The Power of Plain Sleeve Bearings: An Overview of Our High-Precision, Low-Noise Solutions

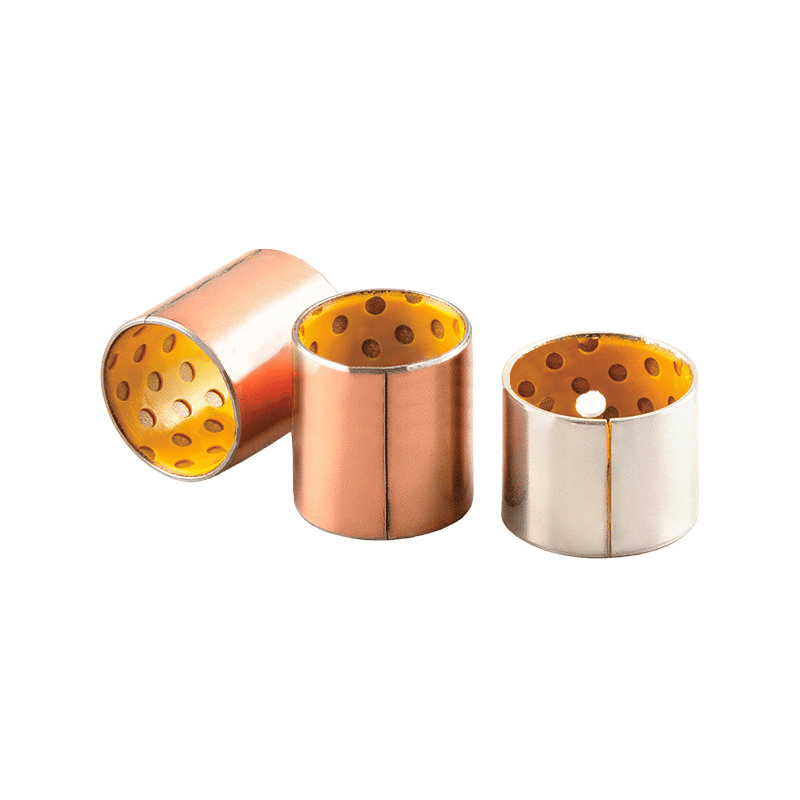

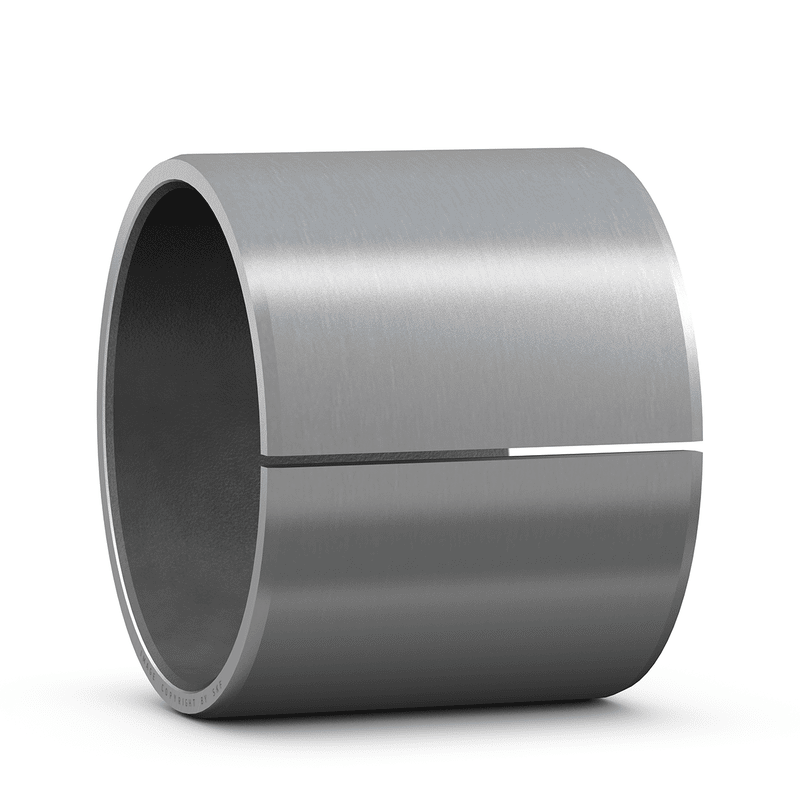

In the world of manufacturing and industry, there’s a silent, indispensable component that keeps our machines running smoothly: bearings. Plain sleeve bearings, in particular, are often the unsung heroes behind your machinery’s reliable performance. We are proud to be a leading manufacturer and supplier of these essential elements, boasting a broad range of industry experience within our management team. Our lineup includes Plain Sleeve Bearings, Oilless Bearings, Bronze Bushes, and more. We are dedicated to providing a reliable and cost-efficient solution for your operations, with the promise of low costs and high-quality products.

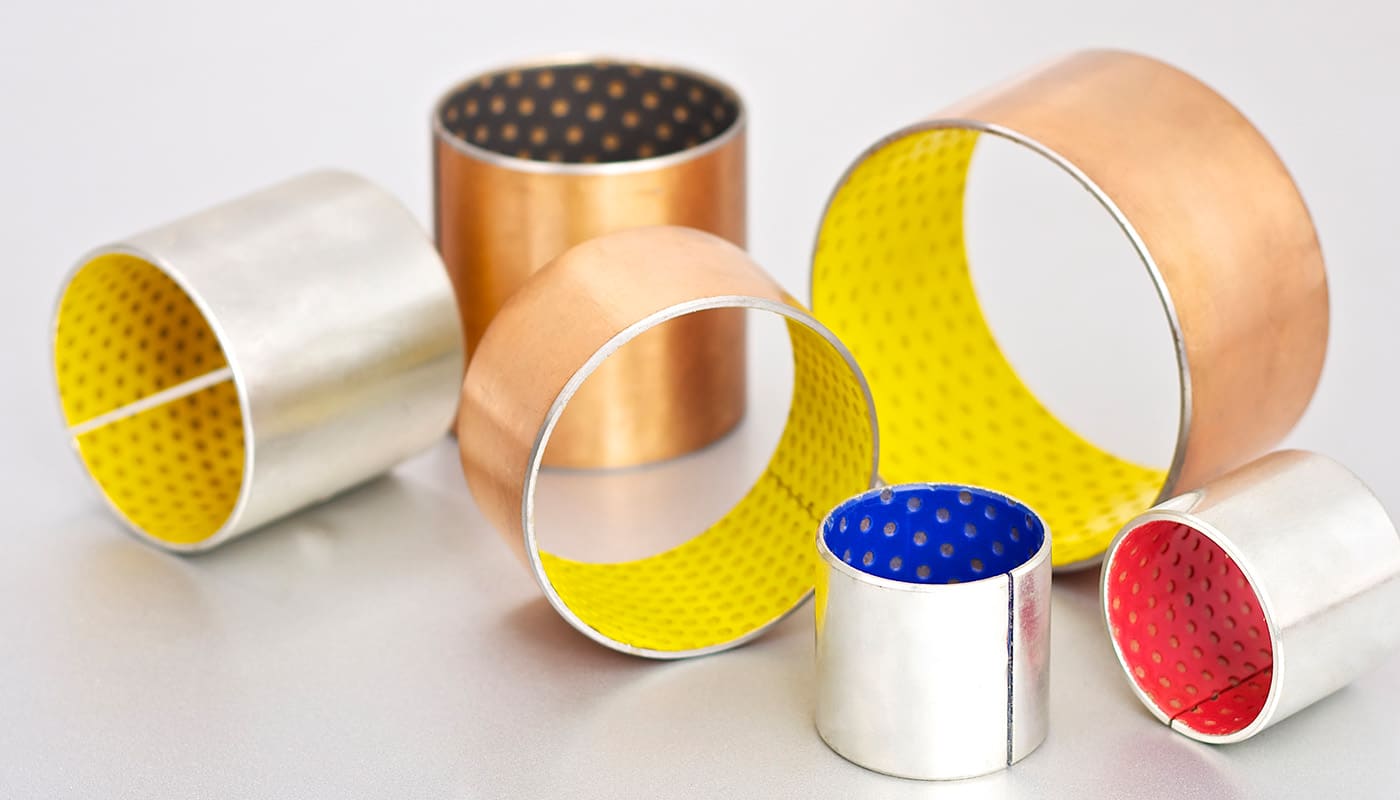

Expansive Range of Sliding Bearing Material

specializing in sliding Bearing, Advanced Sliding Bearings – Optimize Your Operations

: Elevate your equipment with our precision-engineered sliding bearings. Ideal for high-load applications. Explore our range now!

We are a premier Self Lube Bushings Sliding Bearings Manufacturer based in China, renowned for delivering high precision, low noise, and long-lasting products. Precision is our guiding principle when it comes to manufacturing Plain Bush Bearings. Our internationally certified manufacturing process, coupled with our stringent quality control measures, ensures that we produce bearings of unmatched quality.

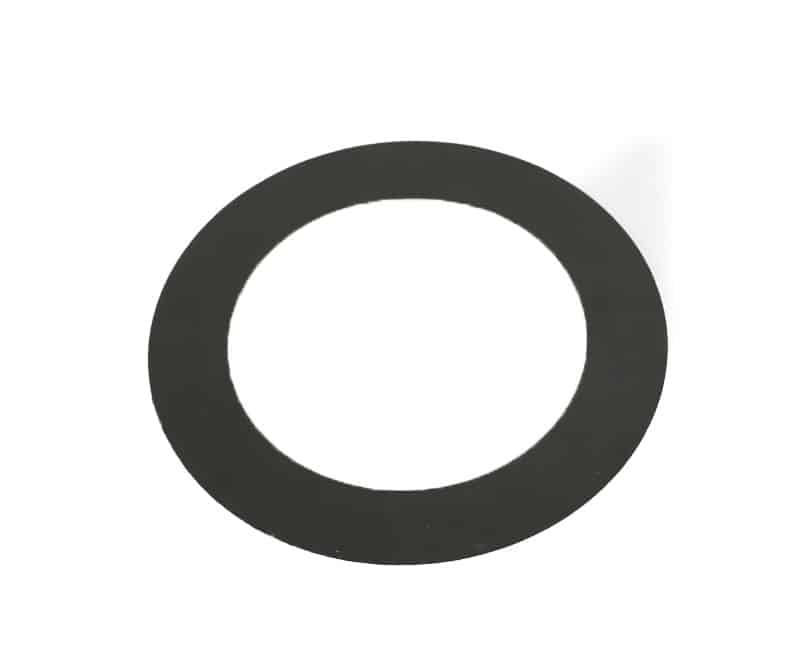

In the world of bearings, there’s a material that stands out for its versatility, robustness, and reliability – PolyTetraFluoroEthylene, or PTFE. PTFE bearings, renowned for their premium quality and resilience, offer excellent performance in a myriad of applications. They provide a unique combination of properties that make them a top choice for many industries. Let’s delve into the distinctive qualities and advantages that our range of premium PTFE bearings offer.

Customized Bushings for Unique Applications

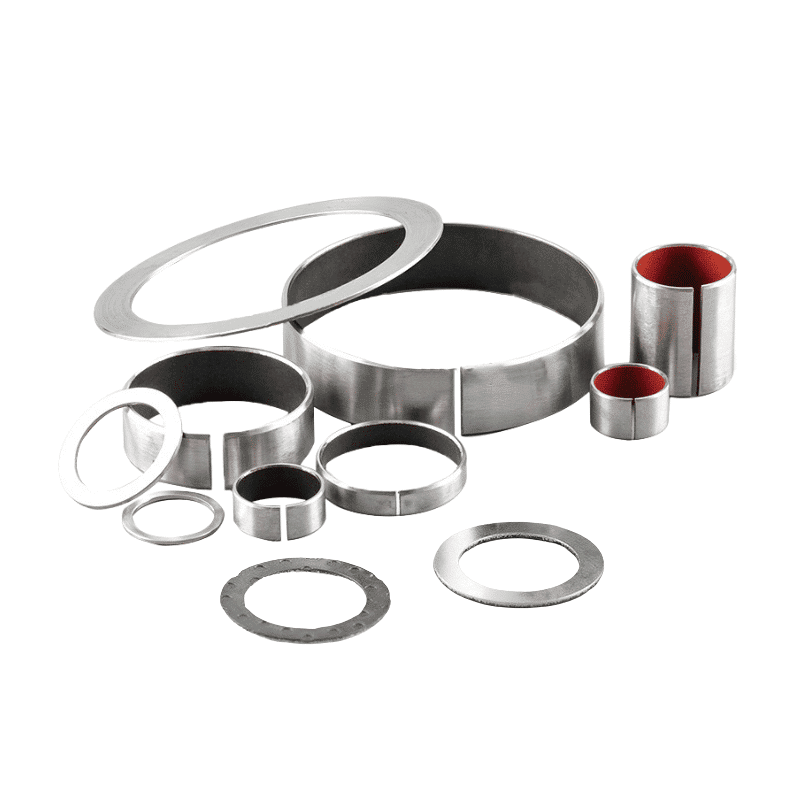

Beyond our standard products, we offer customized bushings to suit unique needs. Our bushings, including Plain Bushes Strip and Sheets, composite bushing strips, bronze plating bushings, and steel-backed bushings, guarantee punctual delivery, reliable supply, and consistently high quality.

Our offering also includes POM Bushes, featuring strips that are maintenance-free with steel backing. These cylindrical plain bushes are a part of our metal-polymer composite plain bearings line-up, exemplifying the high-quality promise we uphold.