self lubricating pom

self lubricating pom

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand

self lubricating pom

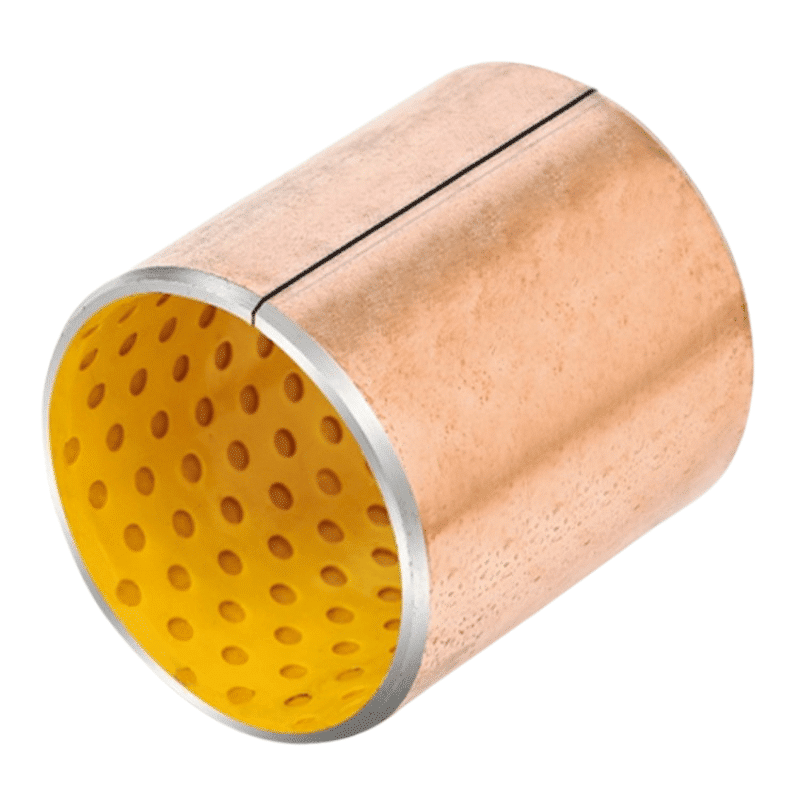

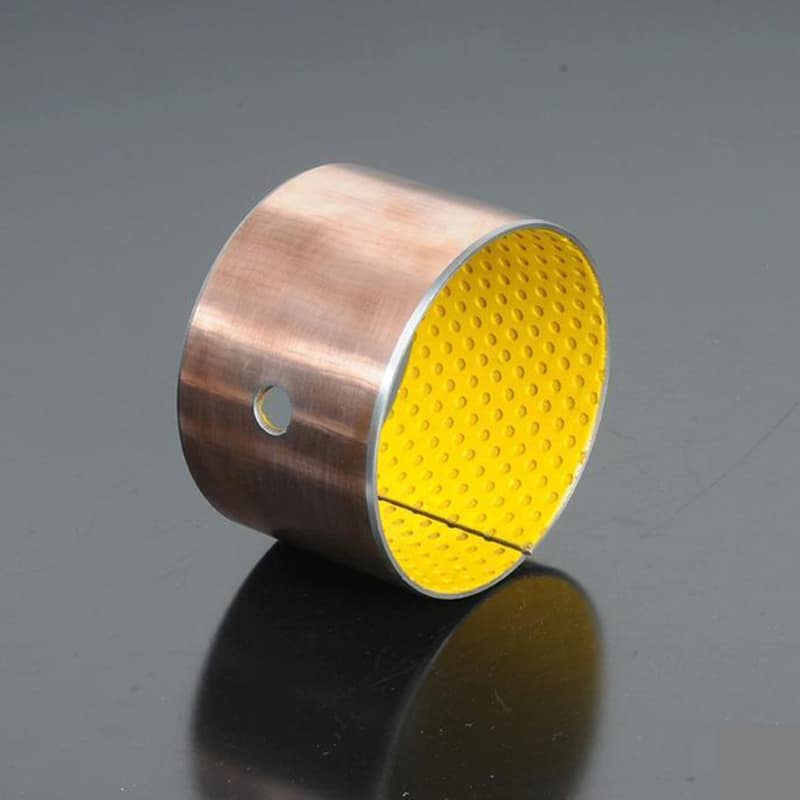

Structure

After the rolling process is completed, POM is filled in interstice of bronze layer, lubrication indents are stamped, which are full of oil grease, which will be removed and transferred on the mating surface, forms a physically lubricating film, which will reduce the friction coe. and protect the mating shaft.

2 Porous bronze layer;

The layer provides bonded strength of self-lubricating. Layer.

3 Steel Backing

The layer provides load & thermal conductivity

4 Copper / Tin layer.

self-lubricating pom bushing, acetal resin bushing.

Self-Lubricating POM Bush: This low-maintenance polymer plain bearing features a marginally lubricated, three-layer composite structure, including cylindrical bushes and thrust washers.

POM layer of carefully sized, bearing quality bronze powder sintered onto the steel backing. This porous bronze inner layer is impregnated with the acetal resin and is securely sintered to the steel. The bronze also serves as an effective heat conductive path which minimizes undue temperature rise at the bearing surface and provides dimensional stability

Self-Lubricating POM Bushings: An Introduction and Their Advantages

Bushings, often referred to as plain bearings, are an integral part of many machines, providing a low friction interface between moving parts. As technology has evolved, so too have the materials used for these bushings. One of the most notable advancements in this field is the development of self-lubricating POM bushings. In this article, we’ll delve into what these bushings are, how they work, and the benefits they offer.

What is a POM Bushing?

POM, or Polyoxymethylene, is a type of thermoplastic material known for its excellent mechanical properties. Also commonly referred to as Acetal or Delrin, POM has become a preferred choice for a variety of engineering applications due to its strength, stiffness, and dimensional stability.

A self-lubricating POM bushing is a type of bushing made from POM that has been imbued with lubricating agents. This design eliminates the need for periodic lubrication, reducing both maintenance time and cost.

How Does Self-Lubrication Work?

The concept behind self-lubricating POM bushings is straightforward. During the manufacturing process, lubricating agents are embedded within the POM material. As the bushing undergoes wear and friction, these lubricating agents are released onto the surface, ensuring a consistent layer of lubrication. This process greatly reduces the coefficient of friction and increases the lifespan of the bushing.

Advantages of Self-Lubricating POM Bushings

- Reduced Maintenance: One of the most significant benefits of self-lubricating bushings is the reduced need for maintenance. Traditional bushings require periodic lubrication to function optimally. With self-lubricating POM bushings, this need is virtually eliminated, leading to reduced downtime and operational costs.

- Extended Lifespan: The continuous release of lubricating agents means that the bushing remains lubricated throughout its life. This reduces wear and tear and, consequently, increases the lifespan of the bushing.

- Environmentally Friendly: Since there’s no need for external lubricants, there’s a reduced risk of environmental contamination. This makes self-lubricating POM bushings a more environmentally friendly choice.

- Consistent Performance: The consistent release of lubricating agents ensures that the bushing’s performance remains optimal over time. This leads to more predictable and reliable machinery operation.

- Cost-Effective: While the initial cost of a self-lubricating POM bushing might be higher than traditional bushings, the reduced maintenance and longer lifespan often lead to cost savings in the long run.

Applications of Self-Lubricating POM Bushings

Self-lubricating POM bushings find applications in a variety of industries, including:

- Automotive: Used in gear selectors, wiper systems, and door hinge mechanisms.

- Industrial machinery: Employed in sliding and rotating applications where consistent performance is crucial.

- Consumer goods: Found in household appliances and electronic devices.

Conclusion

Self-lubricating POM bushings represent a significant advancement in the world of machinery and equipment. With their reduced maintenance needs, extended lifespan, and consistent performance, they offer a compelling alternative to traditional bushings. Whether you’re designing a new piece of equipment or looking to upgrade an existing system, it’s worth considering the many benefits that self-lubricating POM bushings bring to the table.

Materials

They are produced from a material composed of the next three layers:

Marginal lubricating bearing

MaterialCarbon Steel + Copper Powder + POM bushing

The typical applications used in vehicle chassis, forming machine tools, steel metallurgical machinery, mineral mountain machinery, hydraulic industry, and rolling steel industry, etc.

Self-lubricating pom bearing data

| Max. Load Capacity P | ||

| Static Load | N/mm2 | 250 |

| Dynamic Load | N/mm2 | 140 |

| Max. Speed V | ||

| Pre-Lubricated | m/s | 2.0 |

| Oil Grease Lubrication Continuous Operation | m/s | >2 |

| Max. Pv Value | N/mm2 · m/s | 2.8 |

| Coefficient of Friction | μ | 0.05~0.20 |

| Operation Temperature Range | ℃ | -40~110 |

| Thermal Conductivity | W(m · k-1) | 42 |

| Coefficient of Thermal HSB-2pansion | λST | 11·10K-6 |

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally