phosphor bronze bearings

phosphor bronze bearings

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand

phosphor bronze bearings

phosphor bronze bearings

Solid Bronze Bearings, Phosphor bronze bearings stand out as multifaceted components, blending strength, flexibility, and long-lasting durability. Ideal for challenging applications in diverse sectors, these bearings can enhance machinery performance and efficiency. Incorporating phosphor bronze bearings with grooves into industrial machinery can lead to a prolonged service life, decreased maintenance requirements, heightened efficiency, and superior adaptability.

Are Made From phosphor bronze Cast Bronze. Offers Standard Size Plain & Flanged Cylindrical Bushing. Solid phosphor bronze graphite self-Lubricating bushing, Brass graphite bushing, bronze bearings · Graphite Embedded Brass Bearing.

An excellent material for use in the manufacture of bearings, Phosphor Bronze is also extremely machinable. Like other phosphor bronze alloys, …

Phosphor bronze: Copper alloy containing 2% ~ 8% tin, 0.1% ~ 0.4% phosphorus and the remainder copper. Mainly used as wear-resistant parts and elastic components. Brass: Brass is an alloy of copper and zinc. If brass consists only of copper and zinc, it is called plain brass. A variety of alloys consisting of more than two elements is called special brass. Such as copper alloys consisting of lead, tin, manganese, nickel, lead, iron, and silicon. Brass has strong wear resistance.

Phosphor bronze bearing bushing Overview: finishing phosphor bronze bearing provide a simple, economical way to use bearings with high bearing, good corrosion resistance, size, and other characteristics of any process.

Safe Copper Bushing From China. Sourcing Copper Bushing from China Now. Quality China Bronze Alloy Products. Providing High-Quality Products, New Size Development Available.

Manufacturer of standard and custom phosphor bronze bearings.

Phosphor Bronze Bearings and Bushes, phosphor bronze bearings with grooves

www.bronzelube.com is your online source for bronze bushings. Shop online and have your order shipped today.

Request a Quotation for Your Slide Bearing

Phosphor bronze bushings feature high hardness, good wear resistance, low friction coefficient, good toughness, high allowable specific pressure and high limit line speed, and good processability. We offer various phosphor bronze bushings, and they are widely used in electric machinery, machine tools, tractors, ships, sugarcane pressing, paper making, cement equipment, polygraphy, light industry.

Phosphor Bronze is a copper alloy that contains significant amounts of phosphorus. The alloy also contains 0.5-11% tin. Historically, it is one of the oldest metal alloys in the world, dating back almost 4,000 years.

The material is extremely well known for its strength, durability, low coefficient of friction and fine grain. Given the presence of phosphorus, the alloy has great fluidity in the molten state and therefore offers good castability. Phosphorus acts as a deoxidizer, reduces viscosity and therefore improves fluidity, increasing stiffness and wear resistance. The introduction of tin, on the other hand, determines a significant increase in strength and resistance to corrosion.

“C5191” and “QSn6.5-0.1” are specific classifications of phosphor bronze, a type of copper alloy, that are commonly used in bushings or shaft sleeves. They have high wear resistance, excellent load-carrying capacity, and superior anti-friction characteristics.

Here are some technical specifications for C5191 and QSn6.5-0.1 phosphor bronze bushings:

- Material Composition

- C5191 Phosphor Bronze (also known as PB102 or CW451K) contains around 94-96% copper, 4.2-5.8% tin, and 0.03-0.35% phosphorous.

- QSn6.5-0.1 Phosphor Bronze (similar to C54400 or Phosphor Bronze Grade B in American standards) typically consists of about 93.5-95% copper, 4.5-5.5% tin, and 0.01-0.4% phosphorous.

- Mechanical Properties

- C5191 Tensile Strength: 370-540 MPa; Yield Strength: 105-275 MPa; Elongation: 35-55%.

- QSn6.5-0.1 Tensile Strength: 295-441 MPa; Yield Strength: 147-294 MPa; Elongation: 20-40%.

- Physical Properties

- Density: Approximately 8.9 g/cm3 for both.

- Dimensional Specifications

- Inner Diameter (ID), Outer Diameter (OD), and Length are all application-specific. They should be measured so that the bushing or sleeve fits perfectly onto the shaft and into the housing bore.

- Surface Roughness

- Same as previously mentioned: Ra 0.8-1.6 μm for the shaft, and Ra 1.6-6.3 μm for the housing bore.

