providing factory services of superior quality with focus on efficiency.

01.

Providing Quotes for Custom Parts and Large-Scale Production Orders

02.

Satisfaction guaranteed

03.

Ensuring timely delivery

04.

Revolutionize How You Produce Custom Components

We Stand by Your Side from Initial Prototyping through to Production and Further.

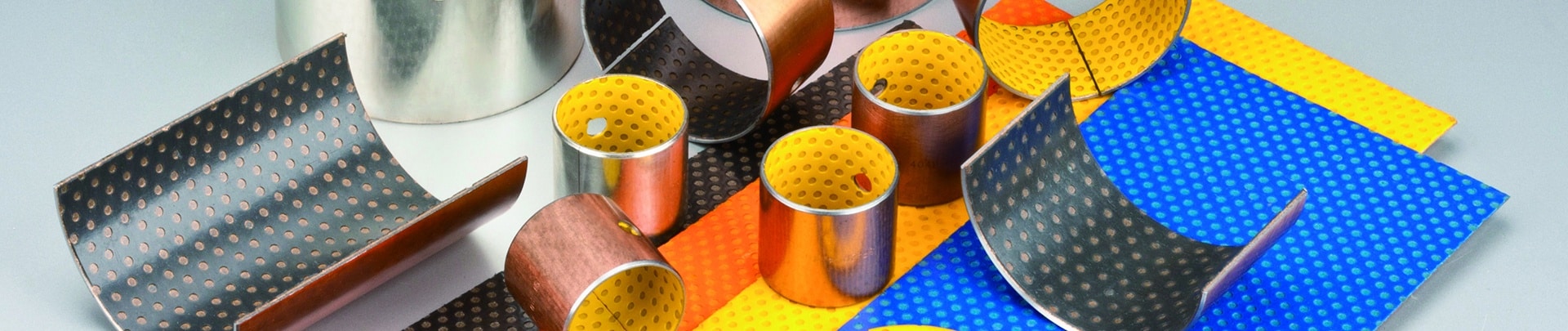

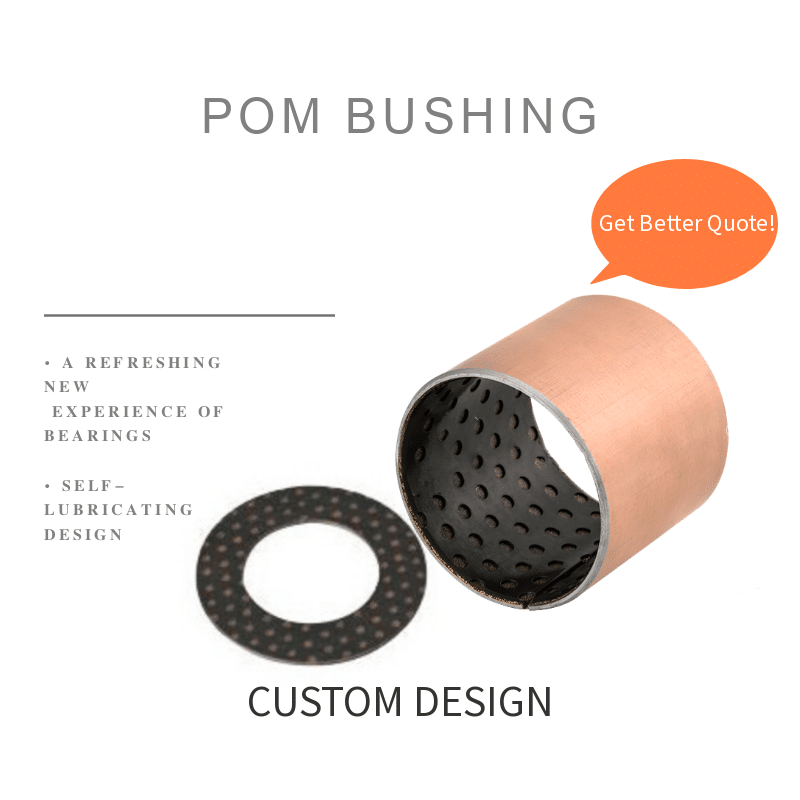

Metal Backed Bearing POM Bushing Supplier

Sintered porous bronze on a metallic substrate, embossed POM on a dynamic wear surface. boundary lubrication is required for optimum performance. High PV rating, low speed. Commonly used in mining equipment, rolling mills, ski lifts, and other applications using bronze bushings.

Engineered Composite POM bushing Solutions, Sintered porous bronze on a metal substrate with POM calendared into the dynamic wear surface. Requires boundary lubrication for optimum performance. High PV rating, low speeds. Commonly used in mining equipment, rolling mills, ski lifts, and other applications where bronze bushings are utilized.

A wide range of POM composite bushings.

Material Description: POM Composite of Steel Backing, Tin/Bronze Layer

Inch – Metric: Metric

Other Features: With Lubrication Hole

Spend less time digging through self-lubricating bearings catalogs for composite bushings POM material so you can focus on growing your plain bearing business.

Our Bushing Parts, Our Bearing Service.

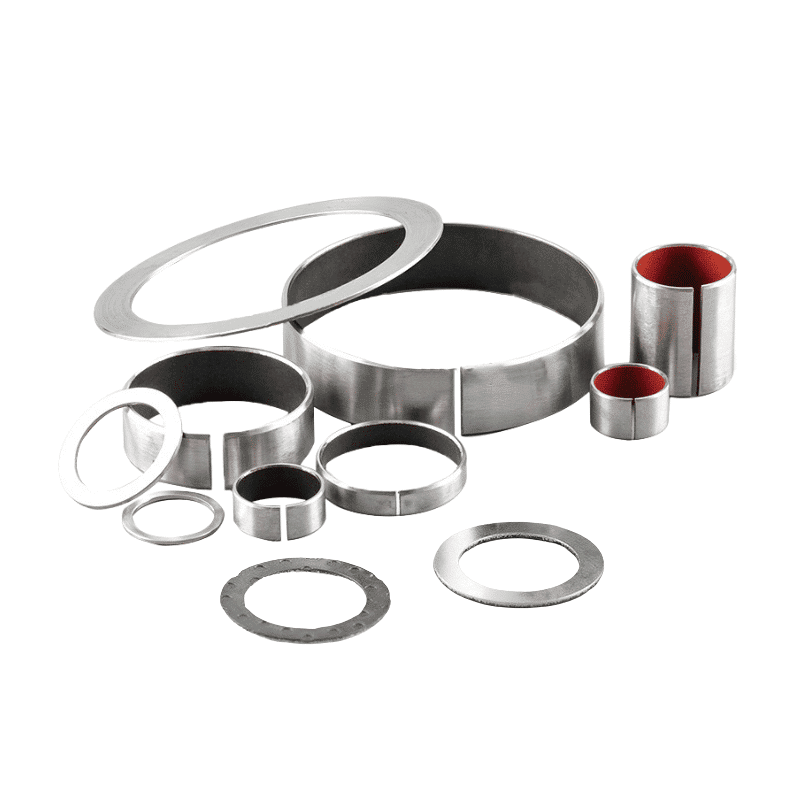

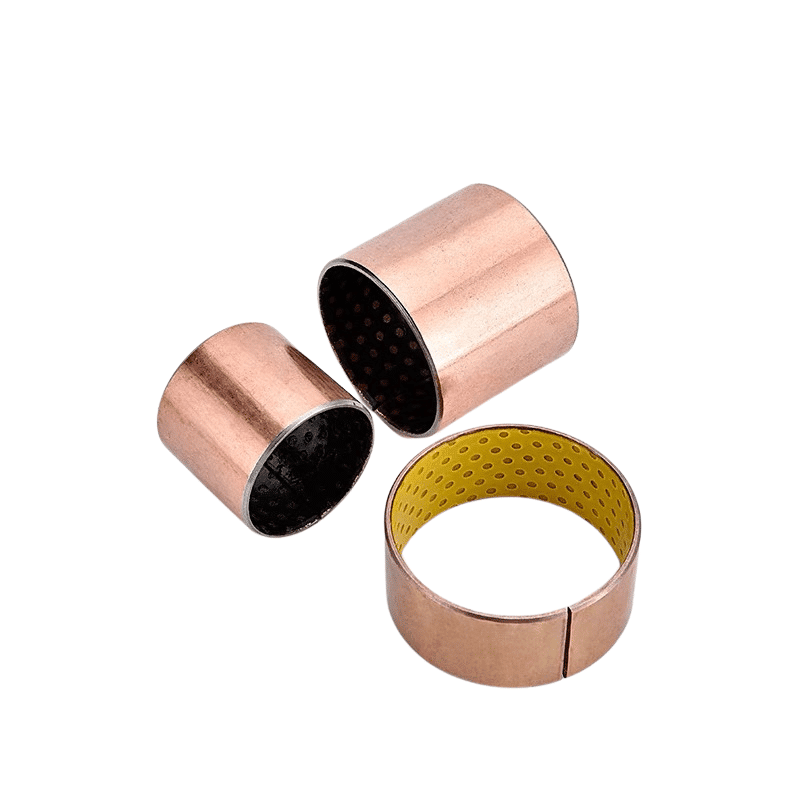

Cylindrical POM bushing – Wrapped composite sliding bushings

Bronze sliding bearings, composite bushings and engineering plastics: POM bushings

Composite Plain Bearings POM material – Metric & Inch Size

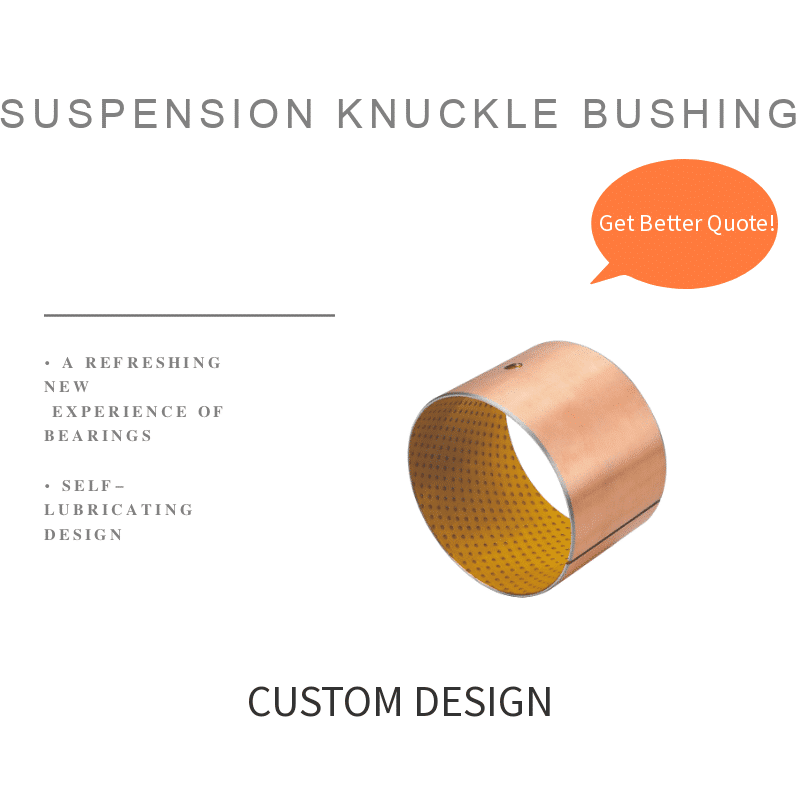

POM composite bushings are suitable for applications where a sliding material with self-lubricating properties is a prerequisite. This composite plain bearing is widely used in agricultural equipment, construction machinery, material handling equipment, home appliances, and consumer goods, etc.

- POM sliding bearings bushings for grease or oil lubricated applications

- Standard parts contain grease indents in the sliding layer; plain sliding layer available by request

- Optimum performance under relatively high loads and low speeds

- Suitable for linear, oscillating and rotating movements

- Wide range of parts available from stock

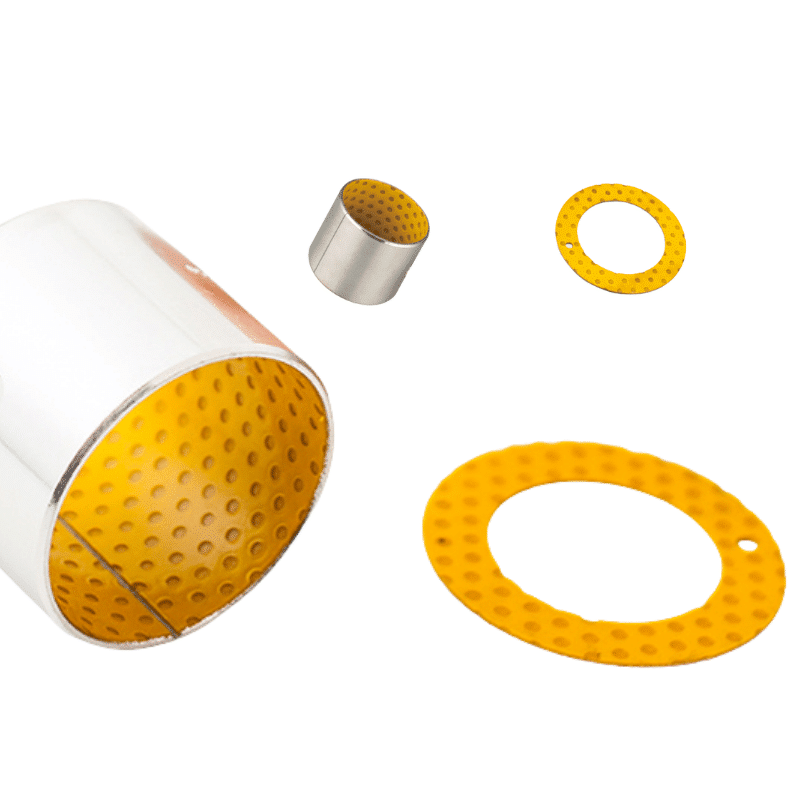

POM composite bushing material

POM composite plain bearings are suitable for applications that require minimal maintenance under difficult operating conditions. Because of the lubricant retention pockets on the sliding surface, POM composite plain bearings are particularly suitable for applications in contaminated environments where lubricant cannot be supplied continuously or frequently.

POM Marginal Bearings Structure

- POM thickness 0.30~0.50 mm, it provides high wear resistance and low friction even with the only minute volume of lubricant are supplied, this bearing surface carries a pattern of circular indents which should be filled with grease on the assembly of the bearing.

- Sintered bronze powder thickness 0.20-0.35mm, provides max. thermal conductivity away from the bearing surface also serves as a reservoir for the resin mixture.

- Low-carbon steel, provides exceptionally high load carrying capacity, excellent heat dissipation.

- Copper/Tin plating thickness 0.002mm, provides good corrosion resistance.

The POM composite bearings are suitable for rotary and oscillating movements, fewer maintenance needs due to long regreasing intervals, less wear, less sensitivity to edge loads, no water absorption and therefore no swelling, good handling behavior cushioning, good impact resistance.

POM composite bushings Lubrication

Composite plain bearings made of POM are designed to operate under extreme lubrication conditions. The sliding surface of these plain bearings contains grease reservoirs that must be filled prior to installation. Relubrication of these sleeve bearings is not required, but the presence of grease can significantly extend the life of the sleeve bearings. Grease may be periodically applied to protect the mating surface from corrosion.

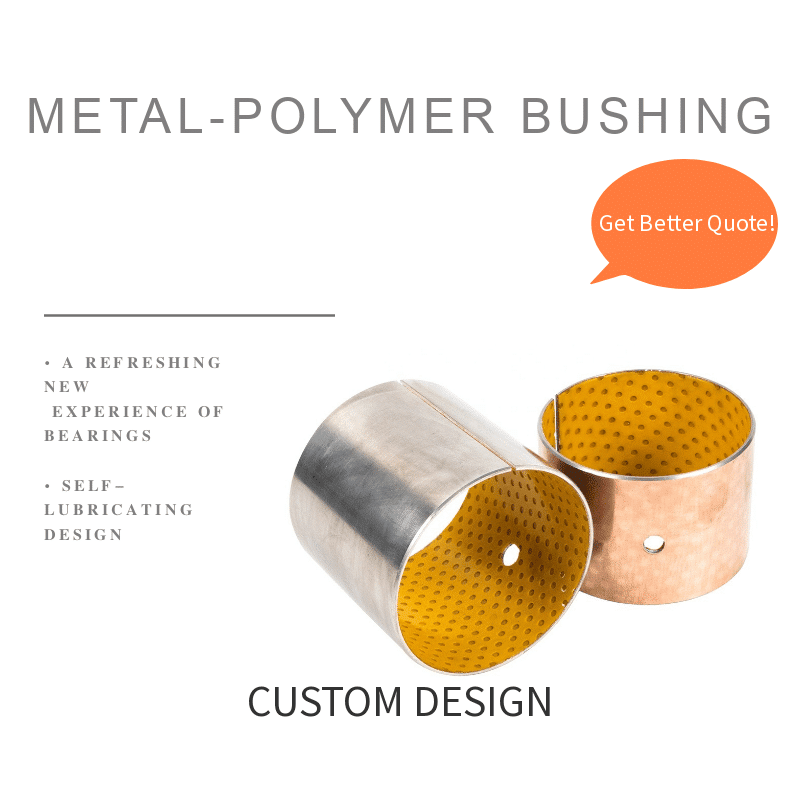

Metal-Polymer Plain Bearings Grease Lubricated

Maintenance-free & Space-saving Composite Dry Sliding Bearings Solutions

Metal-polymer composite bearing with POM material (DX bushing).

POM composite plain bearings are designed to operate under marginal lubrication conditions. The sliding surface of these bushings contains grease.

While Viiplus is recognized as the leader in sliding bearings, our product range includes composite bushings for a wide variety of contractors.

Accredited and Focused on Quality

With a variety of processes at your disposal, such as CNC machining, sheet cutting, and injection molding, we stands as your comprehensive solution for custom manufacturing.

Our High Volume Production Service Provides Dedicated Assistance For Custom Manufacturing Endeavors, Accommodating Projects Of Any Complexity And Scale.

▪ Metal Bearing Production Solutions

Your comprehensive answer for production, our team stands as the ideal choice for your manufacturing requirements.

▪ self-lubricating Bearings Solutions

With our technical specialists, the convenience of our secure quotation platform, and extensive global manufacturing capabilities, we are equipped to meet your needs.

Produce custom components as needed

We’re Your Partner From Prototyping to Production and Beyond

We provide a variety of services to assist you in creating functional prototypes and transitioning to production components. Manufacture custom parts as needed, utilizing various materials for self-lubricating bearings. Reach out to us to benefit from our expert applications engineering team’s production capabilities.

Product Quality Index

Energy Generation

Ready to get started on your custom self-lubricating bearing quote?

Breathtaking design for home living.

The variety of materials, cost-effective custom manufacturing per unit, and rapid production pace make it an excellent choice for prototyping.

Nam aliquet ante porta, gravida elit interdum, luctus porta sapien justo, at fringilla felis suscipit vestibulum.