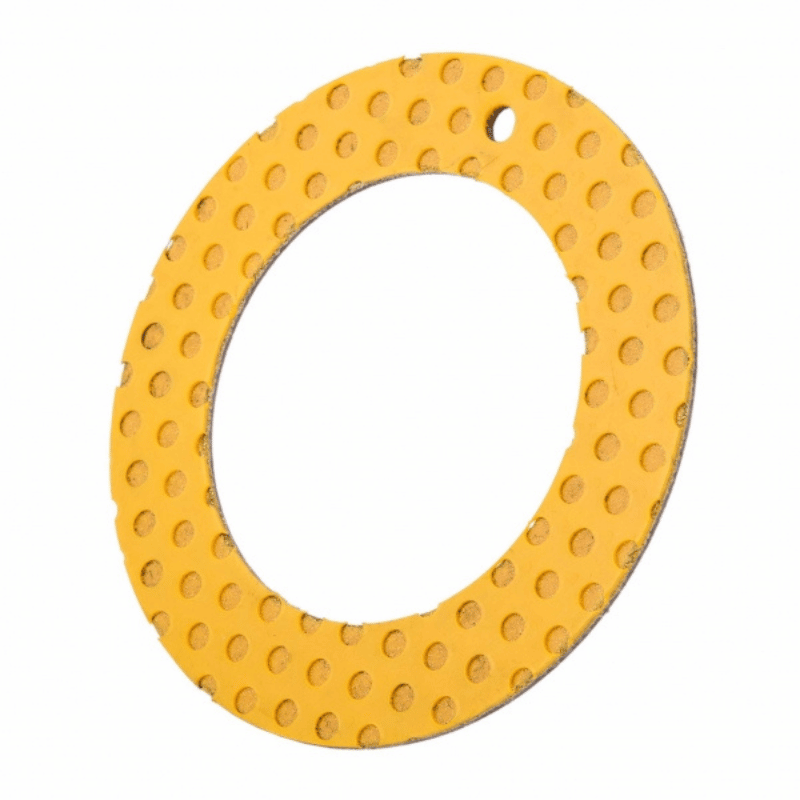

Thrust Washer Material

View your dx thrust washers metric size.

Dx is a composite bearing material developed specifically to operate with marginal lubrication, it is suitable for temperatures from -40 to +120 °C. Oil or grease lubricated washer. Dx Washer Bush – Pom Material

Imperial DX thrust washers operate in oscillating and rotary functions, needing less maintenance as re-lubricating periods are longer with less edge loading, absorbing of water and abrasion.

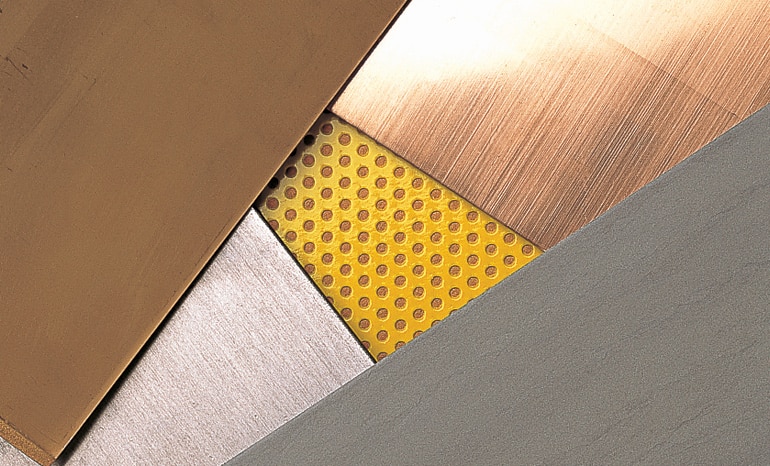

- Carbon steel shell with sintered bronze layer with a co- acetal polymer layer.

- Wrapped Bush

- Glacier Bush

Various Type Thrust Washer

Dx Split Bush Washer – Bearing Revolution.

Sintered POM and Bronze Powder on Steel Backing

- POM + Sintered Bronze Powder + Steel Backing + Copper / Ting-plating

Standard dx bushing & bearing available from stock.

