providing factory services of superior quality with focus on efficiency.

01.

Providing Quotes for Custom Parts and Large-Scale Production Orders

02.

Satisfaction guaranteed

03.

Ensuring timely delivery

04.

Revolutionize How You Produce Custom Components

We Stand by Your Side from Initial Prototyping through to Production and Further.

Why select this material ?

- This alloy possesses good hardness, strength, and wear resistance.

- Excellent anti-frictional qualities

- Good casting properties.

- Readily machined, broached, or reamed

Tin Bronze Bearings Application

- Bushings for electric motor, cranes, and draglines

- Track roller bushings for crawler tractors

- Guide bushings for valves

- Main bearings for presses

- Many other wear applications

✔ STANDARD-STOCKED BRONZE BEARINGS

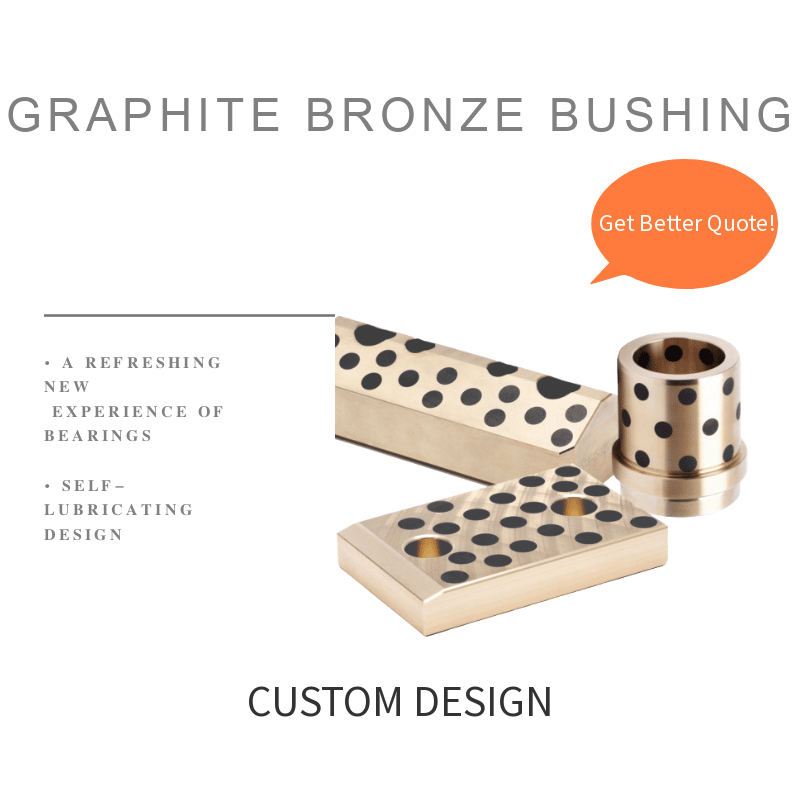

Cast Bronze Bushing & Bearing, Plugged Graphite.

Cast Bronze Bearings Spacer Alloy Leaded Tin Bronze Bushing Metal Graphite

The lead content in high-leaded tin bronze alloys is between 7.00% and 15.00%.

Chemical Composition

| Cu%1 | Pb% | Sn% | Zn% | Fe% | P% | Ni%1,2 | Al% | S% | Sb% | Si% | |

|---|---|---|---|---|---|---|---|---|---|---|---|

|

Chemical Composition according to ASTM B505/B505M-18

|

|||||||||||

| 81.00- 85.00 |

6.00- 8.00 |

6.30- 7.50 |

2.00- 4.00 |

0.20 | 1.50 | 1.00 | 0.005 | 0.08 | 0.35 | 0.005 | |

We precision-craft self-lubricating bronze bearings tailored to your specific designs, delivering Leaded Tin Bronze Bearings that are inherently maintenance-free. These bearings are ingeniously integrated with solid lubricant materials, such as graphite inserts, to ensure continuous lubrication without the need for manual intervention.

Key Features and Benefits:

No Manual Lubrication Required: Eliminate the hassle of regular lubrication – our bearings are designed to self-lubricate, saving you time and effort.

Zero Maintenance: Enjoy a maintenance-free operation, as these bearings are engineered to function seamlessly without the need for regular upkeep.

Ideal for Challenging Applications: Perfectly suited for environments where traditional lubrication methods are impractical or where the use of oil/grease is not feasible.

Optimal for Heavy Loads and Low Speeds: Experience superior performance under high-load conditions and low-speed operations, where our bearings excel.

These bearings are particularly advantageous in applications where manual lubrication is challenging or impractical, and where oil and grease lubricants are unsuitable. They provide exceptional lubrication efficacy under scenarios of significant loads and slower motions.

We are experts in crafting bespoke sliding bushing solutions, leveraging our comprehensive know-how to address your unique needs. Trust us to deliver a tailored sliding bearing solution that meets your specific challenges, ensuring optimal performance and reliability.

Accredited and Focused on Quality

With a variety of processes at your disposal, such as CNC machining, sheet cutting, and injection molding, we stands as your comprehensive solution for custom manufacturing.

Our High Volume Production Service Provides Dedicated Assistance For Custom Manufacturing Endeavors, Accommodating Projects Of Any Complexity And Scale.

▪ Metal Bearing Production Solutions

Your comprehensive answer for production, our team stands as the ideal choice for your manufacturing requirements.

▪ self-lubricating Bearings Solutions

With our technical specialists, the convenience of our secure quotation platform, and extensive global manufacturing capabilities, we are equipped to meet your needs.

Produce custom components as needed

We’re Your Partner From Prototyping to Production and Beyond

We provide a variety of services to assist you in creating functional prototypes and transitioning to production components. Manufacture custom parts as needed, utilizing various materials for self-lubricating bearings. Reach out to us to benefit from our expert applications engineering team’s production capabilities.

Product Quality Index

Energy Generation

Ready to get started on your custom self-lubricating bearing quote?

Breathtaking design for home living.

The variety of materials, cost-effective custom manufacturing per unit, and rapid production pace make it an excellent choice for prototyping.

Nam aliquet ante porta, gravida elit interdum, luctus porta sapien justo, at fringilla felis suscipit vestibulum.