.

Brass: Brass bushings are made of a mixture of copper and zinc, and are known for their high resistance to corrosion, good wear resistance, and low friction. Brass bushings are commonly used in applications where corrosion resistance is important, such as in marine environments.

Steel: Steel bushings are made of high-carbon steel, and are known for their high strength, durability, and resistance to wear and corrosion. Steel bushings are commonly used in applications where high load-bearing capacity is required, such as in heavy-duty machinery.

Plastic: Plastic bushings are made of various types of plastic materials, including nylon, polyethylene, and polytetrafluoroethylene (PTFE). Plastic bushings are known for their low friction, lightweight, and resistance to wear. They are commonly used in applications where low friction and low weight are important, such as in automotive and consumer products.

Bushing Type: An Overview

Bushings are available in a wide range of types, each designed for specific applications and requirements. The most commonly used bushing types include:

Sleeve bushings: Sleeve bushings are cylindrical in shape, and are designed to provide a smooth surface between two rotating parts. They are commonly used in applications where low friction and low wear are important, such as in automotive and industrial machinery.

Flanged bushings: Flanged bushings have a flange on one end, and are designed to provide a secure connection between two parts. They are commonly used in applications where a secure connection is required, such as in construction and heavy-duty machinery.

Split bushings: Split bushings are designed to be split into two halves, making them easier to install and remove. They are commonly used in applications where ease of installation and maintenance is important, such as in industrial machinery and equipment.

Self-lubricating bushings: Self-lubricating bushings are designed to provide a lubricated surface without the need for external lubrication. They are commonly used in applications where external lubrication is difficult or impossible, such as in harsh environments or in applications with limited access.

Self-Lubricating Bearing Material: An Overview

Self-lubricating bearing materials are engineered materials that are designed to reduce or eliminate the need for external lubrication, thus reducing friction and wear. This is achieved by incorporating solid lubricants, such as molybdenum disulfide or graphite, into the material.

The most commonly used self-lubricating bearing materials are composites made of a metallic matrix, such as steel or aluminum, combined with a solid lubricant. These composites can be formed into various shapes, including bushings, bearings, and thrust washers.

One of the key benefits of self-lubricating bearing materials is that they can operate with low friction and minimal wear, even in harsh environments where traditional lubricants may fail or be difficult to apply. This makes them ideal for applications where lubrication is difficult, such as in high-temperature environments, vacuum conditions, or where contaminants would affect the performance of traditional lubricants.

Self-lubricating bearing materials are widely used in a variety of industries, including automotive, aerospace, and industrial machinery. They are also used in applications where maintenance costs and downtime must be minimized, such as in wind turbines, nuclear power plants, and off-highway vehicles.

In conclusion, self-lubricating bearing materials are a type of engineered material that provides long-lasting, low-friction performance without the need for external lubrication. These materials are used in a variety of applications where traditional lubricants may be impractical or ineffective, and are essential for reducing wear, extending equipment life, and minimizing maintenance costs.

What is the difference between bearings and bushings?

Bushings vs. Bearings. What’s the difference and how to choose.

Bushings vs. Bearings, Bushings are a category under the general category of bearings. Bushings are thin tubes or sleeves that allow relative movement by sliding (our product type) as opposed to rolling. Bushings are also referred to as sleeve bearings. However, the term sleeve bearing seems redundant. Thus, a bushing is a bearing, but a bearing is not necessarily a bushing. A bearing is a friction component that allows relative motion of two parts or surfaces, etc.

Bearings or bushings are both used primarily to reduce wear and tear on moving parts. The main difference lies in the respective applications and where they fit. Choosing the right type of bushing or bearing for your industrial purpose to meet certain requirements requires a great deal of knowledge. You need to know the difference between bushings and bearings, the main types of bearings and bushings, their applications in industry and manufacturing, and much more.

All machines consist of moving parts, many of which require bearings and bushings to facilitate their movement without creating friction. They mainly help to reduce noise, increase service life, reduce power consumption and maximize machine efficiency and speed applications.

