Metal Polymer Bushings: POM Bushings for Lifting Bearings and Other Applications, POM Composite Bushings, Special & Drawing Parts

Polyoxymethylene (POM) bushings, also known as acetal or delrin bushings, are engineered for superior performance in a wide variety of applications. POM is a high-strength, low-friction engineering plastic that has excellent wear properties in both wet and dry environments. These characteristics make it an excellent choice for use in metal polymer bushings. metal polymer POM bushings offer a combination of high-load capacity, excellent wear resistance, and low friction. These characteristics make them a versatile solution for a wide range of applications in various industries.

Low-maintenance dry sliding bearings dx bush solution

POM composite bushings replace DX bushing are often used in general industrial machinery, heavy machinery, machining facilities, plants and automotive parts.

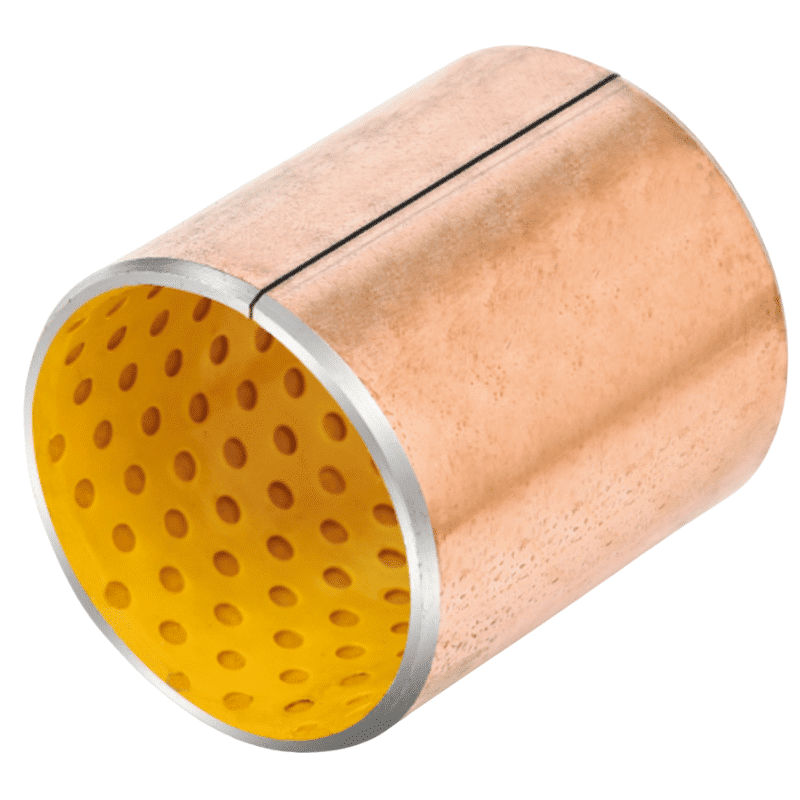

Customized bushing designs. Cylindrical bushes with non-standard. Use Composite bushing material; Suited for dry & Hi Temp Applications. Inquire Online! Highlights: Plain Bearing Experts Available, Lubrication of composite bushing custom size experience! The plain bearing is low-maintenance and consists of three layers: steel, porous bronze and POM resin. The cavities of the metal polymer-acetal resin are real reserves of lubricant, thanks to which the pom within the specified limits is not exposed to defects in alignment and edge overload, and at the same time guarantees heat loss from the bearing working surface.

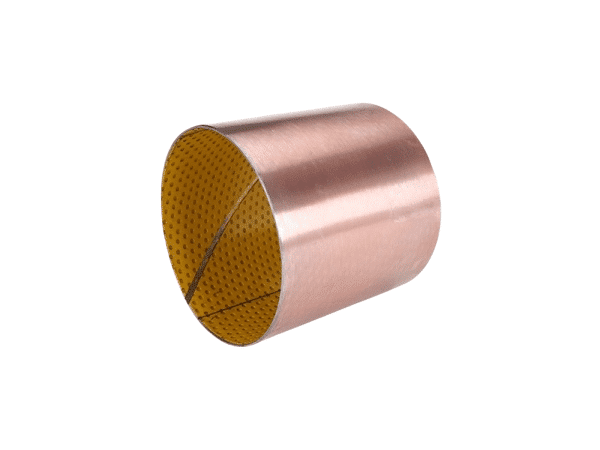

Wrapped composite sliding bearing, steel/acetal resin (POM), lubrication pockets, low-maintenance Available for orderBearing sleeves

