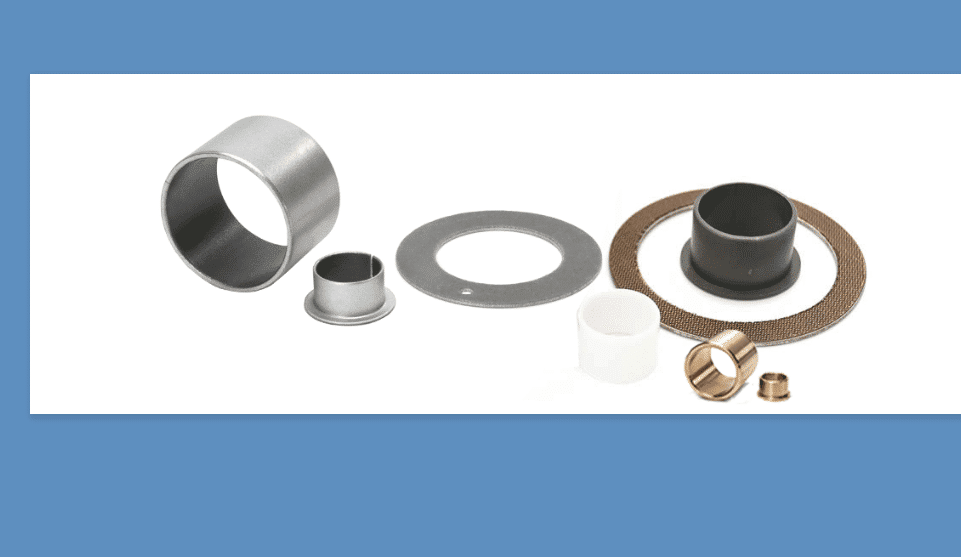

Oil Free Bushing – Multi Layer, Straight & Shouldered Online Sourcing

ManufactureProperties and Applications of Teflon Fabric,

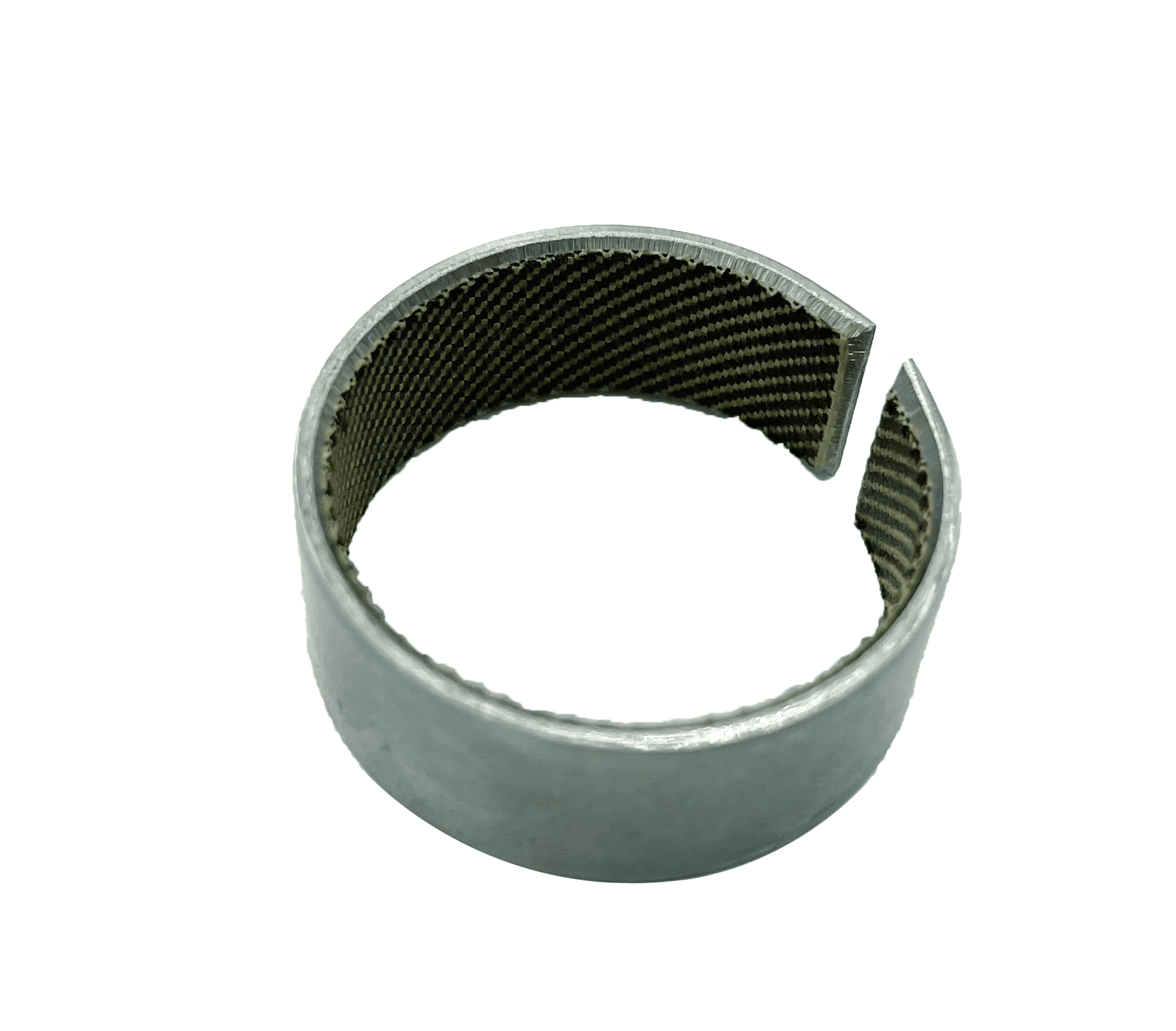