We will begin by learning the main differences between Bushings and Bearings.

Bushings vs. Bearings. Main Differences

Bushings and bearings are used to reduce friction, resulting in low tearing of high moving parts. Although one may be mistaken for the other, they are both suitable for their separate applications, environments and situations.

In the case of a bushing, it is a cylindrical component that supports the load of a sliding moving shaft running between two surfaces. On the other hand, a bearing supports a shaft in rotary motion while providing a form of position between them. Simply put, a bearing has two rings that operate with a metal ball between them to reduce friction and ensure smooth rotation of one surface relative to the other. A bushing is a bearing that slides on a shaft or rod, resulting in extremely low frictional movement.

What is a bushing? A bushing – often referred to as a sleeve bearing – is a cylindrical element that supports a load on an operating shaft, sliding back and forth between moving surfaces. A bushing is a single element component that can be constructed of a variety of materials. The bushing slides over the rod or shaft, providing a motion with very low friction, good vibration damping, and reduced energy use, noise and wear.

What are the types of bushings?

There are many types of bushings on the market with different material compositions. Some are excellent at controlling high pressures and shocks, while others can withstand corrosion. You can choose the ideal type of bushing for your industrial or manufacturing application and operating environment.

Bushings can be classified based on two main factors; material and shape. There are three common types of bushings according to material, including composite bushings, metal bushings and plastic bushings. There are four other types of bushings based on shape, including cylindrical plain bushings, flanged bushings, thrust washers, and sliding plates.

Types of bushings by material

1. Polymer or composite bushings

Polymer bushings, also known as composite bushings, are better at carrying heavy loads. These are the most commonly used bushings because they have low friction and wear resistance. Polymer or composite bushings reduce the breakage of equipment due to improper lubrication of components.

In addition, polymer or composite bushings can be used to convey rotary motion when at least one of the two friction components in a machine or micro mechanism is composed of a polymer. Polymer or composite bushings can be used in environments where conventional bearings would be hazardous.

These bushings can be used in a range of industries including construction equipment, hydraulic systems, medical equipment, aerospace, etc.

Composite bushings are further divided into the two main types mentioned below.

POM composite bushings: POM bushings are primarily used to reduce vibration and noise in machinery. Since composite bushings are usually made of durable materials, this makes them ideal for reducing bearing wear.POM composites also help to reduce heat build-up caused by friction. This helps extend the life of bearings up to four times longer than other traditional materials, such as steel.

PTFE composite bushings: This is a type of bushing made using two different materials, including Teflon and metal. These types of bushings are used as bearings in a variety of industrial applications. Their core purpose is to reduce friction between moving parts in machinery.

2. Metal bushings

As the name implies, these bushings are made of metal or metal alloys and have a two to three layer structure with steel backing. These bushings have a very high mechanical strength, making them suitable for high speed and load applications involving lubrication. The metal used depends on the industrial environment or the type of application. These bushings are available in different lubrication methods, depending on their size, composition and application. Metal bushings, including bronze bushings.

Slide Bushing or Rolling Bearing, what’s the difference??

Manufactures slide bushings in various designs and from different materials. Therefore, We offers a wide assortment of bushings available from stock.

Rolling bearings utilize balls (ball bearings) or cylindrical rollers (roller or “needle” bearings). These elements are contained in the bearing ring or “collar” where they facilitate movement with little to no sliding resistance. Ball bearings are the most common type and can carry radial and axial loads.

However, rolling bearings can be affected by failure modes such as load damage, when the seat ring is deformed by the rolling element due to load, or if the ball is overloaded the ball will be deformed, due to repeated loading under static conditions and pseudo-hormonal damage caused by wear due to insufficient lubrication and oscillating motion. Cylindrical roller bearings are designed to carry heavier loads, and they have greater contact with the raceway, thus spreading the load over a larger area. However, they are not suitable for applications involving thrust loads.

There are differences between sliding and rolling bearings. Due to their complex multi-part design, precision construction and precise mounting, rolling bearings tend to be much more expensive than plain bearings. Rolling bearings are better suited for applications that require precise shaft positioning and/or very low friction. Slippery bearings have higher load capacity and are resistant to high shock loads and edge loads due to their larger contact area and adaptability. Sliding bearings compensate for misalignments better than some rolling bearings to reduce the effects of edge loads. The sliding bearing’s slim one-piece design reduces housing size, resulting in significant space savings and weight reduction. Sliding bearings have greater resistance to damage from oscillating motion, which extends bearing life. Sliding bearings operate at high speeds and low loads without wear damage due to slippage of the rolling elements and have excellent damping properties. There are no internal moving parts in a plain bearing, resulting in quieter operation and virtually unlimited speed ratings under properly lubricated systems compared to rolling bearings. Mounting the plain bearing directly into a simple housing virtually eliminates assembly damage compared to rolling bearings. Non-metallic plain bearings have higher corrosion resistance than standard rolling bearings. Plain bearings can run dry, eliminating lubrication, lubricants in maintenance and additional costs associated with equipment downtime. Plain bearings can operate dry at high temperatures and in the presence of contaminants.

How do you know, what kind of bushing material with better performance?

General-purpose steel-based self-lubricating bearings without oil feed without oil lubrication or less oil lubrication, can be in use without or less maintenance. Good wear resistance, small friction coefficient, long service life. Has the right amount of elastic-plastic, can distribute the stress in the wider contact surface, improve the bearing capacity. The static and dynamic friction coefficient is close, so as to ensure the working accuracy of the machine. Can make the machinery reduce vibration, reduce noise, prevent pollution, improve working conditions. The transfer film can be formed during the operation to protect the grinding shaft. For grinding shaft hardness requirements are low, thus reducing the processing difficulty of related parts. Thin wall structure, lightweight, can reduce the mechanical volume. Steel back can electroplate a variety of metals, can be used in the corrosive medium; At present, it has been widely used in sliding parts of various machines.

- What do we customize for plain shaft bushing?

- Plain Bearing Bushing Sizes:We can customize the dimensions of our plain bearings.

- Plain Bearing Bushing Design: We have always focused on effective design of plain bearings, offering competitive pricing without compromising performance, quality and use.

- Plain Bearing Bushing Materials: We offer a wide range of friction self-lubricating materials, including metallic, bimetallic and non-metallic materials. Each material is available in different self-lubricating and requiring lubrication.

Bushing Design Guide, Bushing Bearing Online Sales

“This is a question that people often ask us: “How long will this material last?” In order to answer this fundamental question, in addition to providing written data, we decided to take a more practical approach — life calculation, which is backed by a huge amount of real data obtained from actual wear testing. To this end, we have built a professional test platform to allow a variety of materials to run for a long time in real conditions, such as any type of load, speed and different applications. At the same time, we also overlaid other more important parameters, including different bearing materials, material outer structure materials, environmental influences such as heat, extreme cold, dust, or chemicals. These can be highly close to the working condition data of bearings in practical application, so as to achieve the most realistic data.” Welcome to the Bushing Design Guide, Besides your will find the bushing bearings catalog. Can’t find the plain bearings size what you are looking for or have additional questions. Contact us today.

We offer customized plain bearings to meet your needs and applications. Our engineering team is happy to suggest and recommend the most suitable design, material, size, type, etc.

Self-lubricating Bushing Material, Buy Bronze Bushing Online

Wear resistance depends on a number of factors, of which the coefficient of friction is one, but the magnitude of the coefficient of friction itself depends on a number of different environmental factors. Most importantly, the physical properties of most plastic polymers are pretty much the same on the inside and the outside, so it’s hard to see any differences in key properties (such as density, thermal expansion, and flow resistance during injection molding) between composites with the same base material.

The use of additives, such as reinforced fiber, PTFE fabric, PEEK and so on, has a very small impact on the value in the physical property table, but it may greatly affect the wear and sliding performance of bearings. Even if the composition of the mixture is very small, it may also have a significant change on the service life of bearings.