about the company

Composite Bushing Low-maintenance with lubrication pockets

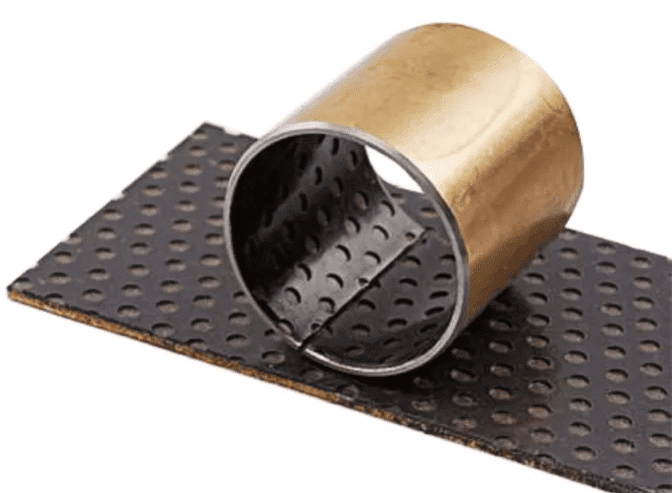

Porous bronze layer sintered on a steel backing with the function of bonding the sliding surface in a polyacetal resin. Porous bronze layer sintered on a steel backing with the function of bonding the sliding surface in a polyacetal resin and allowing thermal dispersion, resulting in a socket that collects and gradually releases lubricant. lubricant to reduce friction and protect the surface. To facilitate relubrication, the composite bearing bushings have an external hole for this purpose. It is recommended to use greases containing lithium soap; conversely. MoS2 and graphite-based greases are not suitable. Composite bearing bushings are used in a number of applications, including Among them we find: mining and metallurgy, printing presses, hydroelectric generators and cold rolled steel; typically applications with periodic lubrication. Steel; typically a regularly lubricated application. The use of this type of bushing is growing rapidly, thanks to its The main features are as follows, which facilitate the elimination of various problems.Characteristics

Product Quality Index

Energy Generation

Composite Bearing Bushing Advantages.

Beautifully crafted leather products.

- Low maintenance costs due to long intervals between relubrication.

- Good adaptation to oscillating and rotating movements.

- Limited wear (if applied and used correctly).

- Water repellency.

- Reduced sensitivity to edge loading.

- Good thermal dispersion.

We manufacturing composite bearing bushing tailored to your individual needs.

What is a composite bearing bushing?

A composite bearing bushing is a bushing consisting primarily of steel, porous bronze and a PTFE frame. It is used to allow oscillation, rotation and sliding on the bearing. It is also used to absorb and transmit radial forces. These are mainly installed in vehicles, agricultural machinery, textile machinery, printing machinery, etc.

Composite plain bearings are mainly used for bearing arrangements with heavy loads must be supported and where rotational or the swinging movements are relatively slow. Due to their good sliding properties and compact design, these plain bearings are particularly suitable for bearing arrangements where is it! The standard range of slide composite plain bearings is very comprehensive and covers almost every standard size.

Features

High Load, Low Speed: POM bushings are suitable for high loads and low speeds. They are designed to endure heavy-duty loads and are particularly useful in industrial and heavy machinery applications, where they can perform under pressure yet still deliver smooth and efficient operation.

Grease Retention: The sliding layer of the POM bushings has been manufactured with indents designed for grease retention. This allows for the effective capture and retention of lubricant, ensuring continuous lubrication during operation, and contributing to the durability and longevity of the bushing.

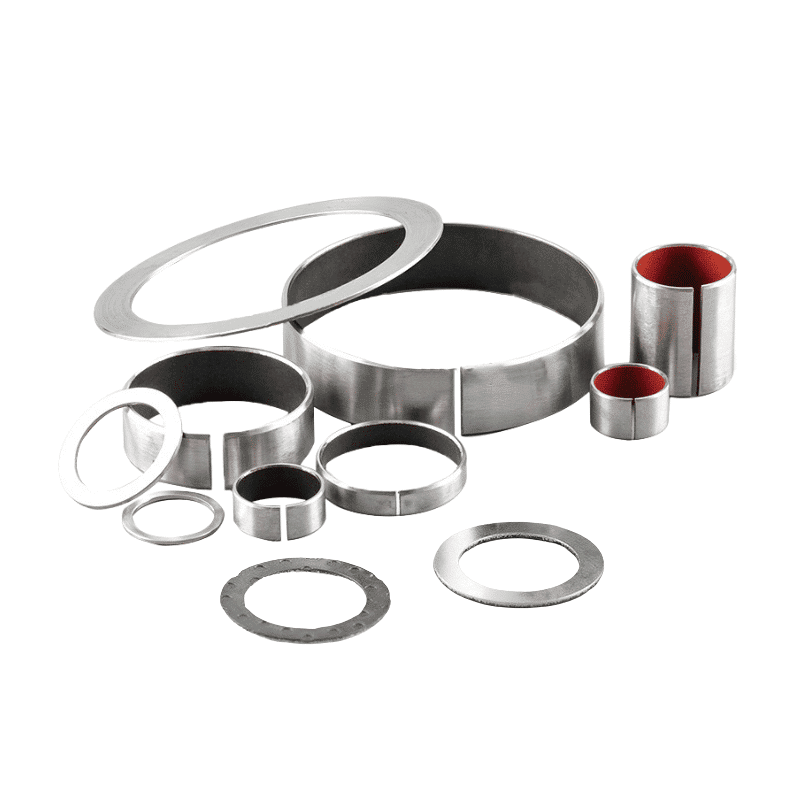

Versatile Design Options: POM bushings are available in a variety of forms to suit different applications, including cylindrical bushes, flanged bushes, thrust washers, and sliding plates. This makes them suitable for a wide range of uses in various industries.

Wear Resistance: These bushings have excellent wear resistance, minimizing shaft wear and improving the operational lifespan of the machinery in which they are installed. This results in long-term cost savings and reduced maintenance requirements.

Low Friction: POM bushings perform exceptionally well in conditions where lubrication is present, providing low friction for smooth and efficient operation.

What are the different types of composite bearing bushings?

There are a number of plain bushings and flanged composite bearing sizes that conform to current standards.

For composite bearing type plain bushings, they have a longitudinal groove to facilitate assembly. You can distinguish two types of materials. The first type of material is steel-backed with PTFE composite bearings. This type of bushing is used for dry applications that do not require lubrication and maintenance. The second type of material is steel-backed with POM composite bearings. This type is used for applications that require low maintenance lubrication.

The composite bearing bushing materials

The composite bearing bushing common materials are: PTFE line composite bearing : This is one of the most widely used materials. As mentioned above, it does not require maintenance and can be used dry. It can also be used in contact with liquid lubricants. However, the use of grease is not recommended for this type of material. It is also important to know that it contains lead. It should not be used in the food industry.

Bronze backed PTFE line bushing composite bearing : This material has the same characteristics as the steel backed ptfe lined bushing announced above. The main difference is that the metal matrix is different. Bronze backed is also more expensive.

The stainless steel backed ptfe line bushing composite bearing material is not used in water and is resistant to corrosion and is often used in light and marine environments.

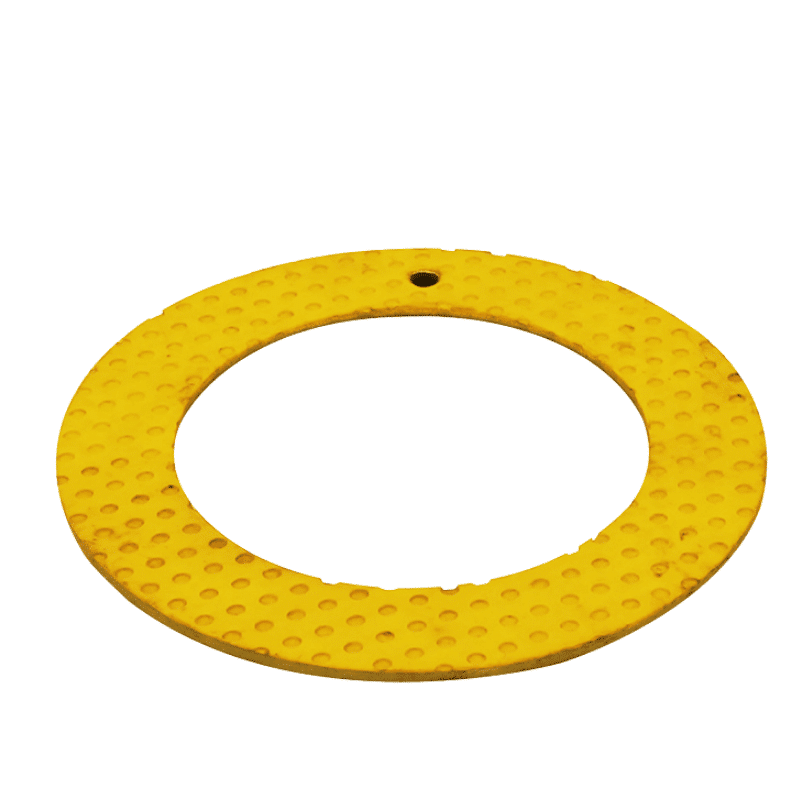

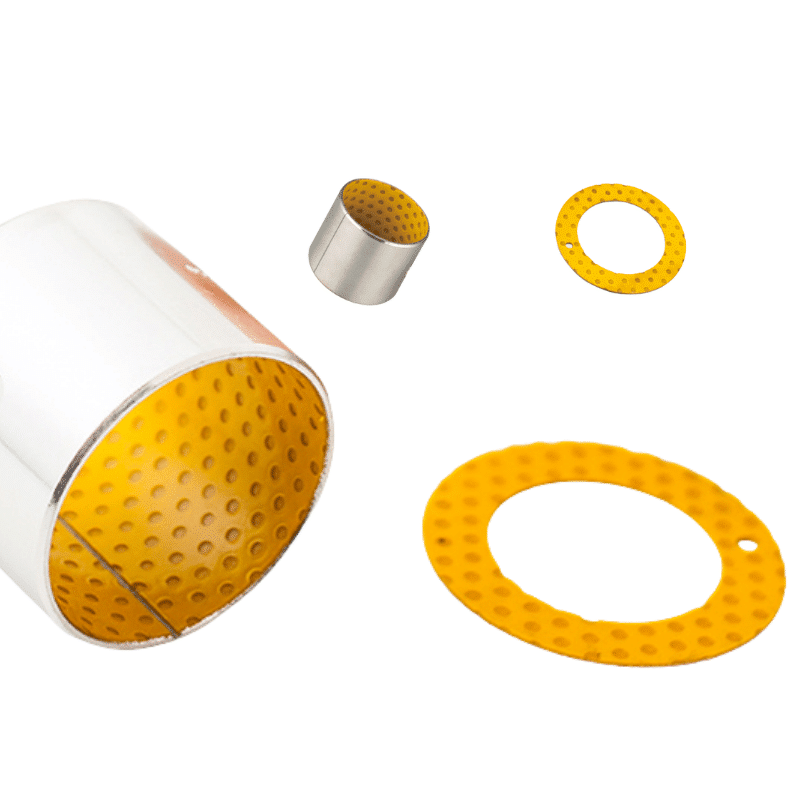

POM composite bearing bushings: This material is used in applications that require liquid or grease lubrication and low maintenance. Therefore, this class of rings has a lubrication hole and an inner diameter with a honeycomb-like surface. This material contains lead and therefore cannot come into contact with food.

How do I choose a composite bearing bushing?

In order to choose the product you need, it is necessary to know its dimensions. In fact, you need to know its inner diameter, outer diameter and length. Or then flange composite bearing size, composite bearing wall thickness, it is equally important to know in what environment the ring will be installed and what are the limitations. For example, if you know that your ring will be in contact with food, then you should focus your search on self-lubricating materials for stainless steel video grade composite bearings. If you find the size you need on our website but the material you want is not available, contact us to recommend the right type of composite bearing for you.

Find your composite bearing: We offer a large selection of quality parts, including plain composite bearing bushings, to meet your needs and limitations. You can search by filtering through different basic criteria in order to find something that fits both your budget and your assembly requirements Thanks to our large inventory, we offer fast delivery times. If you have questions and need specific information to place an order, our sales department will be happy to help you. With smaller starting order quantities, specializing in custom composite bearing bushings for small and micro businesses, our customers can contact us via email or phone.

Applications

Metal polymer POM bushings are commonly used in a variety of industrial applications. They are particularly well-suited to lifting bearings, where their high-load capacity and low-speed performance characteristics provide an effective solution. Other applications include:

Automotive: POM bushings are used in various parts of an automobile including suspension and steering systems, gear mechanisms, and connectors.

Machinery and Equipment: POM bushings are often used in mechanical equipment such as conveyor systems, production line machinery, and in other similar applications where high load-bearing capacity and low friction are required.

Electronics: These bushings are used in electronic devices such as printers, photocopiers, and other office equipment where their low friction and good wear resistance are beneficial.

Composite Bearings & Solutions

Metal POM Bushing Supplier

The POM composite bushing portfolio includes sleeve bushes, and flange size as well as thrust washer and plain bearing solutions for a large number of industrial applications. bushings catalog : composite bushing low-maintenance steel backing and with lubrication pockets. Metric Size straight bushings of triple-layer POM composite material.

- Dry Film Lubricant Coating Dry Film Coating

- Provides solid lubrication of parts subject to torque or contact stresses:

- For maximum fatigue life

- Improved surface properties

- Excellent load carrying capacity

- Provides intermittent dry lubrication

Top Quality

Maintenance-free and low-maintenance POM composite bushing, metal-polymer composite plain bearings competitive edge in technology ensure reliability and safety in the application of our products.

Cost-effective & durable:

metal-polymer composite

pom bushing & plain bearings are a cost-effective alternative for many industrial

and automotive applications.

Custom sleeve bushing solutions for your engineering needs.

POM Bushing, Steel Backed POM Washer Factory – Bronze Thrust Bearing Factory

Brass, Bronze & Copper POM Bushings Supplier

Self-lubricating washer supplier, Reliable Bronze Bushings Manufacturer

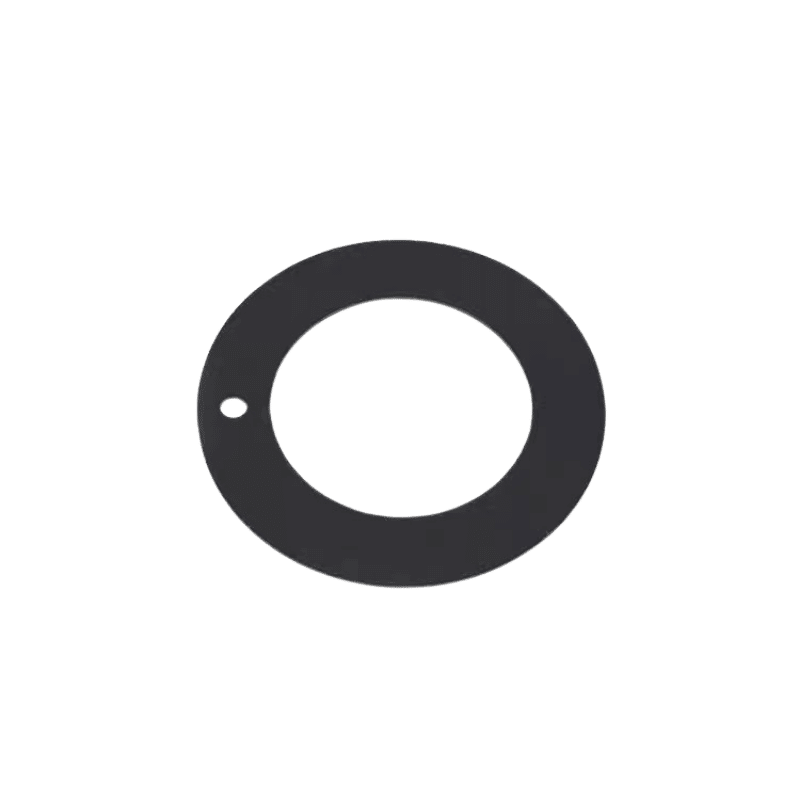

Thrust Washer material very good wear and low friction performance over a wide range of loads, speeds…

Oil Free Parts Selection

Metal-Polymer Plain Bearings Grease Lubricated

Cylindrical Sliding Bushings – Bushings -bronzelube.com

High quality Metal-Polymer Composite Bearing With POM Material Bush from China

Marginally lubricated bearing – Custom Design: Made of steel-bronze-plastic composite, manufactured according to DIN ISO 3547, for oil and grease lubrication, ready-to-install. Available as cylinder liner, thrust washer, sliding strip and as a special part. Metric bearings and imperial bushings made to order: standard bushing forms in special dimensions, half-bushings, special shapes obtained by stamping, bearings with locating notches, lubricant holes and machined grooves, customized bushing designs.

Lubricating composite pom bushings are suitable:

- In case of heavy, swinging and rotating loads

- In case of intermittent work

- If a low coefficient of friction and reduced wear are required

- If you need to check the number of maintenance interventions

Pom Composite Bushing

Maintenance-free, POM lined composite bushing with steel or bronze backing. Price & Delivery Time On Request.

Grease-lubricated composite bushes,Steel/Acetal : Resin (Pom), Lubrication Pockets, Low-Maintenance. Save your purchasing Wrapped composite sliding bearing, steel/acetal resin (POM), lubrication pockets, low-maintenance budget for your project.

- Straight bushes

- Collar bushes

- Thrust washers

Custom Design

The promise of composite bushings high quality, meet your requirement. Always tested. Always proven. Global website www.bronzelube.com

Composite Bushes Order

Small minimum order value & quantity, fast delivery. Use Composite bushing material; Suited for dry & Hi Temp Applications. Inquire Online!

Metal-Polymer Plain Bearings Grease Lubricated, Bushings with Indents

What is composite bearing ?

marginally lubricated bushings for grease or oil lubricated applications; Standard parts contain grease indents in the sliding layer; plain sliding layer: Composite bearing is a kind of oil-free lubrication bearing, the product is based on high quality low carbon steel backing, surface sintering lead-tin bronze alloy, composite bearing by several times high temperature sintering and dense rolling of copper, steel backed.

Metal-Polymer Bearings Composite Self-Lubricating Bushings

Always self-lubricating, always long life.

Cylindrical plain bearing- POM bushing Series

Request A Personalized Quote

Pre-Lubricated Metric POM Cylindrical Bushing: Availability and Applications

Polyoxymethylene (POM), also known as acetal, polyacetal, and polyformaldehyde, is a high-performance engineering plastic used in the manufacture of precision parts that require high stiffness, low friction, and excellent dimensional stability. One such application of POM is in the production of pre-lubricated cylindrical bushings, which are used in a range of mechanical applications due to their durability and efficient performance.

Availability

Pre-lubricated metric POM cylindrical bushings are available in a variety of standard dimensions. These bushings are produced in a range of forms to meet a variety of industrial and mechanical requirements. The following are the most commonly available forms:

-

Cylindrical Bushes/Split Bushings: These are the simplest form of bearing, comprising a single piece of material, either a complete cylinder or split for ease of installation. They are used in a wide variety of applications and are often self-lubricating.

-

Thrust Washers: These are flat plates used to prevent movement along the axis of a shaft. The thrust washer bears the axial load, helping to reduce friction and wear on the machinery.

-

Sliding Plates: These are used where a component needs to slide with minimal friction. The sliding plate provides a smooth, hard surface that can bear a load while reducing friction and wear.

In addition to these standard forms, POM cylindrical bushings can also be custom-made in both metric and imperial dimensions, accommodating the unique requirements of various applications.

Applications

Pre-lubricated POM cylindrical bushings are commonly used across a wide array of industries, including but not limited to automotive, aerospace, electronics, and machinery manufacturing. Some of their key applications include:

- Gearbox assemblies

- Pivot points

- Linkage mechanisms

- Steering systems

- Suspension systems

These bushings are especially beneficial in situations that demand high stiffness, low friction, excellent wear properties, and significant dimensional stability.

Pre-lubricated metric POM cylindrical bushings offer a high-performance solution for a range of mechanical applications. Their durability, efficiency, and availability in a variety of forms make them a preferred choice in a multitude of industries.

POM Cylindrical Bushings: An Optimal Solution for High-Performance Applications

Polyoxymethylene (POM), also known as acetal, polyacetal, and polyformaldehyde, is a high-performance engineering polymer. POM cylindrical bushings exhibit superior mechanical properties, including high strength, hardness, and rigidity over a wide range of temperatures and humidity.

What is POM?

POM is a semi-crystalline engineering thermoplastic characterized by its high strength, low friction, excellent dimensional stability, and resistance to many chemicals and solvents. Due to its excellent sliding properties and wear resistance, POM is often used in manufacturing precision parts requiring high stiffness, low friction, and dimensional stability.

POM Cylindrical Bushings

POM cylindrical bushings are an excellent choice for various mechanical and industrial applications due to their remarkable properties. Here are some distinguishing features of POM bushings:

-

Low Friction: POM offers low friction coefficient which helps in enhancing the performance of machinery by reducing friction-related losses. This makes POM bushings ideal for applications requiring high-speed movement.

-

High Strength and Rigidity: POM has excellent strength and rigidity, making these bushings highly durable and resistant to deformation under load.

-

Excellent Wear Resistance: POM bushings exhibit excellent wear resistance, which contributes to a longer lifespan of the machinery parts and lower maintenance requirements.

-

Good Chemical Resistance: POM bushings are resistant to many solvents, oils, and other chemicals, which makes them suitable for use in harsh environments.

-

Wide Operating Temperature Range: POM maintains its properties over a wide temperature range, making these bushings suitable for use in various environments and applications.

Applications of POM Cylindrical Bushings

POM cylindrical bushings are widely used in many industries due to their versatile properties. They are found in automotive applications, industrial machinery, home appliances, electronic parts, and many more. In these applications, POM bushings offer reliable and efficient performance, contributing to the overall productivity and efficiency of the systems in which they are used.

POM cylindrical bushings provide an optimal solution for applications requiring a high-performance, reliable, and cost-effective bearing. Their unique combination of properties makes them an excellent choice for a wide range of industrial applications.

Metal-Polymer Composite Bearings: The New Era of Oil-Free Lubrication Bearings

Metal-polymer composite bearings represent a significant evolution in bearing technology, offering an oil-free, high-performance solution particularly well-suited to demanding applications. These bearings consist of a low carbon steel backing, onto which a lead-tin bronze alloy is sintered multiple times at high temperatures and compacted to form a seamless copper-steel bimetallic strip. This innovative design confers numerous benefits, including high load-bearing capacity, impact resistance, high-temperature tolerance, and a unique self-lubricating capability.

Unmatched Performance and Versatility

One of the greatest strengths of metal-polymer composite bearings is their adaptability. The chemical composition of the inner alloy layer can be altered to cater to different bearing pressures, operating temperatures, and sliding speeds. Additionally, the configuration of the oil groove and oil cavity on the friction surface can be customized to suit various lubrication methods, thereby reducing the risk of shaft bite, a common issue in many industrial applications.

These bearings are also robust against environmental challenges, showing exceptional resistance to water, acid corrosion, and erosion. This resilience is particularly beneficial in heavy-duty, low-speed, high-load applications, where traditional lubrication methods struggle to maintain a consistent oil film.

Superior Wear Resistance and Precision

Another significant advantage of metal-polymer composite bearings is their superior wear resistance. They are particularly useful in medium-speed, medium-load, and low-speed, high-load situations. The utilization of low carbon steel as the substrate ensures the outer diameter processing accuracy of the bushing.

Once installed into the seat hole, the bearings don’t require screw fixing; instead, they rely on interference fit, thereby preventing any out-of-round occurrences. The ability to design and incorporate various oil grooves, oil cavities, and oil holes on the friction surface helps these bearings to adapt to different lubrication conditions.

Broad Range of Applications

Metal-polymer composite bearings are suitable for a wide array of applications. They are commonly found in heavy-duty vehicle balance axle bushings and gaskets; automobile engines and chassis; motorcycle clutches; gear pump internals; and lifting equipment, among others.

Their versatility and durability make these composite bearings a cost-effective solution, particularly for applications where traditional lubrication methods are impractical or insufficient.

In summary, metal-polymer composite bearings represent an important development in bearing technology. Their high performance, durability, and versatility make them a go-to choice for a broad range of industrial applications, heralding a new era of oil-free lubrication bearings.

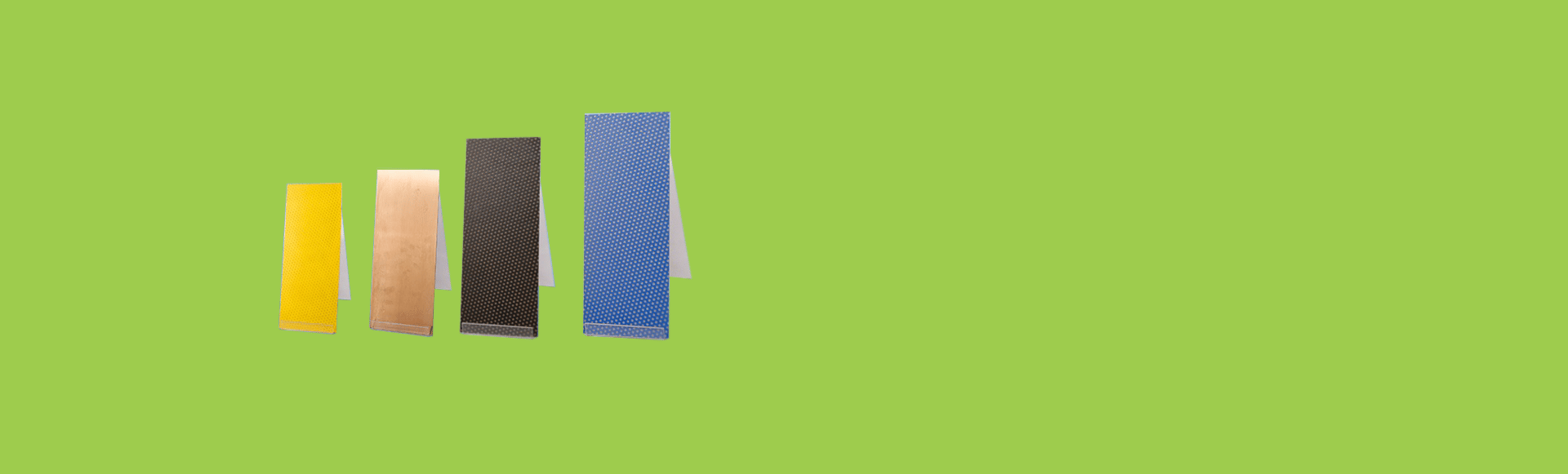

Wrapped sliding bearing, wrapped bushing, steel backed bushing /POM sliding layer, DIN 1494/ISO 3547, Low-maintenance

Wrapped sliding bearing, Wrapped bushing, steel backed bushing /POM sliding can choose different matrix materials according to different working conditions, such as: bronze substrate, stainless steel substrate, and “lead-free” formula products. Environmental protection leads free bushing series, color is orange, orange, blue POM composite.

Non-lead boundary lubrication bearing is improved on the basis of pom bushing. It can be applied to the field where non-lead is required. Now it’s widely used in textile machines, auto operating parts, and other middle speed, middle load, and grease lubrication occasions.

Product pom composite bushings introduction

POM COMPOSITE BUSHING is a lead-free self-lubricating product with boundary made of carbon steel substrate, bronze powder, modified pom and other lubricant materials by special process, which has the characteristics of environmental protection. It not only has a certain chemical properties, at the same time, it has good physical properties and mechanical properties, can be used in all kinds of low speed load, sliding, rotation, swing, and instead of the traditional bearing linear reciprocating motion parts, because of wearing layer surface with oil holes facilitate assembly before daub grease, work with low coefficient of friction, breaking-in performance is good, wear resistance, etc.

Sliding layer POM (MoS2)/ lubrication pockets

Chemical properties: The surface polymer is resistant to chemical corrosion, so its corrosion resistance mainly depends on the steel back and the surface plating. Copper or tin plating on steel back surface can effectively prevent atmospheric corrosion; If working in corrosive medium, steel back can be galvanized, etc.

BRONZELUBE.COM is one of the entities specialized in the production of self-embellishment bearings, sliding bearings, composite bearings, oil-free bearings, dry bearings and maintenance-free bearings in China. Its product quality and performance have reached the level of foreign counterparts.

CHARACTERISTICS

DESCRIPTION

POM bearing

Our range of POM wrapped acetal lined bearings are suitable for rotary and oscillating movement applications. They benefit from long re-lubrication intervals, no absorption of water, outstanding damping behaviors and have a low suceptibility to edge loading.

Our POM range are ideal for the automotive, machine building and agricultural industries and indeed any application where lubricant cannot be supplied continuously.

Just a few examples of where our POM range is used:

Rear chassis hinges

Articulation joints

Spindles of drills

Gearboxes & clutches

Grinding and milling machines

POM bushes wrapped acetal bearings are comparable with PM DX, PCM M, EGB E40, EGB E50 en PAP P20.

- Type

- cylindrical

- Material

- POM

- Length

- Min.: 12 mm (0.47 in)

Max.: 30 mm (1.18 in)

- Inside diameter

- Min.: 8 mm (0.31 in)

Max.: 20 mm (0.79 in)

Customized For Quick Learning

MATERIALS

- Support material Steel backed bearings copper-plated or tin-plated

- Intermediate layer Sintered bronze

- Sliding layerPOM (MoS2)/lubrication pockets

Structure

1 Self-lubricating bearings Layer POM 0.3-0.5mm.

After rolling process completed, POM are filled in intersice of bronze layer, lubrication indents are stamped, which are full of oil grease, which will be removed and transferred on the mating surface, forms a physically lubricating film, which will reduced the firction coe. and protect the mating shaft.

2 Porous bronze layer;

The layer provides bonded strength of self-lubricating Layer.

3 Steel Backed bearings

The layer provides load & thermal conductivity

4 Copper / Tin layer bushings.

| Max. Load Capacity P | ||

| Static Load | N/mm2 | 250 |

| Dynamic Load | N/mm2 | 140 |

| Max. Speed V | ||

| Pre-Lubricated | m/s | 2.0 |

| Oil Grease Lubrication Continuous Operation | m/s | >2 |

| Max. Pv Value | N/mm2 · m/s | 2.8 |

| Coefficient of Friction | μ | 0.05~0.20 |

| Operation Temperature Range | ℃ | -40~110 |

| Thermal Conductivity | W(m · k-1) | 42 |

| Coefficient of Thermal HSB-2pansion | λST | 11·10K-6 |

MAINTENANCE COMPOSITE BEARINGS

POM Composite Bearings is a low self-lubricating bearing material with MoS2 sliding layer and lubrication pockets.

Composite bushing is often used in cranes, truck cranes, tail gates, container equipment and agricultural machinery and construction machines.

Housing ØH7

Bushing inner-Ø after mounting

in the range of D Shaft tolerance h8

Composite Bushing Industry

Bushing assembly, balancing sleeve, brake clamp, steering kingpin axle sleeve and truck tail plate axle sleeve, haulage truck, crane, truck crane, forest machinery, packaging machinery, construction machinery, hydraulic motor, agricultural machinery, mining machinery, metallurgical machinery, hydraulic machinery, steam truck, steel rolling industry, etc.

The composite bushings are made from a steel backed bushing, in which MoS2 is sintered on the surface, using an intermediate layer of bronze powder as a binding agent. These raw material slabs are then cut into a rectangular shape, then wrapped and calibrated to the right size.

Composite Bushing Application

Wrapped sliding bearing, wrapped bushing, steel backed POM (MoS2)/lubrication pockets, DIN 1494/ISO 3547, Low-maintenance used in cranes, truck cranes, tail gates, port equipment and agricultural machinery and construction machines.

composite pom bushing is a Low-maintenance bearing material with MoS2 sliding layer and lubrication pockets. An initial greasing during installation is necessary, after that, periodic greasing with oil or grease is mandatory.

Bushing size chart bushings catalog

Search Bushing Size Chart. Get The Best of the price of bushing parts,

Du, Dx Bushings Catalog – Search Du, Dx Bushings Catalog, Split Type

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

wrapped composite sliding bearing, steel/acetal resin (POM), lubrication pockets, low-maintenance

MATERIALS

Support material Intermediate layer Sliding layer Steel copper plated / tinplated Sintered bronze Acetal resin / POM

Dx Bushings Catalog – Search Dx Bushings Catalog

CAD DRAWINGS

Get access to dx bushing equivalent drawings

| PM0808DX | 8 | 10 | 8 | H7 | h8 | 8.105 | 8.04 | 0.127 | 0.04 | |

| PM0810DX | 8 | 10 | 10 | H7 | h8 | 8.105 | 8.04 | 0.127 | 0.04 | |

| PM0812DX | 8 | 10 | 12 | H7 | h8 | 8.105 | 8.04 | 0.127 | 0.04 | |

| PM1010DX | 10 | 12 | 10 | H7 | h8 | 10.108 | 10.04 | 0.13 | 0.04 | 3 |

| PM1012DX | 10 | 12 | 12 | H7 | h8 | 10.108 | 10.04 | 0.13 | 0.04 | 4 |

| PM1015DX | 10 | 12 | 15 | H7 | h8 | 10.108 | 10.04 | 0.13 | 0.04 | 4 |

| PM1020DX | 10 | 12 | 20 | H7 | h8 | 10.108 | 10.04 | 0.13 | 0.04 | 4 |

| PM1210DX | 12 | 14 | 10 | H7 | h8 | 12.108 | 12.04 | 0.135 | 0.04 | 3 |

| PM1212DX | 12 | 14 | 12 | H7 | h8 | 12.108 | 12.04 | 0.135 | 0.04 | 4 |

| PM1215DX | 12 | 14 | 15 | H7 | h8 | 12.108 | 12.04 | 0.135 | 0.04 | 4 |

| PM1220DX | 12 | 14 | 20 | H7 | h8 | 12.108 | 12.04 | 0.135 | 0.04 | 4 |

| PM1225DX | 12 | 14 | 25 | H7 | h8 | 12.108 | 12.04 | 0.135 | 0.04 | 4 |

| PM1415DX | 14 | 16 | 15 | H7 | h8 | 14.108 | 14.04 | 0.135 | 0.04 | 4 |

| PM1420DX | 14 | 16 | 20 | H7 | h8 | 14.108 | 14.04 | 0.135 | 0.04 | 4 |

| PM1425DX | 14 | 16 | 25 | H7 | h8 | 14.108 | 14.04 | 0.135 | 0.04 | 4 |

| PM1510DX | 15 | 17 | 10 | H7 | h8 | 15.108 | 15.04 | 0.135 | 0.04 | 3 |

| PM1512DX | 15 | 17 | 12 | H7 | h8 | 15.108 | 15.04 | 0.135 | 0.04 | 4 |

| PM1515DX | 15 | 17 | 15 | H7 | h8 | 15.108 | 15.04 | 0.135 | 0.04 | 4 |

| PM1525DX | 15 | 17 | 25 | H7 | h8 | 15.108 | 15.04 | 0.135 | 0.04 | 4 |

| PM1615DX | 16 | 18 | 15 | H7 | h8 | 16.108 | 16.04 | 0.135 | 0.04 | 4 |