- Heat Treatment

- These materials may be annealed at around 500-700°C.

- Coating

- Same as previously mentioned. Coatings like zinc, nickel, silver, gold, tin, or other types can be applied if needed.

- Temperature Range

- Phosphor bronze bushings made of these materials can typically operate efficiently in a temperature range of -40 to 400 degrees Fahrenheit.

- Lubrication

- These materials are usually self-lubricating. However, additional lubrication might be required in high-load or high-speed applications.

- Certifications

- Certifications such as ISO 9001 or AS9100 may be required, depending on the application.

Please consult with the manufacturer or an engineer for the specific requirements of your project as these specifications can change based on specific applications or manufacturing processes.

Phosphor bronze bearings & Solid bronze bushings

Switch From Bearing, Offers Standard Size Unbeatable Price Phosphor Bronze Bearing Groove Bushing. Extend The Bearing Life Of Your Equipment. Bushing lubrication, bronze self-lubricating custom Parts.

We are your specialist for plain bearings and sliding components, Development, Construction, and Manufacturing

Phosphor bronze bearing lubrication is available in metric sizes as straight or flanged bushings. This robust bushing material is suitable for a wide range of applications. These bushings are applicable for oscillating movements in both radial and axial directions or for applications where rotating speeds are low.

Phosphor bronze copper sleeve made to order from China.

We offers a wide range of professional services to support your business, Explore our extensive range of Phosphor bronze bearings to suit all applications.

Find out more about us, our team and our history.

custom made sliding bearings and special bronze groove parts

individually according to customers specifications or drawings

- individual according to drawing

- made of different plain bearing materials

Applications: Industrial – Selecting Bronze Bearing Materials

Self-lubricated phosphor bronze bearing lubrication are bearings that are manufactured with some form of pre-lubrication feature. Plugged graphite is the best lubricant for sleeve bearings. self-lubricating bushing material, phosphor bronze bearings with graphite.

Solid bronze bushings can be lubricated with oil or grease, whereas the lubricant not only improves the sliding properties but also reduces wear and prevents corrosion. Those bushings with a bore diameter d > 14 mm have an axial lubrication groove in their sliding surface and are indicated by the designation suffix G1.

All surfaces of a solid bronze bushing are machined.

customer-specific manufacturing of plain bearings and other special

Phosphor Bronze Bushing parts according to customers needs and drawings.

Phosphor Bronze Bushes at Unbeatable Price in China

OTHER BRONZE ALLOYS

| ZCuZn25Al6Fe3Mn4 | ZCuSn5Pb5Zn55-5-5 | ZCuSn6Zn6Pb36-6-3ZCuSn6Zn6Pb36-6-3 | ZCuSn10Pb110-1ZCuSn10Pb110-1 | ZCuZn25Al6Fe3Mn4 | ZCuPb10Sn1010-10 |

Phosphor Bronze type

“A type of bronze having tin and phosphorus as the principal alloying elements. It contains 2 ~ 8% tin,0.1 ~ 0.4% phosphorus and the rest is copper. Main brands: China QSN10-1, QSN6.5-0.1, QSN7-0.2, QSN8-0.3, QSN4-0.3, QSN4-3, ZQSn10, ZQSN5-5-5, ZQSN6-6-3, etc.

Switch from Bearing, Offers Standard Size Plain & Flanged Copper Groove Bushing. Extend the life of your equipment with solid bronze. Copper Alloy Bushings or bronze phosphor bronze bearing lubrication are hard and strong, almost often an alloy of bronze with tin, aluminum, or manganese, … C86300 Bronze Bushing, C93200 Bronze Bushing, C95400 Copper Alloy Bushing with groove.

Phosphor Bronzes, or tin bronzes, are alloys containing copper, tin, and phosphorous. The phosphor bronzes contain between 0.5 and 11% tin and 0.01 to 0.35 % phosphorous. The addition of tin increases the corrosion resistance and strength of the alloy. The phosphorous increases the wear resistance and stiffness of the alloy. The phosphor bronzes have superb spring qualities, high fatigue resistance, excellent formability and solderability, and high corrosion resistance. They are primarily used for electrical products, other uses include corrosion-resistant bellows, diaphragms, and spring washers. The phosphor bronze bearing with groove design. Phosphor bronzes combine good strength and fatigue resistance with good machinability, high wear resistance and corrosion resistance. They are used in applications such as sleeve bearings, thrust washers, plain bushes.

Cast bronze grooves are available in metric sizes as a straight or flanged bronze bushing. This solid bronze bushing material is suitable for a wide range of applications. The copper alloy bearing bushings are applicable for oscillating movements for applications where rotating speeds are low. … All surfaces of a solid bronze bushing are machined.

Phosphor bronze bearing lubrication Technical Parameters

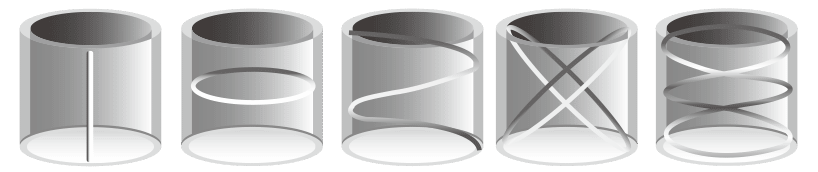

Self-Lubrication Options for Bronze Bearings Groove Design

Performance of Phosphor bronze

Phosphor bronze has higher corrosion resistance, abrasion resistance, and does not spark on impact. Used for medium speed, heavy load bearings, maximum operating temperature 250℃. It has the characteristics of automatic self-aligning, insensitive to deflection, uniform bearing capacity, radial load, and self-lubrication without maintenance. Tin phosphor bronze is a kind of alloyed copper with good electrical conductivity, low heat resistance, safety, and strong fatigue resistance. Tin phosphor bronze socket reed hardwired electrical structure, no rivets or friction contact, to ensure good contact, good elasticity, smooth insertion. The alloy has excellent machining performance and chip forming performance, which can rapidly shorten the processing time of parts. The self-lubricating copper bushing is also commonly used as phosphor bronze material.

The various bushing types, their designs, and variants are described in the following:

phosphor bronze bearings with groove

OEM parts Custom size Available. bronzelube.com can provide different grades of copper alloy according to different conditions, and in accordance with the requirements of processing different forms, it has higher accuracy than the size class copper rolling bearings.

Phosphor bronze bearing lubrication Manufacturer. Bronze phosphor bronze bearing lubrication type. Order Online Today! OEM PART. Types: Cast Bronze Standards, Bronze Material, Standard Metric Bushings, Oil-less Type Bushing, Metal Bronze Bushings.

| Available Bronze Alloy | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Types and properties of tin phosphorus bronze:

A, QSn6.5-0.1

Standard: GB/T4423-2007

Chemical composition:

Cu Cu: allowance, Tin Sn: 6.0 ~ 7.0, Lead Pb: ≤0.02, Phosphorus P: 0.10 ~ 0.25,

Al: ≤0.002, Fe: ≤0.05, Si: ≤0.002, Sb: ≤0.002, Bi: ≤0.002

Note: ≤0.1(impurity)QSN6.5-0.1 phosphorus copper

Mechanical properties:

Tensile strength σ B (MPa) : ≥470

Elongation δ5(%) : ≥13

Note: Longitudinal tensile mechanical properties of bar at room temperature

Sample size: diameter or opposite side distance 5 ~ 12

Heat treatment specification: hot working temperature 750 ~ 770℃; Annealing temperature 600 ~ 650℃.

Second, the QSn6.5-0.4

Qsn6.5-0.4 Standard: (GB/T13808-1992)

Characteristics and scope of application: Phosphor tin bronze, performance and use similar to QSN6.5-0.1, due to high phosphorus content, it has high fatigue strength, good elasticity, and wear resistance, but in hot processing has hot brittleness, can only accept cold pressure processing.

Chemical composition:

Sn: 6.0-7.0, Al: 0.002, Zn:0.3, Fe:0.02, Pb:0.02, Ni:0.2, P:0.26-0.40, Cu: allowance, impurity: 0.1

Mechanical properties:

Tensile strength: (σb/MPa) ≥355

Elongation (δ10/%)≥50 elongation (δ 5/%)≥55

Third, QSn7-0.2

Qsn7-0.2 Standard: GB/T2059-2000

Characteristics and scope of application: QSN7-0.2 tin bronze has high strength, good elasticity and wear resistance, easy welding and brazing, good corrosion resistance in air, fresh water and sea water, good machinability, suitable for hot pressing.

Qsn7-0.2 phosphor bronze is used to make parts bearing friction under medium load and medium sliding speed, such as anti-wear gaskets, bearings, bushings, turbines, etc., and can also be used as springs, reeds, etc.

