providing factory services of superior quality with focus on efficiency.

01.

Providing Quotes for Custom Parts and Large-Scale Production Orders

02.

Satisfaction guaranteed

03.

Ensuring timely delivery

04.

Revolutionize How You Produce Custom Components

We Stand by Your Side from Initial Prototyping through to Production and Further.

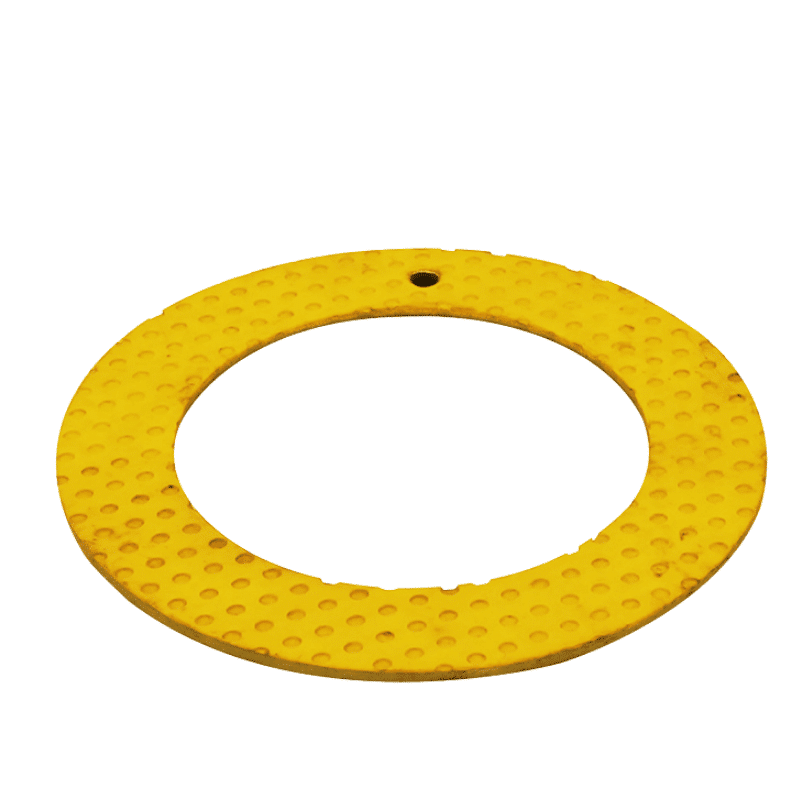

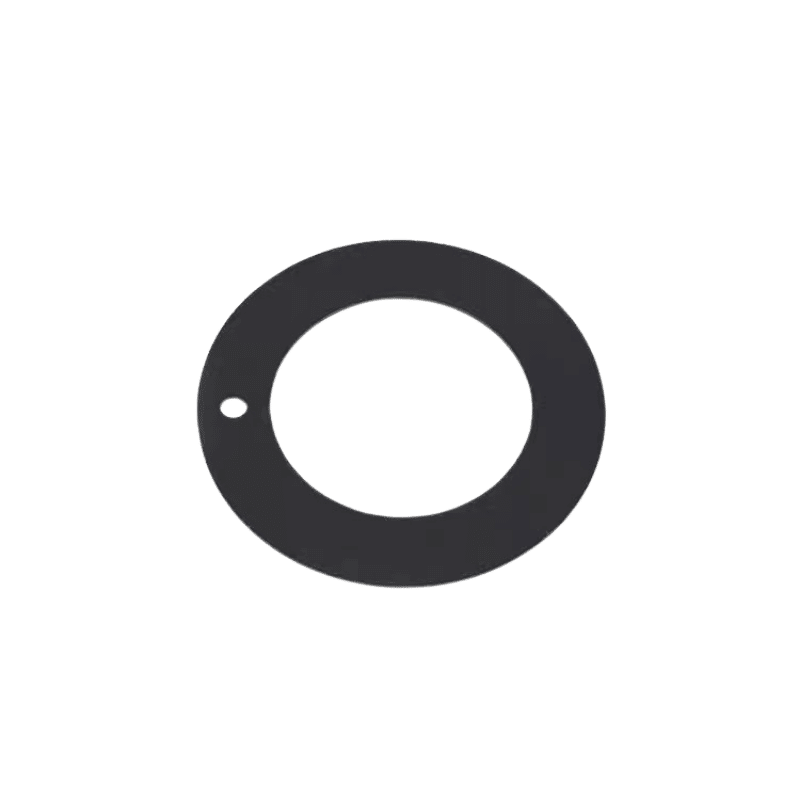

Multi-Layer, 3 layers bearing bushing. Straight & Shouldered size, Purchase Oil Free Bushings, Oil-Free Bushings, and other configurable components! Fast delivery ✓ Fair prices!

A 3-layer composite bushing refers to a type of bushing composed of three layers or components. This design is commonly used in various mechanical and electrical applications to provide insulation, reduce friction, and support rotating or sliding components.

The three layers typically found in a composite bushing are:

- Inner Layer: The innermost layer of the bushing is usually made of a low-friction material such as PTFE (polytetrafluoroethylene) or a similar polymer. This layer allows for smooth movement and reduces friction between the rotating or sliding components.

- Intermediate Layer: The intermediate layer provides structural support and may be made of materials like bronze, steel, or another durable material. This layer helps distribute the load and adds strength to the bushing.

- Outer Layer: The outermost layer of the composite bushing acts as an insulator and protects the inner layers from environmental factors such as moisture, dust, or contaminants. It is typically made of materials like rubber, plastic, or thermoplastic elastomers (TPE) to provide insulation and resist wear.

By combining these three layers, a composite bushing can offer improved performance compared to a single-layer bushing. The low-friction inner layer reduces friction and wear, the intermediate layer provides strength and load distribution, and the outer layer offers insulation and protection.

Composite bushings find applications in various industries, including automotive, aerospace, electronics, and industrial machinery. They are commonly used in bearings, bushings, hinges, and other components that require smooth movement, durability, and insulation.

Accredited and Focused on Quality

With a variety of processes at your disposal, such as CNC machining, sheet cutting, and injection molding, we stands as your comprehensive solution for custom manufacturing.

Our High Volume Production Service Provides Dedicated Assistance For Custom Manufacturing Endeavors, Accommodating Projects Of Any Complexity And Scale.

▪ Metal Bearing Production Solutions

Your comprehensive answer for production, our team stands as the ideal choice for your manufacturing requirements.

▪ self-lubricating Bearings Solutions

With our technical specialists, the convenience of our secure quotation platform, and extensive global manufacturing capabilities, we are equipped to meet your needs.

Produce custom components as needed

We’re Your Partner From Prototyping to Production and Beyond

We provide a variety of services to assist you in creating functional prototypes and transitioning to production components. Manufacture custom parts as needed, utilizing various materials for self-lubricating bearings. Reach out to us to benefit from our expert applications engineering team’s production capabilities.

Product Quality Index

Energy Generation

Ready to get started on your custom self-lubricating bearing quote?

Breathtaking design for home living.

The variety of materials, cost-effective custom manufacturing per unit, and rapid production pace make it an excellent choice for prototyping.

Nam aliquet ante porta, gravida elit interdum, luctus porta sapien justo, at fringilla felis suscipit vestibulum.