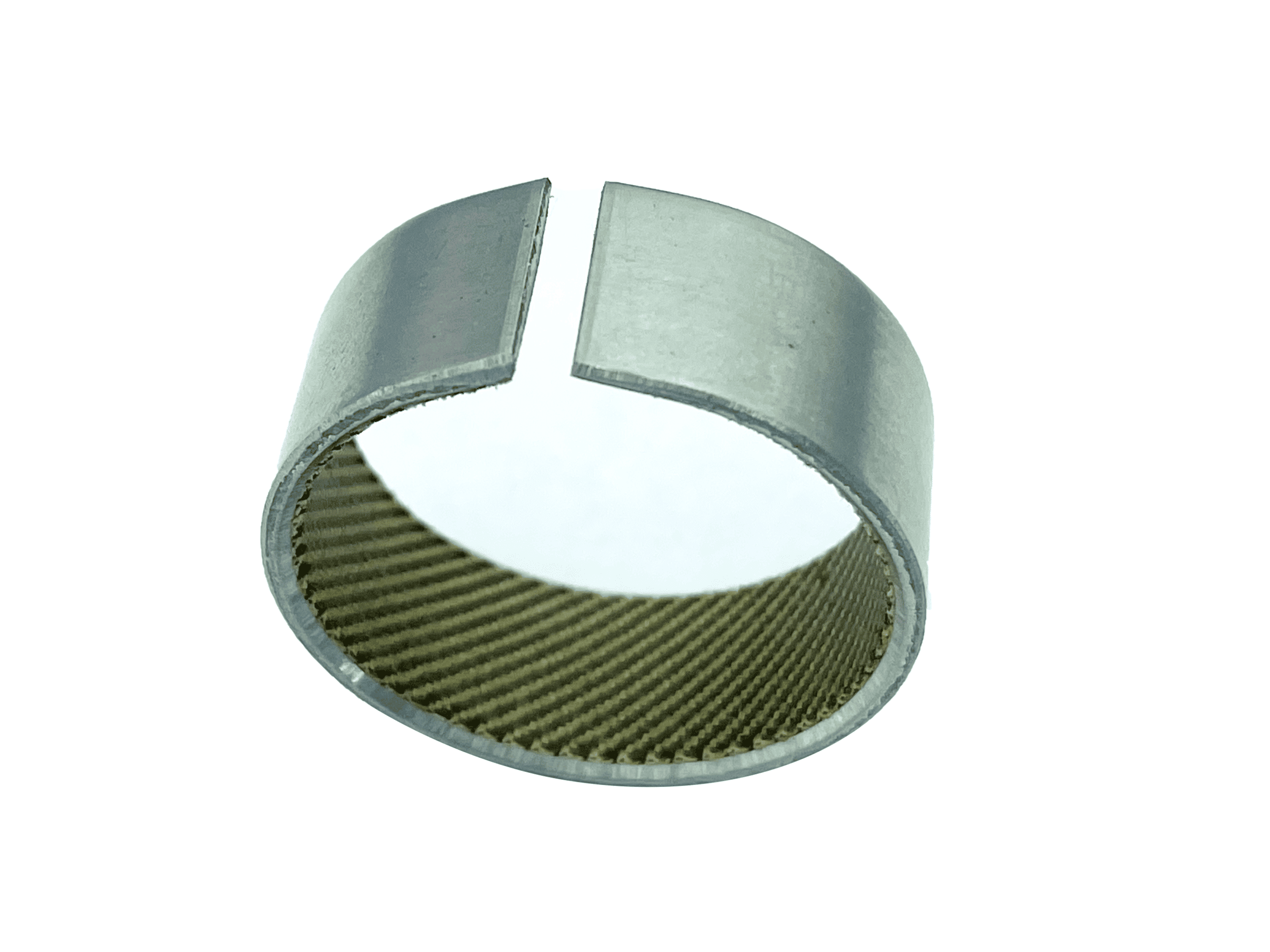

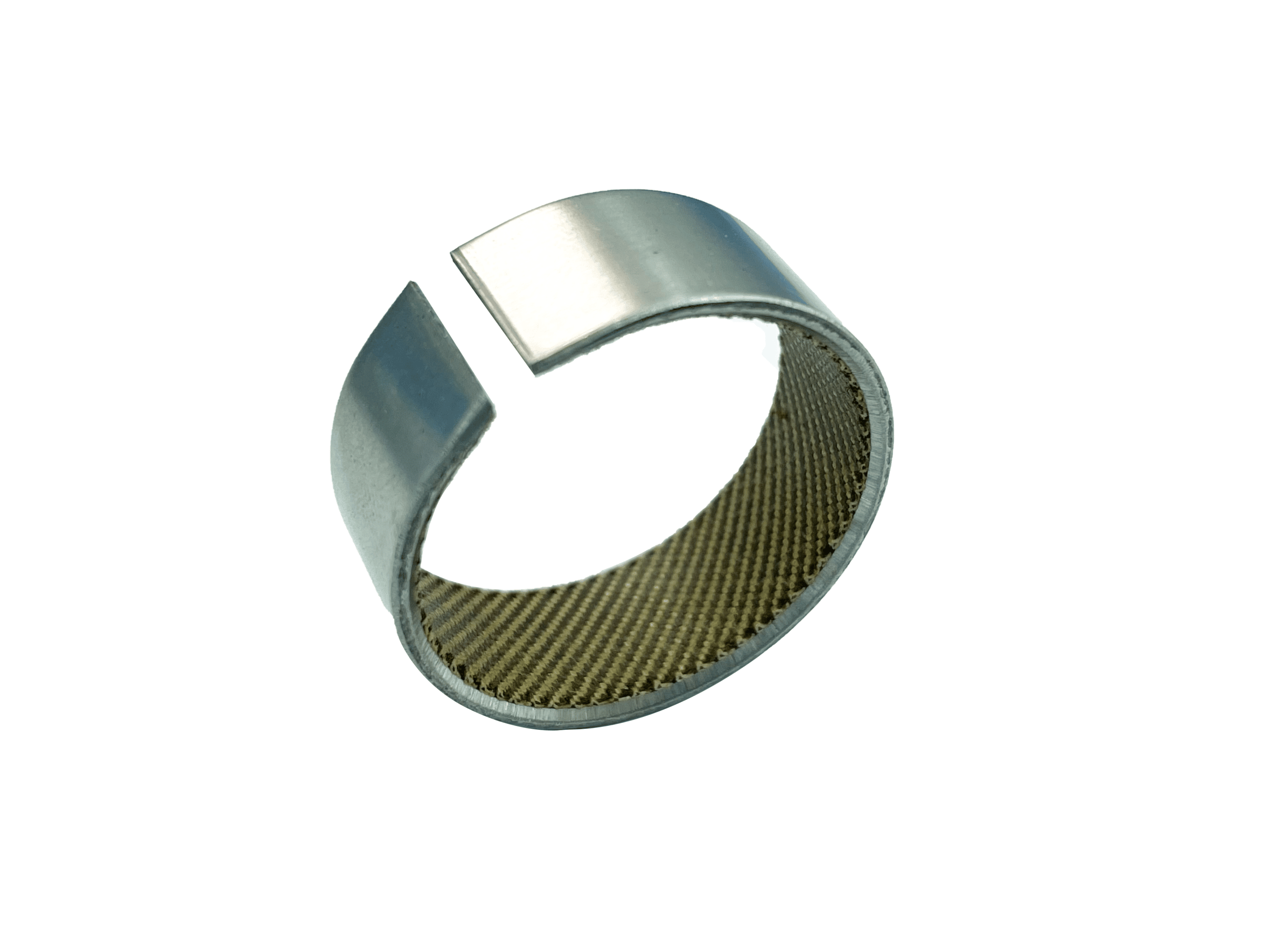

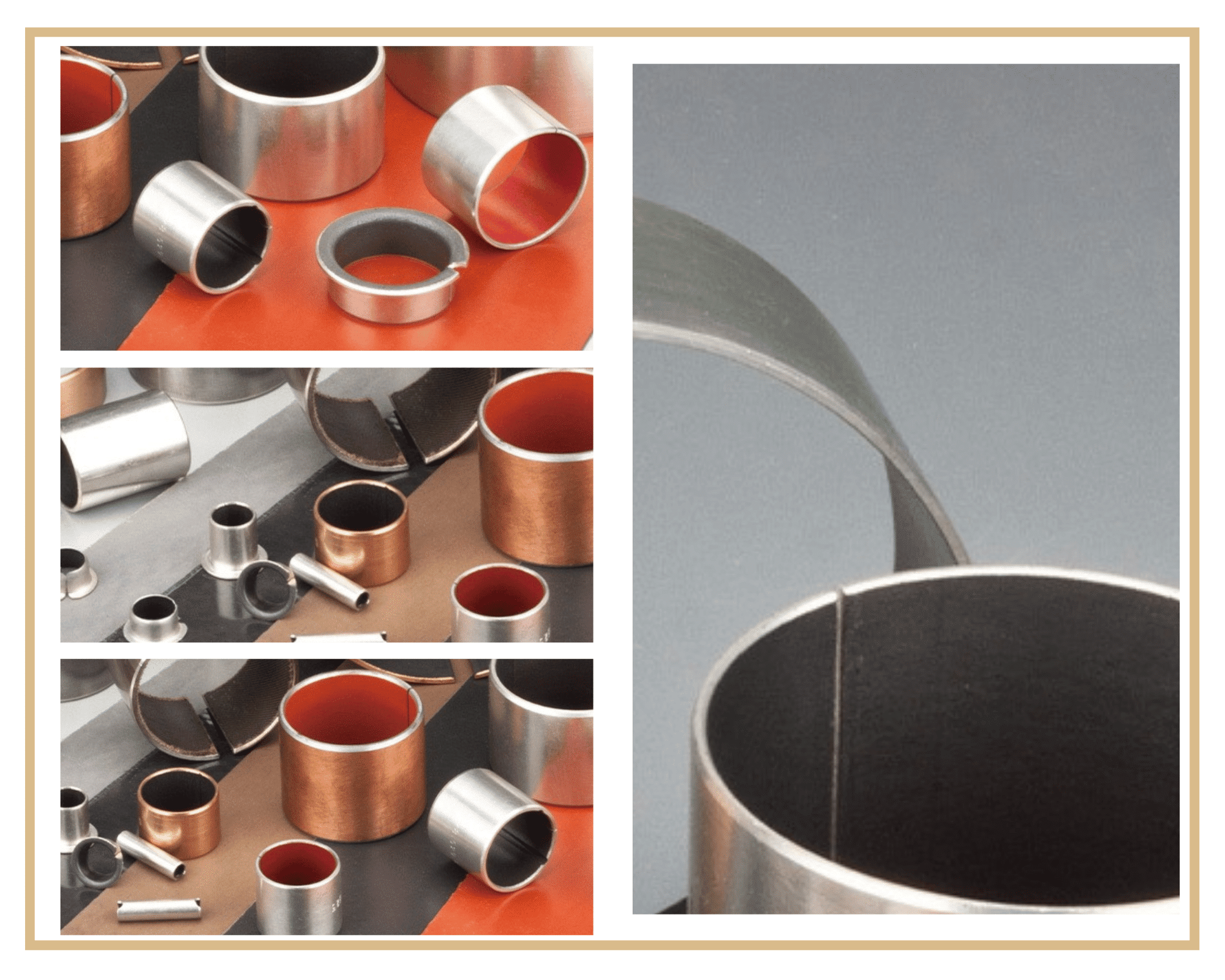

Self Lubricating Bushing – split seam, steel, “Journal Bearing”, Standard Series

QUALITY ENGINEERED BEARINGS:

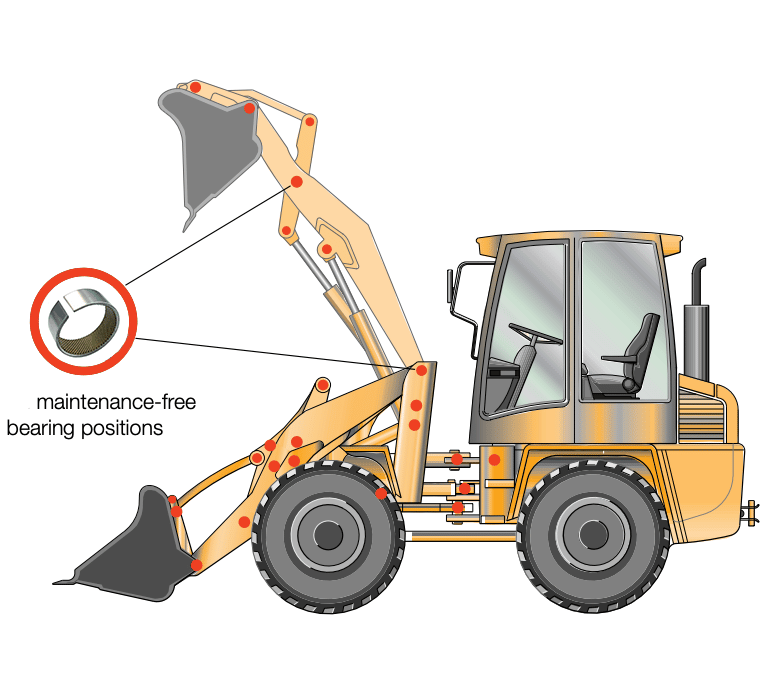

Self-lubricating bearing material very good wear and low friction performance over a wide range of loads, speeds…coiled steel journal bearings are designed to meet industry standards for self-lubricating bushings. They provide all of the advantages of fabric bearing bushing at minimum cost. Carbon steel is normally used as a backing material, with the external surfaces plated to resist corrosion. Typical applications include automotive vehicles, farm equipment, construction and material handling equipment.

Self-lubricating sliding bearings

Cold Rolled Steel, Wear Parts & Plain Bearings, Metallic Bearings.

self lubricating bearings consist of a woven PTFE fabric with strengthening fibres applied to a metal backing. self lubricating bearings are typically used in valves, hydro power equipment, lifting equipment and many other applications. Valve manufacturers value the stainless steel 316 Kevlar bushing grades due to their high load carrying capability and chemical resistance.

We are supplied with a range of metal backings bushing. These include stainless steel 316, carbon steel, and bronze. self0lubricating bearings are supplied as coiled bearings, thrust washers, and solid cylindrical bearings. Kevlar reinforced high-performance plain bearing & bushings material Kevlar fiber helps to strengthen the cable and prevent breakage.

Bushing Design

PTFE Slide Bearing Compound Options. Glass fiber / graphite compound. Glass fibers increase the load-carrying capability of the sliding material

Sliding Bearings, Maintenance-free PTFE Bushings Supplier

Learn More

High compressive strength

Self lubricating Kevlar Bushing

The metal backing is chosen to be suitable for the application and is usually chosen from mild steel, zinc plated mild steel, stainless steeL 316, brass or bronze. The composite bushings material of compounded PTFE, bronze stretched metal and stainless steel backing. Bearings are metal-reinforced, self-lubricating sliding bearings with a … metal backing, PTFE compound, material structure, shape, and geometries. PTFE fabric bearings are available in a range of metric sizes. GLIDE STRIPS: Metal backed strips (straight and curved)

Machined and lined shapes (e.g. vertical & horizontal control pads for Hydro-electrical applications) are available on request.

- Superb stability under vacuum

- Long service life

- High impact strength

- Insensitivity to moisture

- Excellent strength retention

- Low noise

Top Quality

The ability of Stainless Steel backed bearings to work in both dry and wet conditions without grease lubrication means they are used in a wide variety of applications within the Hydropower industry.

Woven Glide Bushing

Which gives high performance in main guide plain bushing bearings

Our capabilities include component design, self-lubricating material selection, prototype, production, and manufacturing.

It is a composite material made from woven synthetics fibers bonded with the resin including a friction modifier. Self-lubricating provides high compressive strength, durability, dimensional stability, and low friction. Its excellent wear characteristics promote long life, and in turn, reduce maintenance costs for the end-users.

The standard PTFE compound contains carbon and graphite. Special PTFE compounds are available on request. Fabricated parts include roller bearings with or without an axial flange, deep-drawn bearings, and die-cuts. The metal backing is available in stainless steel for use in chemically-harsh environments.

Self-lubricating metal-backed system for rigorous applications.

Standard Thickness

Improve & extend the performance of Self-lubricating composite for high load, low-speed applications. Superb stability under vacuum

- Long service life

- High impact strength

- Insensitivity to moisture

- Excellent strength retention

- Low noise

Ask The Expert

Engineering assistance & self-lubricating material selection support.

Polytetrafluoroethylene (PTFE) fabric is a composite material consisting of PTFE, fabric or aramid fiber, among other components. It is crafted through specific weaving methods and undergoes specialized impregnation treatment. This results in a fabric known for its high strength and low friction coefficient. When used in spherical plain bearings, this fabric not only retains the bearings’ high-load bearing and self-aligning properties but also adds the benefits of self-lubrication, impact resistance, and extended lifespan. These self-lubricating bearings are highly applicable in advanced fields such as aviation and aerospace, particularly in critical load-bearing areas.

Keywords: PTFE Fabric, Liner Application, Self-Lubricating Spherical Plain Bearings

Self-lubricating spherical plain bearings are essential in numerous cutting-edge technological fields. The performance of the self-lubricating materials is crucial in ensuring that these bearings can handle heavy loads, resist impacts, and have a long service life. PTFE fiber fabric, as a novel polymer material, offers excellent toughness, high strength, and low friction, making it an ideal material for bearing lubrication layers. This paper briefly introduces the use of this material in spherical plain bearings.

Polytetrafluoroethylene Fiber Fabric:

This fabric is a blend of PTFE fibers and other fibers, woven into a double-layer fabric with various textile structures like plain, twill, or satin. The fabric’s surface, rich in PTFE fibers, serves as the low-friction contact surface. The other side, composed of high-strength bonding fibers, forms the bonding surface. This dual-layer structure utilizes the low friction of PTFE and the high strength of the fibers, often reinforced with materials like Kevlar, aramid, glass, or carbon fiber.

Performance of PTFE Fiber Fabric:

PTFE fabric’s friction surface creates a solid lubricating film capable of enduring extensive friction cycles. The fabric’s friction coefficient is remarkably low, even lower than that of molybdenum disulfide and graphite. When in contact with metal, the heat generated reduces the shear strength of PTFE, enabling it to adhere to the counter-abrasive surface and form an effective lubrication layer. Additionally, the fabric boasts high load-bearing capacity, wide temperature tolerance, excellent corrosion resistance, and strong bonding fastness due to impregnation treatment.

Application in Spherical Plain Bearings:

The PTFE fabric replaces traditional coatings or liners in spherical plain bearings, significantly improving self-lubrication. The key manufacturing processes involve bonding and extrusion, where the fabric’s strength and elasticity play a vital role in ensuring no radial or axial clearance in the bearings. This enhances the manufacturing quality and performance of self-lubricating spherical plain bearings.

Prospects for PTFE Fiber Fabric:

The future development of PTFE fabric aims to enhance its load-bearing capacity, reduce the friction coefficient for higher swing speeds, and broaden its temperature range applicability. As the product range expands, it will elevate China’s self-lubricating spherical plain bearings to fully meet the demands of high-tech industries, contributing to the advancement of sectors like aviation and aerospace.

Plain Bearing Applications, Self-Lubricating Bearings, and Wear Parts

The applications for plain bearings are vast and varied, particularly when they are designed with self-lubricating features. A prime example of such a bearing is the high-temperature resistant type, which includes a metal backing. These bearings are adept at functioning in demanding conditions. Thrust washers also benefit from a metal backing, often reinforced with Kevlar for enhanced performance. This high-performance Kevlar bushing material is particularly useful in rotor vanes of compressors and vacuum pumps.

One noteworthy application of polytetrafluoroethylene (PTFE) fabrics is in plain bushings. These bushings are characterized by their controlled friction, exceptional abrasion resistance, and longevity. Woven PTFE layers are particularly effective in a myriad of applications, such as in bushes, bearings, thrust washers, and sliding pads. They demonstrate their value in diverse equipment like slaughtering machines, packaging machinery, escalators, and glass bottle cleaning apparatus, offering prolonged life and low wear rates which in turn reduce operating costs.

In wastewater processing equipment and lock gate bushes, woven PTFE layers are utilized due to their excellent wear resistance and dimensional stability. The woven PTFE layer, when combined with self-lubricating Kevlar bushings, creates a robust and versatile material. It offers high mechanical strength and wear resistance, with a low coefficient of friction. This makes it suitable for applications like hydraulic cylinder head bearings and crane bearings. It can function effectively in both dry conditions and when used with common lubricants.

In more demanding and heavily loaded applications, woven PTFE layer bearings backed with metal are a preferred choice. These are often used in oscillating and sliding bearings found in packaging equipment and forming machines, where their durability and performance are essential.

- Are self lubricating and operate without external lubrication.

- Are free from stick slip, giving easy movement and operation.

- Are composite in nature and do not have the cold flow tendencies of solid and filled PTFE resins.

- Have high wear resistance giving long life.

- Can operate at temperatures beyond the range of most lubricants -150C to +300C

- Are corrosion resistant so can be used with aggressive liquids such as sea water, gasoline, acids, detergent solutions, hydraulic oils, ammonium hydroxide, oils.

- Are strong and can carry loads up to 420 N/mm2 for stainless steel and Inconel.

- Have good dimensional stability and the capacity to be formed to close tolerances.

Standard Thickness Table |

|||

| Nominal thickness (mm) | Material Structure | ||

| Stainless Steel 316 | |||

| 0.50 | • | ||

| 0.75 | • | ||

| 1.0 | • | ||

| 1.50 | • | ||

MICROSECTION

Microsection of self-lubricating bearings and bushings

bearing is a composite material of compounded PTFE tape on a metal shell. This material structure enables machining of the bearing in the housing–which is an alternative to the sizing process–to obtain tightest tolerances on the inside diameter.

The very thick PTFE layer isolates noise and allows to design bearings without play. Bearings of more than 0.75 mm thickness can be produced with an interference fit in the housing. Various methods are available to protect the steel shell from corrosion.

Sliding layer

PTFE + Fabric Woven Glide Bushing

Porous Bronze Sinter

Stainless Steel Backing

Plain Bearings Technical Library

Spec sheets, design worksheets, case studies & brochures

Engineered Plain Bushing Solutions

Engineering Assistance | Material Selection | Component Geometry

Request for quotation.

Related Characteristics

- Metal-Polymer Composite Self-lubricating Bushing Material

- Stainless Steel Back + Porous Bronze Sinter

- PTFE Fabric

stainless steel/316+PTFE/ fabric

The material is made of all kinds of high-quality metals, and the surface is covered with PTFE and other additives, which are low friction and friction-resistant fabric materials. This material structure has a higher carrying capacity, high-temperature resistance, and longer service life than the general three-layer composite material. The base material is stainless steel 316, etc. It is mainly used in the high-temperature production lines, construction machinery, automobile chassis parts, ball valve, butterfly valve, water pump, chemical industry, and high-speed train and other heavy load and low speed but can not refuel occasions.

