tellurium copper

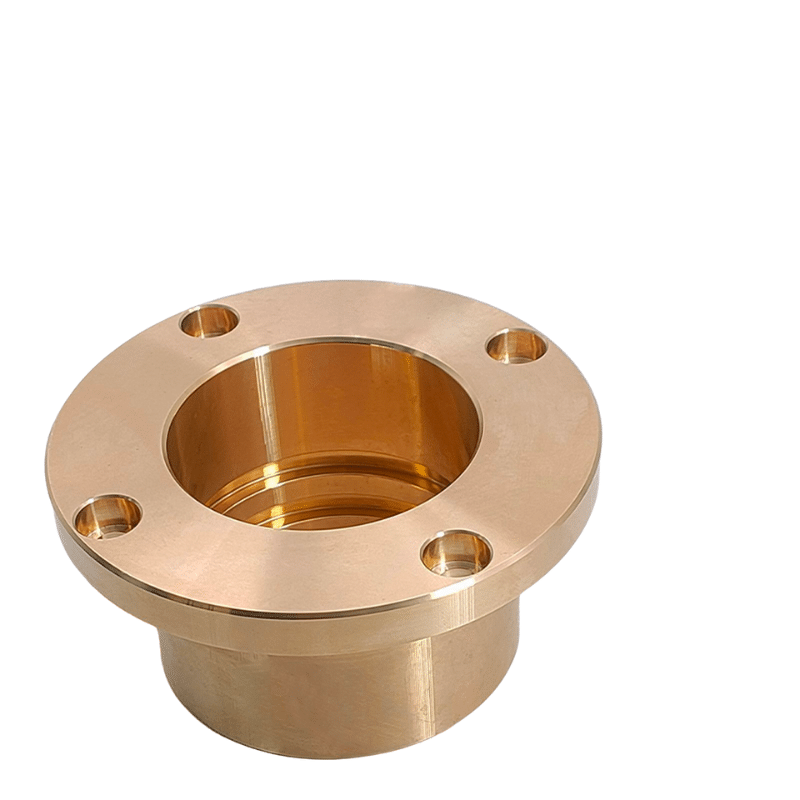

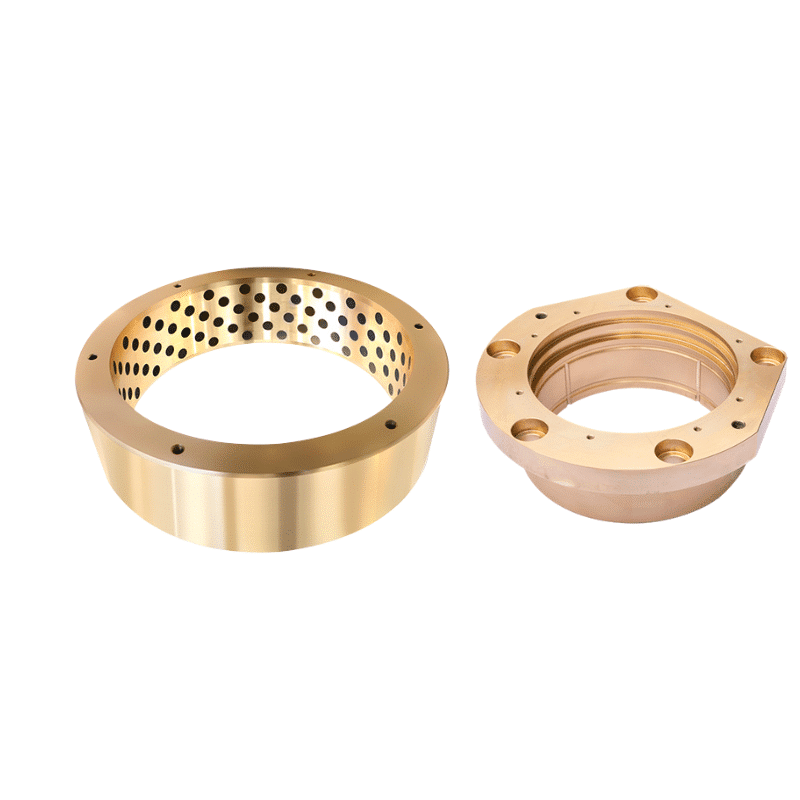

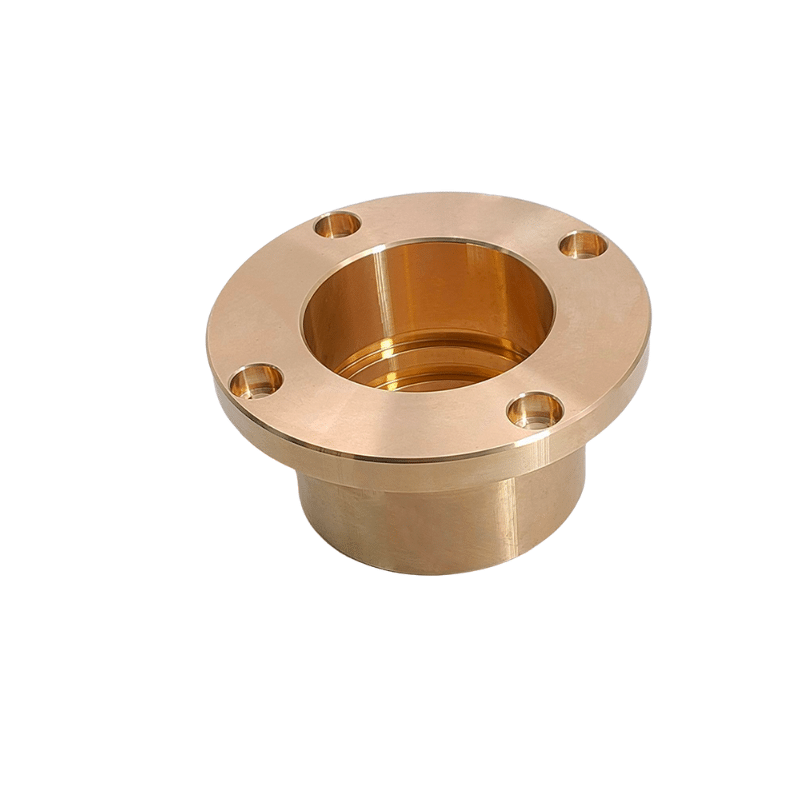

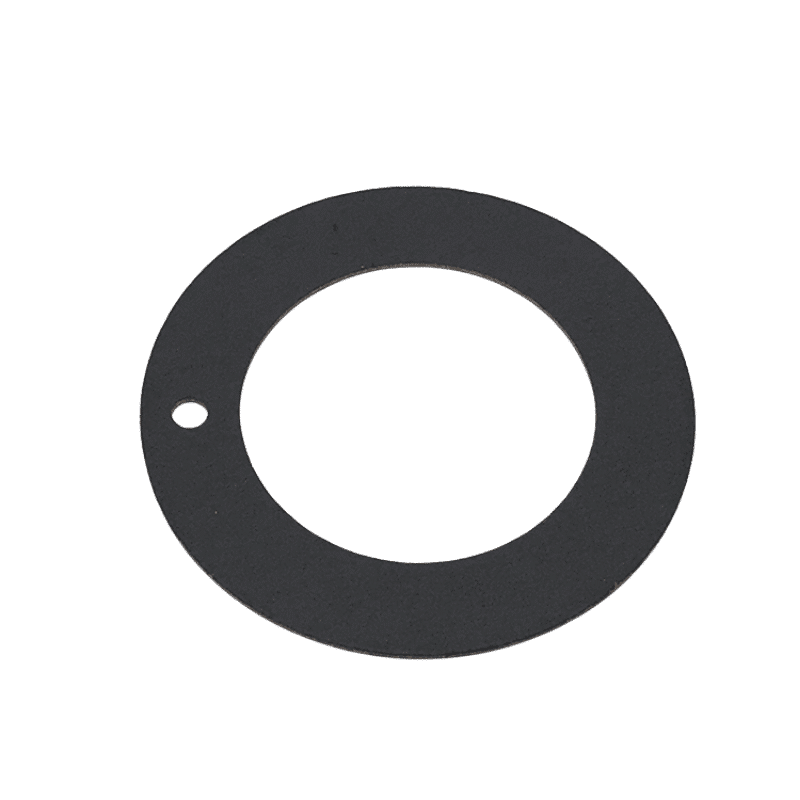

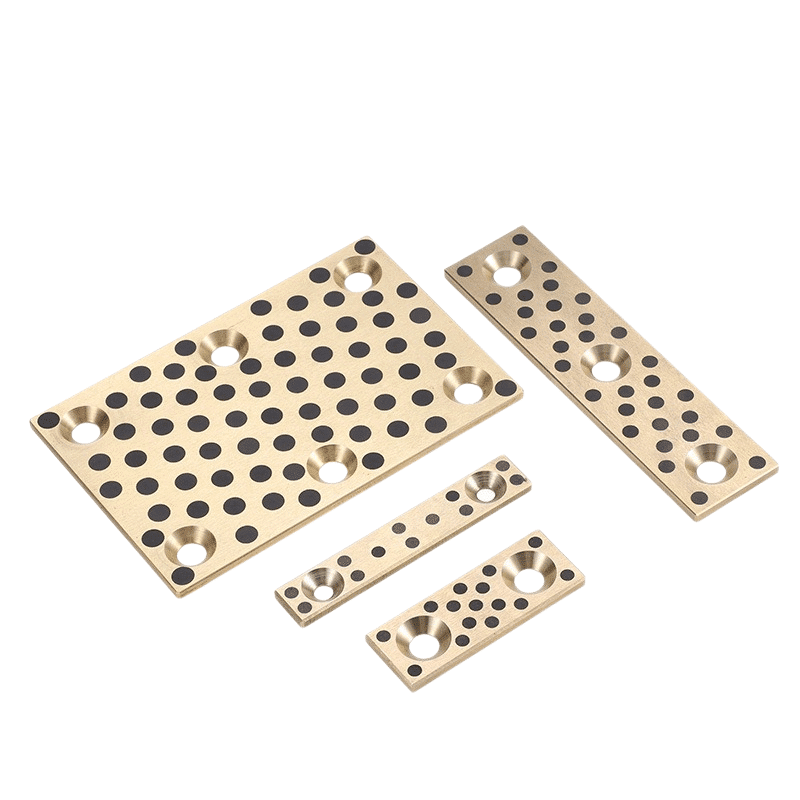

Bearings and Bushings for the Future: Precision and Customization: Our company, in bearing engineering with decades of experience, designs and develops high-precision self-lubricating bronze bearings & plain bushes. We offer a wide array of sliding bearings tailored to meet specific needs. Renowned for our expertise in custom bronze bushing and slide plate solutions, we provide an expansive selection of bushing metal alloys. Contact us today to benefit from unparalleled services at competitive prices.

tellurium copper

The C14500 tellurium copper material is a specialized alloy, combining copper with 0.4-0.7% tellurium to enhance its machining performance. Additionally, there is a variant of this alloy, copper telluride, with an equal 50-50 mix of tellurium and copper, serving as an intermediate alloy.

This material is recognized under various industry standards, including:

- Copper Development Association (CDA) designation: C14500

- American Society for Testing and Materials (ASTM) specifications: B124, B124M, B301, B301M

- Society of Automotive Engineers (SAE) standards: J461, J463

It is also classified under the category of Tellurium-Bearing (PTE) materials.