- Cylindrical dx bushes

- Dx thrust washers

- Dx strip material pom

Non standard bearing not available from stock.

- These products are manufactured to customers’ requirements

Standard bushing

Customized dx washer, meet your requirement.

Thrust washer

Small minimum order value & quantity, fast delivery.

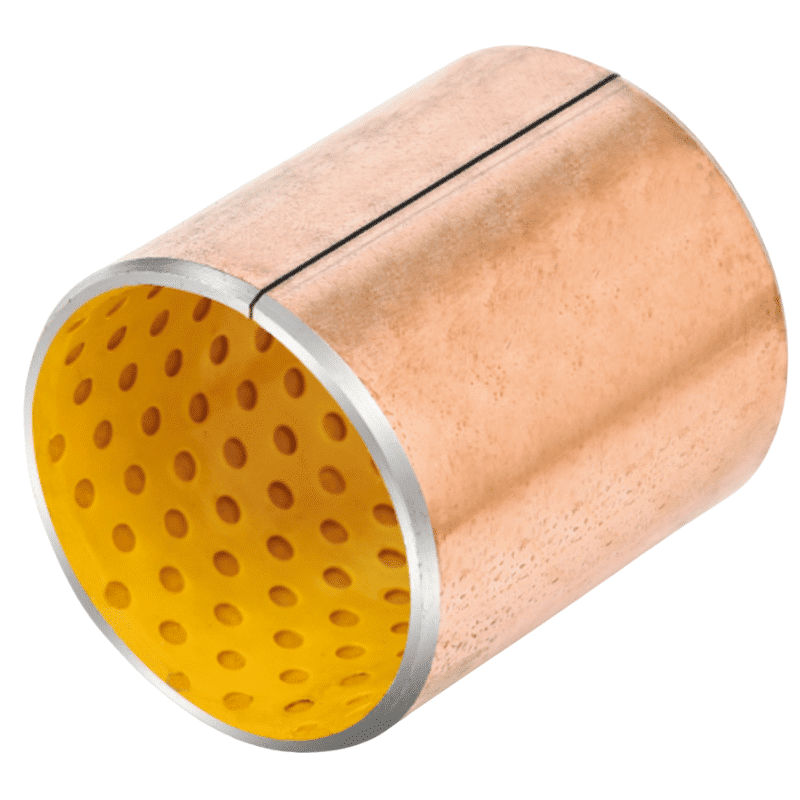

Metal-Polymer Plain Bearings Grease Lubricated

The excellent low friction and high wear resistance performance of metal-polymer pom bearings make them ideal for hundreds of applications in numerous and diverse industries. Depending upon application requirements, metal-polymer composite bushes can be produced in many shapes and sizes.

CHARACTERISTICS

- marginally lubricated pom bushings for grease or oil lubricated applications

- Standard parts contain grease marks in the sliding layer;

- smooth sliding layer available on request

- Optimal performance with relatively high loads and low speeds

- Suitable for linear, oscillating and rotating movements

- Wide range of parts available in stock

High performance self-lubricating bearing material

Metal-Polymer Plain Bearings Grease Lubricated Dx Bushing

Metal-Polymer Composite Bushing Material

- Steel Back + Porous Bronze Sinter + POM with Lubrication Indents

|

Axle

|

Code number

|

Washer size

|

Install size

|

|||||

|

d +0.25

|

D -0.25

|

T -0.05

|

M ±0.12

|

h+0.4

+0.1 |

t±0.2

|

D1+0.12

|

||

|

8

|

SF-2WC10

|

10

|

20

|

1.5

|

15

|

1.5

|

1

|

20

|

|

10

|

SF-2WC12

|

12

|

24

|

18

|

24

|

|||

|

12

|

SF-2WC14

|

14

|

26

|

20

|

2

|

26

|

||

|

14

|

SF-2WC16

|

16

|

30

|

23

|

30

|

|||

|

16

|

SF-2WC18

|

18

|

32

|

25

|

32

|

|||

|

18

|

SF-2WC20

|

20

|

36

|

28

|

3

|

36

|

||

|

20

|

SF-2WC22

|

22

|

38

|

30

|

38

|

|||

|

22

|

SF-2WC24

|

24

|

42

|

33

|

42

|

|||

|

24

|

SF-2WC26

|

26

|

44

|

35

|

44

|

|||

|

26

|

SF-2WC28

|

28

|

48

|

38

|

4

|

48

|

||

|

30

|

SF-2WC32

|

32

|

54

|

43

|

54

|

|||

|

36

|

SF-2WC38

|

38

|

62

|

50

|

62

|

|||

|

40

|

SF-2WC42

|

42

|

66

|

54

|

66

|

|||

|

46

|

SF-2WC48

|

48

|

74

|

2

|

61

|

1.5

|

74

|

|

|

50

|

SF-2WC52

|

52

|

78

|

65

|

78

|

|||

|

60

|

SF-2WC62

|

62

|

90

|

76

|

90

|

|||

1. The mixture of modified polyoxymethylene (POM) and lead is 0.3~0.5mm, which has high wear resistance and low friction coefficient even in the case of instantaneous oil shortage. There are regularly arranged oil storage pits with helical angles on the bearing surface, which must be filled with lubricating grease during assembly.

2. The copper powder layer is 0.2~0.3mm, which has good bearing capacity and wear resistance, and good thermal conductivity can transfer the heat generated during the operation of the bearing in time. The composite material can penetrate into the gaps of the copper powder balls, improving the bond strength.

3. Low carbon steel 0.4~2.2mm, improve bearing capacity and heat transfer.

4. Copper/tin plating layer, copper plating layer 0.008mm, tin plating layer 0.005mm, so that the bearing has good corrosion resistance.

Dx bushing properties

- High static & dynamic load capacity

High static & dynamic load capacity

High static & dynamic load capacity

Suitable for rotating, oscillating, reciprocating and sliding movements.

Dx bushings are prefinished and require no machining after assembly.

| GENERAL | Unit | Value | |

| Maximum load, p | Static

Dynamic |

N/mm2

N/mm2 |

140

140 |

| Operating temperature | Min

Max |

°C

°C |

– 40

130 |

| Coefficient of linear thermal expansion | Parallel to the surface | 10-6/K | 11 |

| Normal to the surface | 10-6/K | 29 |

Thrust Washer Bearing Applications

Agriculture Products

Automotive

Machine Tool Construction

Where Re-lubing is a problem

Please Note: Imperial DX washers are measured inside diameter x outside diameter in inches!!!

| Matching Bearings | ||||

| Material | Part Number | Inner Diameter | Outer Diameter | Thickness |

| Wrapped Acetal Lined POM Washer | POM 12 24 1.5mm thickness washer | 12 | 24 | 1.5 |

| Wrapped Acetal Lined POM Washer | POM 14 26 1.5mm thickness washer | 14 | 26 | 1.5 |

| Wrapped Acetal Lined POM Washer | POM 16 30 1.5mm thickness washer | 16 | 30 | 1.5 |

| Wrapped Acetal Lined POM Washer | POM 18 32 1.5mm thickness washer | 18 | 32 | 1.5 |

| Wrapped Acetal Lined POM Washer | POM 20 36 1.5mm thickness washer | 20 | 36 | 1.5 |

| Wrapped Acetal Lined POM Washer | POM 22 38 1.5mm thickness washer | 22 | 38 | 1.5 |

| Wrapped Acetal Lined POM Washer | POM 24 42 1.5mm thickness washer | 24 | 42 | 1.5 |

| Wrapped Acetal Lined POM Washer | POM 26 44 1.5mm thickness washer | 26 | 44 | 1.5 |

| Wrapped Acetal Lined POM Washer | POM 28 48 1.5mm thickness washer | 28 | 48 | 1.5 |

| Wrapped Acetal Lined POM Washer | POM 32 54 1.5mm thickness washer | 32 | 54 | 1.5 |

| Wrapped Acetal Lined POM Washer | POM 38 62 1.5mm thickness washer | 38 | 62 | 1.5 |

| Wrapped Acetal Lined POM Washer | POM 42 66 1.5mm thickness washer | 42 | 66 | 1.5 |

| Wrapped Acetal Lined POM Washer | POM 48 74 2.0mm thickness washer | 48 | 74 | 2.5 |

| Wrapped Acetal Lined POM Washer | POM 52 78 2.0mm thickness washer | 52 | 78 | 2.5 |

| Wrapped Acetal Lined POM Washer | POM 62 90 2.0mm thickness washer | 62 | 90 | 2.5 |

Dx Marginally Lubricated Bearings Standard Parts – Dx Thrust Washer.

Metal-Polymer Plain Bearings Grease Lubricated Dx Washer Material Structures

- POM thickness 0.30~0.50 mm

- Sintered bronze powder thickness 0.20-0.35mm

- Low-carbon steel

- Copper/Tin plating thickness 0.002mm

Discover Wrapped Acetal Lined dx thrust washer made by viiplus on www.bronzelube.com.

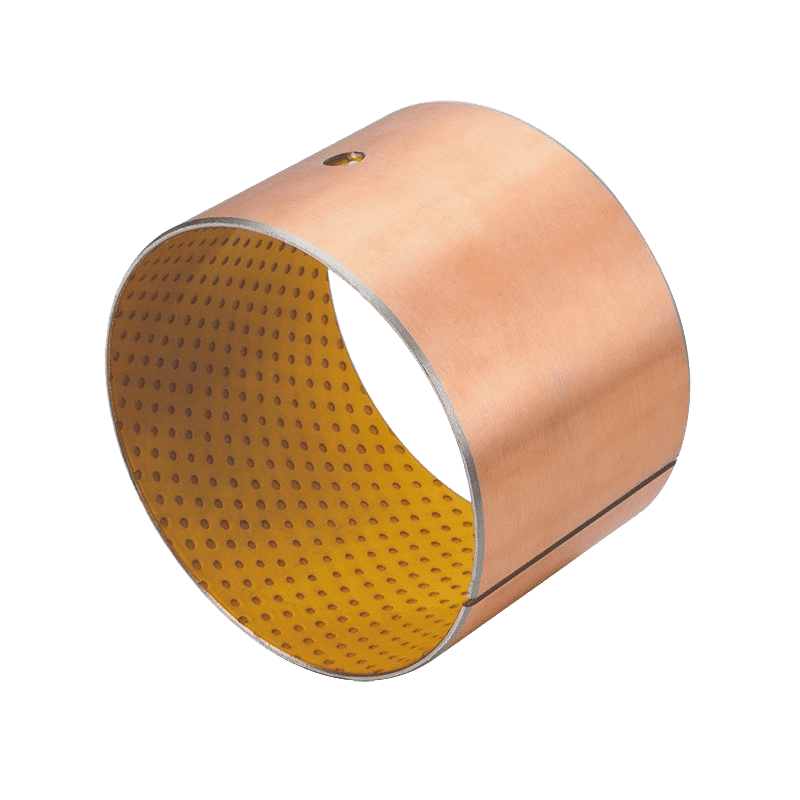

The dx washer is widely used in different application.

Our washer range of wrapped acetal lined washers are suitable for rotary and oscillating movement applications.

The POM washers are made from carbon steel and with a sintered bronze layer and an acetal co-ploymer layer. Our machining service is able to produce non-standard sizes to suit customer specific requirements.

- Automotive

- Machine tool building industry

- Agricultural equipment

* The dx acetal washer bushings are suitable for rotating and oscillating movement, less maintenance requirements due to the long re-lubrication intervals, lower wear, lower susceptibility to edge loading, no absorption of water and therefore no swelling, good damping behaviour, good resistance to shock loads.

Metal-Polymer Plain Bearing Material Grease Lubricated Supplier, Acetal Lined Washer

Switch from Bearing – Metal-Polymer – Maintenance-Free Bushes Solutions

Metric bushes and imperial bushes made to order: standard self-lubricating bearing forms in special dimensions, half-bushings, special shapes obtained by stamping, bearings with locating notches, lubricant holes and machined grooves, customized bushing designs, Explore composite thrust bearings washer products from china

Acetal Lined Washer

24/7 emergency callout