| Max.Load | Static | 350N/mm·m | Temp: | -50℃-250℃ |

| Dynamic | 180N/mm·m | Friction coefficient | 0.03-0.20 | |

| Max.Speed | Dry | 0.5m/s | Thermal conductivity | 42W(m·k) |

| Lubrication | >1m/s | |||

| Max.PV(Dry) | Short-term | 3.6N/mm·m·m/s | coefficient of thermal expansion | 11*10k |

| Continuos | 1.8N/mm·m·m/s |

OPERATING PERFORMANCE

Dry Very Good

Oil-lubricated Good

Grease lubricated Fair

Water lubricated Fair

Process fluid lubricated Fair

AVAILABILITY

Plain bearing type s available in standard dimensions

- Cylindrical bushes

- Flanged bushes

- Thrust washers

- Flanged washers

- Sliding plates

Metal-Polymer Anti-Friction Plain Bearings

CHARACTERISTICS

- Self-lubricating bushings offer very good wear and low friction performance over a wide range of loads, speeds and temperatures in dry running conditions

- Sleeve Bushing material suitable for lubricated applications

- Anti-friction bearing suitable for linear, oscillating and rotating movements

Whether you need engineering assistance or self lubricating material selection support, our Ask the Plain Bearings Experts feature provides a quick and easy way for you to upload your drawing and submit questions to our engineering team.

Our technical plain bearing bushings experts are ready to help you with:

- Material selection for your specific application

- Engineering assistance in the geometry and function of your part

- Prototypes of self-lubricating bearings, to your specifications, for testing purposes

- Manufacturing and fabrication of your custom components

- Selection of in-stock bearings to fit your application

Bronzelube the Advantage Is Yours

- Low friction coefficient

- Use in both dry and wet conditions

- High compressive strength

- Low water swell

- Self-lubricating

Manufacturing

Manufacturing Self-lubricating bearing materials allow us to offer custom blends and unique sizes that others simply can’t. Producing our own raw materials in-house enables us to implement your designs on time, and on budget, giving you a strategic advantage over your competitors.

Metric Size & Inch Size Bushing. Special dimensions are available on request.

Bushings Catalog – Search Bushings Size

CAD DRAWINGS

Get access to bushing equivalent drawings

The application of polytetrafluoroethylene fabrics to spherical plain bearings

PTFE fabric is a high quality composite fabric with high strength and low friction coefficient woven from PTFE and Kevlar fiber by special weaving process and impregnation treatment. With such a fabric, the spherical plain bearing will have the advantages of self-lubrication, impact resistance and long life, while maintaining the original high load-bearing and self-aligning characteristics. Therefore, this kind of spherical plain bearing has a wide range of applications in heavy-duty critical positions in aviation, aerospace and railroad fields.

Customized Combines stainless steel-backed kevlar bushing & tape to provide noise and vibration damping properties and light-weight construction.

$18,999

Self-lubricating composite bushing.Fabric

Fiber bearings can be used in seawater, gasoline, hydraulic oil, motor oil, kerosene, lubricating oil, weak acid, ammonia, liquid nitrogen, toluene, washing liquid and other media. Installation of bushing: Teflon fiber metal-based self-lubricating bearings are generally thin-walled structure, relatively easy to change. Therefore, when assembling, according to the size of the inner diameter of the sleeve, use the corresponding method to install.

Save your purchasing Stainless Steel backed with PTFE woven fabric budget for your project.

High-Performance

Always tested. Always proven. Global website Stainless Steel Backed Kevlar Bushing Reinforced High-Performance Material

Use in both dry and wet conditions

Self lubricating Bearings, Metal Backed Self Lubricating Bearings.

Specialist in developing high-performance bushing & composites bearings, Stainless Steel (AISI 316) backed kevlar bushing, high temperature resistant materials, metal-backed sleeve kevlar bushing & self-lubricating bearing bushings solutions.

High impact strength bushings materials: like for stronger braided polymers — maybe a better Kevlar.

Stainless Steel backed with PTFE woven fabric bearing materials is extremely versatile and suitable for the most demanding applications in the most arduous environments.

- Long life

- Low friction coefficient

- High performance in dirty conditions

* Our enterprise, is one of the undisputed suppliers of the highly competitive Long service life stainless steel bushings industry in china. Explore More High Temperature Materials & Kevlar Bushing Bearings Products from china

Self Lubricating Bearings

Browse, get a quote and order products easily in Oil Free Bushing – PTFE, Flanged (fabric) eCatalog

Choose from our selection of PTFE bushings in a wide range of type and sizes. … Self-lubricating bushing fabric, the metallic bearings have high load and More wear and corrosion resistance…

Call us

24/7 emergency callout