The chemical composition of C14500 tellurium copper, as per ASTM B301/B301M-13(2020), includes primarily copper (Cu), with specific percentages of phosphorus (P) and tellurium (Te). This composition also accounts for the inclusion of silver and phosphorus within the material.

Similar or Equivalent Specification

| CDA | ASTM | SAE | AMS | Federal | Military | Other |

|---|---|---|---|---|---|---|

| C14500 | B124 B124M B301 B301M |

J461 J463 |

Tellurium-Bearing (PTE) |

Chemical Composition

Cu%1,2 |

P% |

Te% |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Chemical Composition according to ASTM B301/B301M-13(2020)1Includes silver 2Includes tellurium and phosphorus |

|||||||||||

99.90min |

0.004-0.012 |

0.40-0.70 |

|||||||||

Tellurium Copper (UNS C14500), utilized in new energy automotive connectors, is a unique variant of copper known for its enhanced machinability. This improvement is achieved by alloying standard, pure copper with tellurium, which significantly boosts its cutting properties. In addition to its improved machinability, tellurium copper is also distinguished by its high electrical conductivity, making it a suitable material for applications in the automotive sector, particularly in the realm of new energy vehicles.

FIND A PRODUCT

Give us a call to schedule your cast bronze bearing

Centrifugal casting bronze bearing

Our company provides C14500 Tellurium Copper bars, catering to a range of industries. As a manufacturer, we specialize in producing metric-sized cast bronze bushings and bearings. We accommodate small minimum order quantities, leveraging our extensive expertise to ensure short delivery times and cost-effective pricing. Our products are widely used in various sectors, including the automotive industry, machine building, and the electrical industry.

Solutions For Every Industry

Searching for Dependable Bushing Solutions? viiplus Has What You Need.

Design Guides, Materials

Bushing design, Comprehensive design manuals covering a range of self-lubricating materials used in all of viiplus’s manufacturing processes.

Technical Guides

Manufacturing On Demand, Technical Guides For Machining Design. Discover the latest in metal alloys, materials, and design tips for manufacturing custom machined and self-lubricating bearing parts.

Get Instant Quote

To receive your instant quote, simply upload your drawing file and choose your production process & bushing material.

Prototyping, Place Order

After you place your order, we will start the production process. You will receive updates when your order has completed production and is ready to be dispatched.

Receive Your custom Parts

We provide precision-inspected high-quality parts, packing lists and documents, and delivery tracking.