In our material development projects, even a small portion of the pigment used to change the color of the material may determine the success or failure of bearing durability. Therefore, the physical property table has a certain role, but it is far from enough for us to evaluate the performance of bearings.

Types of bearing bushings by shape

In terms of shape, there are four main types of bushings.

Cylindrical general bushings: As the name implies, cylindrical bushings have a cylindrical shape, are made to industry standard dimensions, and are ready-to-install machine parts. Cylindrical bushings have a backing on the inside and outside that supports the sliding layer in the middle. Cylindrical bushings are stronger than bearings and can withstand higher forces than metal bearings, making them ideal for one-way variable loads, rotary motion and axially guided bearings.

Flanged bushings: Flanged bushings are almost identical to cylindrical bushings with one distinct difference, they have a flange at one end. The flange can serve a variety of purposes, from bushing mounting or alignment to ease of installation. They are commonly used in through-bolt applications, allowing the use of smaller diameter bolts to reduce weight without causing a reduction in the fastener’s bearing surface against the Spar wall, as well as reducing the stress on the threads of the mounting bolt.

Thrust washers: Thrust washers are not bushings per se, but are a very important component. They are essentially flat washers located between the fixed part and the rolling surface, supporting the axial load or movement on the shaft and, from the side, limiting any movement along the shaft. They form a surface on which the bearing or bushing is supported.

Sliding Plates: Sliding plates are a common component used in tool and die making. They are low maintenance and are popular in industries such as automotive, mechanical engineering, lifting, welding technology, injection molding machines and conveying technology.

Sliding plates are considered to be linear bearings and may be extension joints for bridges or other mechanical components. The principle is quite similar to that of a bearing or bushing. One of the plates is stationary and the other slides on it to counteract expansion or contraction. Sliding plates can be made of a variety of materials, from steel to PTFE, as well as self-lubricating metallic materials.

“Why plain bushing bearing service life & reliability usually more important than the bushing price?”

If several plain bearings can meet the speed & load requirements you need, then the next thing to do is to compare prices. You’ll be surprised how much the price varies. Usually, bearings cost only a few cents each, but if the demand is high, the cost can increase rapidly. Especially in some long-term projects, where thousands or even millions of bearings are needed, you may want to use low-cost materials rather than expensive alternatives. However, please never compare prices alone, because the cost of bearing failure is usually much higher in terms of long-term costs. When purchasing decisions are made, they want to keep the purchase price low, and end users will do the same. The cost of each bearing is not only the direct cost of the purchase price, which may be surprising, “How long will the bearing material last”, “Can’t I just use a base metal polymer bearing?” These problems are difficult to judge only by the level of the purchase price.

Plain Bearing Life Time, Cost-effective Bushing, Excellent Price!

The cost of using bearings depends on the machinery and is sometimes enormous: during the intense harvest season, which lasts only a few days, the cotton harvester in the field breaks down; Or, in perfect climbing weather and on the track, the $2000 mountain bike starts rattling… Knowing how long a bushing bearing will work is priceless. For these applications that bring high use costs due to bushing bearing damage, it is very valuable to know in advance how long the plain bearing can last, and it is also an important factor to bring long-term use to your equipment and reduce the comprehensive cost. Replacing old bushing bearings and installing new one plain bushes is a painful business. You need to shut down all the equipment, the repairman takes out the bearings, and you need to unload everything around the plain bearings just to replace a mechanical part the size of a fingernail, which means a savings of only 20 cents on a $60,000 machine.

Your Plain Bushing Wrapped Bronze Bushes Cooperative Partner, Factory Price

We are willing to support you! Reduce costs, improve technology! The use of high quality bearing components is essential in any equipment in any field. From automobile to household equipment, from production equipment to electronic equipment, can use more cost-effective engineering plastic sliding parts.

As a high performance metal self-lubricating wear-resisting bearing parts experts, we can provide free samples and technical support through telephone and email, online quotation and standard size material self-lubricating bearings, to help you continue to improve!

Bushing Supplier

24/7 emergency callout