Chemical composition:

Cu Cu: allowance, Tin Sn: 6.0 ~ 8.0, Lead Pb: ≤0.02, Phosphorus P: 0.10 ~ 0.25, Al: ≤0.01,

Fe: ≤0.05, Si: ≤0.02, Sb: ≤0.002, Bi: ≤0.002, Note: ≤0.15(impurities)

Mechanical properties:

Tensile strength σ B (MPa) : ≥665

Elongation δ10(%) : ≥2

Note: Tensile mechanical properties of strip at room temperature specimen size: thickness ≥0.15

A bronze containing 3 to 14 percent tin, often supplemented by phosphorus, zinc, and lead.

Is the human application of the earliest alloy, has been about 4000 years of use history. It is corrosion-resistant, wear-resistant, has good mechanical properties and process properties, and can weld and braze well, impact does not produce sparks. It is divided into processed tin bronze and cast tin bronze. The content of tin bronze used for pressure machining is less than 6% ~ 7% and that of cast tin bronze is 10% ~ 14%.

Commonly used brands are QSN4-3, QSN4.4-2.5, QSN7-O.2, ZQSn10, ZQSN5-2-5, ZQSN6-6-3, etc. Tin bronze is a non-ferrous metal alloy with the smallest shrinkage, which can be used to produce castings with complex shapes, clear Outlines and low air tightness requirements.

Tin bronze is very corrosion resistant in air, seawater, fresh water and steam, and is widely used in steam boilers and Marine parts. Phosphor tin bronze has good mechanical properties and can be used as wear-resisting and elastic parts of high precision working machine.

The difference between self-lubricating bearing and oil-bearing:

oil-bearing takes metal powder as the main raw material and sintered body made by powder metallurgy. It is porous in nature and has the technical advantages of being able to freely adjust the number, size, shape, and distribution of pores in the manufacturing process. Make use of the porosity of the sintered body, so that it contains 10%~40%(volume fraction) lubricating oil, and it is used under the condition of self-feeding oil. When running, the bearing temperature rises, because the expansion coefficient of oil is larger than that of metal, it automatically enters the sliding surface to lubricate the bearing. Oil-bearing oil can be used for a long time, often used for refueling inconvenient occasions.

Metal base inlaid solid self-lubricating bearing is a novel lubricating bearing that has both the characteristics of metal bearing and self-lubricating bearing. The metal base bears the load, and the solid lubricating material with special formula plays the lubrication role. It has the characteristics of high bearing capacity, impact resistance, high-temperature resistance, strong self-lubrication ability, especially suitable for heavy load, low speed, reciprocating or swing, and other difficult lubrication and oil film formation occasions, also not afraid of water and other acid erosion and scouring. Inlaid bearings not only save oil and energy, but also their working life is longer than ordinary plain bearings. At present, the products have been widely used in a metallurgical continuous casting machine, rolling equipment, mining machinery, ships, steam turbines, water turbines, injection molding machines,s and equipment production lines.

1. Oil-bearing is a combination of metal powder with 10~40% structural clearance; The matrix of inlaid self-lubricating bearing is made by centrifugal casting. The substrate density is relatively high, the binding strength is higher than that of oil-bearing bearings, and the service life is longer than that of oil-bearing bearings.

2. The lubricating material of oil-bearing is lubricating oil, and the oil film has enough thickness to eliminate the direct contact between the two friction surfaces. At this point, there is only friction between liquid molecules, so the friction coefficient is very small (F = 0.001-0.008), which significantly reduces friction and wear. The lubricating material of embedded self-lubricating bearing is solid lubricating material. Even in the condition of no oil, it can still achieve good lubrication effect and ensure the uninterrupted and sustainable lubrication. Its effective lubrication life is consistent with the life of the matrix.

3. The lubricating oil in the oil-bearing is volatile and easy to lose, and the lubricating oil film loses faster under high temperature and high pressure, so it cannot achieve the due lubrication effect; And the solid lubricant through friction, solid lubricant in the hole or groove to the friction surface transfer or reverse transfer, in the friction surface to form good lubrication, solid adhesion and uniform coverage of the solid transfer film, greatly reduce the friction and wear. As the friction goes on, the solid lubricant embedded in the friction surface is constantly provided to ensure the good lubrication of the friction pair during long-term operation.

Our company produces oil-bearing, self-lubricating bearing graphite copper bushing, advanced casting technology, can effectively prolong the life of mechanical parts.

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally