providing factory services of superior quality with focus on efficiency.

01.

Providing Quotes for Custom Parts and Large-Scale Production Orders

02.

Satisfaction guaranteed

03.

Ensuring timely delivery

04.

Revolutionize How You Produce Custom Components

We Stand by Your Side from Initial Prototyping through to Production and Further.

Explore current topics in bearing design, bonding composite bushing, surface modification, and more.

Sintered porous bronze on a metal substrate with PTFE pressed on dynamic wear surfaces. high PV, self-lubricating, and long wear life. Commonly used for lifting and tilting applications in construction, material handling, textiles, hydraulic components, and agricultural and forestry machinery.

bronzelube.com offers a wide range of both straight and flanged sizes, PTFE composite bushings, metal-polymer composite bushing bearing, and Includes Sizes & Part Numbers.

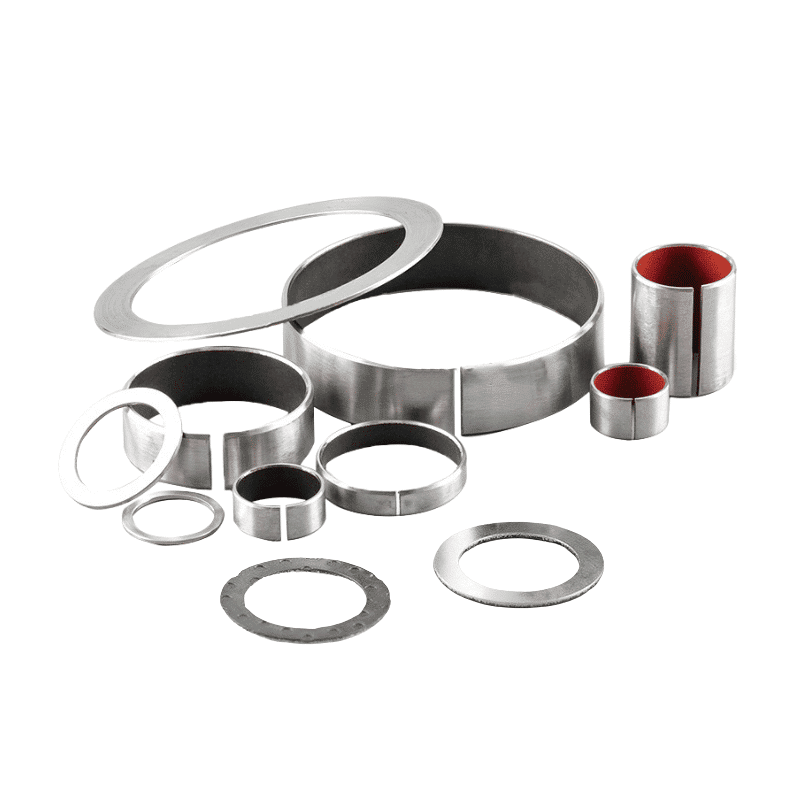

Rolled Bushing Bearings are a metal backing system with multiple lining options to optimize the solution for your unique application.

Featuring a unique polymer liner sintered into a porous bronze sandwich, Steel Backed Rolled Bushing bearings are self-lubricating and can withstand the harshest of operating environments. Steel Backed Rolled Bushing can easily handle high loads and excessive speeds and will protect your machine because the supporting intermediate layer is also self-lubricating.

Whether your job requires standard or metric sizes or steel, zinc or copper supports, Steel Backed Rolled Bushing has you covered. We’ll help you match the right material to improve the wear life of your product by evaluating your hardware for speed, load, temperature, and lubrication. And we’ll do it all at a competitive value.

Material Database

Search our database of 450+ self-lubricating bearings materials

Ask The Expert

Engineering assistance & bushing material selection support

Technical Library

Spec sheets, design worksheets, case studies & brochures.

Engineered Self-lubricating Steel backed Ptfe Bushing Solutions

Sintered porous bronze on a metal substrate with PTFE calendared into the dynamic wear surface. High PV, self-lubricating, and long wear life. Commonly used in lift and tilt applications in construction, material handling, textile, hydraulic components, agriculture, and forestry machinery.

Save money, retain quality

We keep our prices extremely competitive by always holding the component materials to manufacture your PTFE sliding bearings.

Reduce your lead times

We can complete urgent orders quickly, keep your project on track and prevent on-cost through delays.

Our years of bushing experience

We’ve been manufacturing PTFE sliding bearings for more than 10 years and have worked on many high profile projects.

A World-Leading Extrusion Partner For Advanced PTFE Sliding Bearings Solutions

A sliding bearing comprises an upper element and a lower element, which operate by sliding against one another.

The fantastic frictional properties of PTFE means it is an ideal material to be used for PTFE sliding bearings. The material has very low friction coefficients with pads and slideways made from Virgin PTFE and the use of different grades of fillers can greatly improve wear resistance and friction coefficient.

PTFE-based Self-Lubricating Metal-Polymer

STRUCTURE AND COMPOSITION

Sliding layer PTFE

Porous Bronze Sinter

Steel Backed Or Bronze Backing

The PTFE composite bushings are suitable for dry running, with low friction, less wear, good sliding characteristics, the transfer film created can protect the mating metal surface, suitable for rotary and oscillatory motion. Very high chemical resistance, low water absorption, and swelling, and very good lubricity, the bronze base provide improved corrosion resistance compared to composite PTFE bushings.

PTFE Steel bronze powder with PTFE

PTFE/Fibre mixture thickness 0.01~0.03mm, provides an excellent initial transfer film, which effectively coats the mating surfaces of the bearing assembly, forming an oxide type solid lubricant film.

Sintered bronze powder thickness 0.20-0.35mm, provides Max. thermal conductivity away from the bearing surface also serves as a reservoir for the PTFE-Fibremixture.

Low-carbon steel gives exceptionally high load carrying capacity, excellent heat dissipation.

Copper/Tin plating thickness 0.002mm, provides good corrosion resistance.

This material meets the demanding criteria for long life and trouble-free performance with or without lubrication.

Automotive: tractors, combine harvesters, sprayers, earthmovers, graders and other construction work, automotive machinery, wiper motor, tilt gears …

Office machines: photocopiers, typewriters, mail sorters, postal accounting systems, computer terminal printers and peripheral equipment, automatic printing devices, and other valves and valve pins …

Household appliances: recorders, refrigerators, air conditioners, cleaners, textile equipment, tools, etc.

Need Assistance Selecting the Proper Composite Self-Lubricating Bushings?

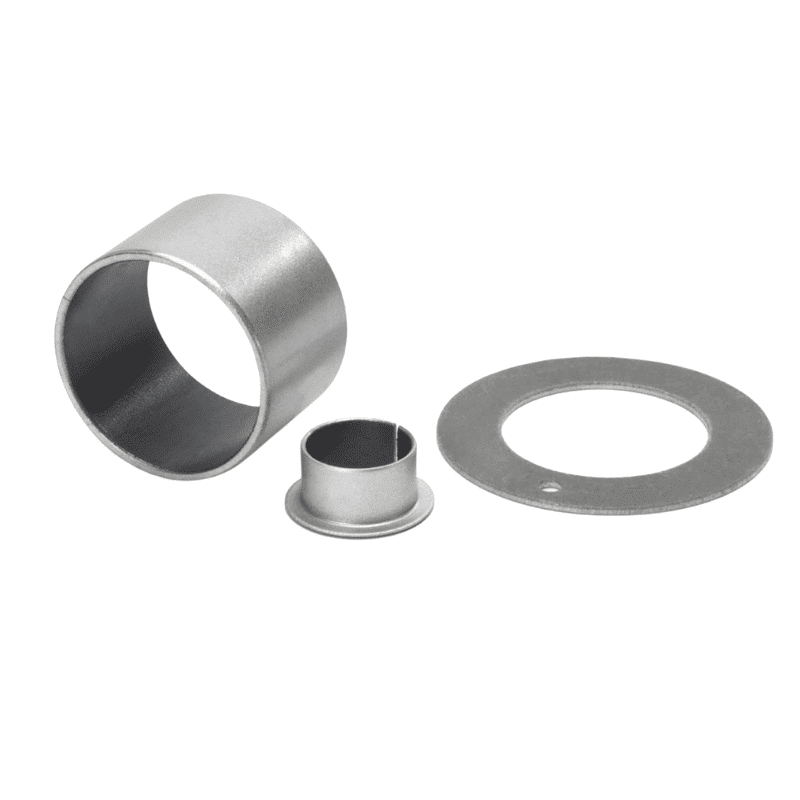

PTFE lined self-lubricating bearing, also called DU bushing, dry bushing, DU bearing, Teflon bushing, PTFE coated bearing, oil-free bearing, metal-polymer bearing with PTFE liner, and PTFE based plain bearing.

Lubrication-free bearings are used in applications where extreme part agitation and frictional force wear out on parts. These self-lubricating bearings are able to withstand high temperatures and have high load tolerances.

The PTFE-based sliding surface permits smooth, low-friction operation without lubrication.

PTFE liner metal-polymer composite bearing & PTFE based plain bearing

Standard size parts are available for a wide range of bearing products with basic dimensions (inner diameter, outer diameter, length, etc.) in accordance with international standards. Special bearings with additional functionality can be produced according to the customer’s specifications and requirements.

PTFE composite bushings in air conditioning compressors

Principle of air-conditioning heating

When heating and air conditioning, the compressor compression of high temperature and high pressure superheated steam vent discharge of the compressor, through the four-way valve directly connect the superheated steam by the indoor evaporator tube directly to the indoor machine evaporator, the evaporator of the indoor machine and now is equivalent to the condenser, overheated steam heat exchanger heat dissipation through the indoor machine, the heat generated by the tubular fan blow out from the tuyere.

Many parts of the compressor are used for PTFE composite bearing products!

PTFE composite bearings characteristics

Suitable for working parts that cannot be refueled or are difficult to be refueled, good wear resistance, low friction factor, good joint performance, low noise, no pollution, good corrosion resistance; The transfer film formed during the operation can protect the grinding shaft without the phenomenon of biting shaft. The processing requirement of dual parts is reduced, which reduces the processing cost of users. It is widely used in the general industry.

Key advantages of PTFE sliding bearing

Simplistic design and ease of fabrication and installation result in cost efficiency.

Costs of construction can be reduced by designing for expansion rather than strain.

The coefficient of friction over the bearing surface remains constant, even under worst-case scenarios.

The bearings are maintenance-free – PTFE is inherently self-lubricating, while dirt particles are absorbed into the material. Only simple protection is required against the significant ingress of dirt.

Full product information in relation to PTFE sliding bearings can be downloaded from our catalog.

Steel Backing PTE Lined Bushing Typical Applications

Agriculture

Automotive/Transportation

Railroad

Aerospace

Material Handling Equipment

Accredited and Focused on Quality

With a variety of processes at your disposal, such as CNC machining, sheet cutting, and injection molding, we stands as your comprehensive solution for custom manufacturing.

Our High Volume Production Service Provides Dedicated Assistance For Custom Manufacturing Endeavors, Accommodating Projects Of Any Complexity And Scale.

▪ Metal Bearing Production Solutions

Your comprehensive answer for production, our team stands as the ideal choice for your manufacturing requirements.

▪ self-lubricating Bearings Solutions

With our technical specialists, the convenience of our secure quotation platform, and extensive global manufacturing capabilities, we are equipped to meet your needs.

Produce custom components as needed

We’re Your Partner From Prototyping to Production and Beyond

We provide a variety of services to assist you in creating functional prototypes and transitioning to production components. Manufacture custom parts as needed, utilizing various materials for self-lubricating bearings. Reach out to us to benefit from our expert applications engineering team’s production capabilities.

Product Quality Index

Energy Generation

Ready to get started on your custom self-lubricating bearing quote?

Breathtaking design for home living.

The variety of materials, cost-effective custom manufacturing per unit, and rapid production pace make it an excellent choice for prototyping.

Nam aliquet ante porta, gravida elit interdum, luctus porta sapien justo, at fringilla felis suscipit vestibulum.