Spherical Plain Bearing

Spherical Plain Bearing

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand

Spherical Plain Bearing

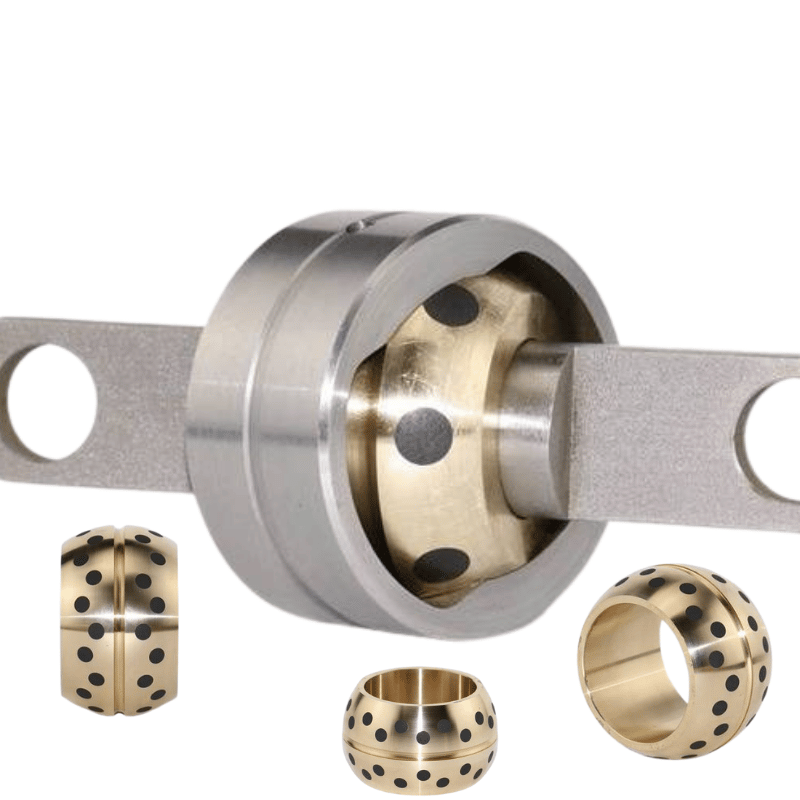

Spherical plain bearing graphite plain bearings are a reliable, cost-efficient solution for applications with multi-directional, self-aligning movements.

Shop a large range of Spherical plain bearings rod end, thrust spherical plain bearing, rod ends bearings – maintenance-free self-lubricating at bronzelube.com. Support all your size range: Available from 12.7 mm – 600 mm (0.500 in. to 23.622 in.) bore … with excellent quality, to win customers of all ages.

ball material is made with high-strength copper alloy, and the inserted solid lubricant materials are made with graphite and PTFE.

Outer ring of carbon chromium steel, fractured, hardened and phosphated, surface treated with MoS2.

Key Characteristics:

1. Based on GE type of spherical bearing.

2. Extremely high load capacity, good anti-wear and low friction.

3. Particularly appropriate for low speed and high load.

4. Suitable for oscillation or intermittent motion where oil film is hard to be formed.

5. Good chemical resistant and anti-corrosion characteristics.

Applications

- Cylinders for mining trucks

- Equalizer track bars, lift and tilt cylinders, push blades, trunnion balls, and ripper blades for bulldozers

- Articulated joint upper and lower steering cylinders and boom and bucket cylinders for wheel loaders

- Stick and bucket cylinders for hydraulic excavators

- Additional applications for space shuttles, heavy movable structures, and miscellaneous vehicles

Spherical plain bearing – maintenance-free, thrust spherical plain bearing, rod ends bearings.

Self-lubricating Spherical Plain Bearings are unique in design, offering long-lasting performance and maintenance-free operations. They are a perfect solution for applications that require movements at pivot points, making them especially beneficial for various industries, including aerospace, automotive, and industrial machinery.

We offer both custom-made and standard self-lubricating spherical plain bearings. These bearings do not require any additional lubrication (i.e., grease), reducing the cost and time spent on maintenance. This key feature also significantly increases the bearing’s lifespan, offering a more efficient and sustainable solution.

Our spherical plain bearings are available in two designs:

- Radial Spherical Plain Bearings: These bearings are designed to accommodate radial loads and can handle a significant amount of force from different directions.

- Axial Spherical Plain Bearings: These are specifically designed to accommodate axial loads and are often used in applications with heavy thrust loads.

Our self-lubricating materials consist of an inner ring made of hard steel coupled with an outer ring that is self-lubricating. This combination ensures optimal performance, longevity, and reliability, as well as reducing friction and wear.

In summary, our self-lubricating spherical plain bearings offer multiple benefits, including decreased maintenance, increased lifespan, and improved operational efficiency. Whether you require a radial or axial design, we can provide a solution tailored to your specific needs.

The GE 200 ES GE200ES spherical bearing is a self-lubricating bearing with plugged graphite, designed to provide smooth and efficient operation in various applications. As a radial spherical plain bearing, it is specifically engineered to accommodate radial and combined radial and axial loads, as well as misalignment. This type of bearing is ideal for heavy static, alternating, or impact loads, making it suitable for a wide range of industries and applications.

Key features of the GE 200 ES GE200ES spherical bearing include:

- Steel/Steel Sliding Contact Surface Combination: This design ensures durability and reliable performance, even under heavy loads and challenging conditions.

- Maintenance Requirements: Although these bearings are self-lubricating, they still require periodic maintenance and can be relubricated through lubrication holes and an annular groove in both rings. This helps to prolong the bearing’s service life and maintain optimal performance.

- Load Capacity: The GE 200 ES GE200ES spherical bearing is designed to handle radial and combined radial and axial loads, making it suitable for use in applications that require excellent load-carrying capacity.

- Misalignment Accommodation: Radial spherical plain bearings like the GE 200 ES GE200ES are specifically designed to accommodate misalignment, ensuring smooth operation even when the components they are connected to are not perfectly aligned.

- Versatility: Due to their load capacity, misalignment accommodation, and suitability for heavy static, alternating, or impact loads, these bearings are versatile and can be used in various applications across multiple industries, such as construction, agriculture, heavy machinery, and automotive.

The GE 200 ES GE200ES spherical bearing is a high-quality, self-lubricating bearing that is designed to accommodate radial and combined radial and axial loads, as well as misalignment. Its steel/steel sliding contact surface combination ensures durability, while its maintenance requirements help extend the bearing’s service life. This bearing is ideal for use in heavy-duty applications that require excellent load-carrying capacity and misalignment accommodation.

Oilless Spherical Plain Bearing, Professional production of sliding type self-lubricating bearing factory. Company products are completely covered with self-lubricating properties of various materials, various types of sleeve bearings, sliding plates, gaskets, and shaft series

spherical plain bearing graphite plain bearings are a reliable, cost-efficient solution for applications with multi-directional, self-aligning movements.

supplies a wide assortment of radial spherical plain bearings with various sliding contact surface combinations. Designs, series and variants.

Maintenance-free, self-lubricating, corrosion resistant, good vibration damping, etc.

Self-aligning, maintenance-free spherical bearings made of high performance are available as base bearings, rod-end bearings and spherical bearings. Self-aligning bearings are easy to mount and can be used in all angles of deflection and can replace special bases in many applications. Users of these bearings can find all the advantages of high performance self-lubricating graphite spherical plain bearings: spherical plain bearings. They are cost-effective in terms of mounting space, purchase and maintenance, and significantly reduce maintenance and mounting costs.

Radial spherical plain bearing corrosion and chemical resistant solution

Radial spherical plain bearings are designed to accommodate radial and combined radial and axial loads, and also misalignment. This specific design includes a steel/steel sliding contact surface combination and a double-lip contact seal on both sides. The bearings require maintenance and can be relubricated via lubrication holes and an annular groove in both rings.

- Designed for radial and combined radial and axial loads

- Long service life

- Minimal maintenance

- Suitable for heavy static, alternating or impact loads

Radial spherical plain bearings, spherical bearing lubrication

Good vibration damping

Maintenance-free, dry running

High strength, impact load resistant

Corrosion resistance as well as chemical resistance

Compensated alignment errors and edge loading

The standard ball is made of high wear-resistant graphite copper sleeve material, which has high load capacity and very low friction coefficient in dry running, especially suitable for high load and low speed movement. We can also take other standard wear-resistant materials to make the spheres, so as to improve the special performance of the joint bearings.

Supply a wide assortment of radial spherical plain bearings with various sliding contact surface combinations. Designs, series and variants. download the below catalog!

Steel Outer With Bronze Alloy Inner Series SPB Series for Cold rolling mill, spherical bearing lubrication

oscillating bearing; spherical plain bearing for four-high cold strip mill, plain bearings are a reliable, cost-efficient solution for applications with multi-directional, self-aligning movements.

Cold rolling machine is a new type of steel bar cold rolling processing equipment. The machine can process hot rolled coils and hot rolled discs with diameters between 6.5 mm and 12 mm into cold rolled ribbed steel bars with finished specifications from 5 mm to 12 mm in diameter. The cold rolled ribbed steel bars rolled with the cold rolling mill are the newer product of cold drawn low carbon steel wire in prestressed concrete members, and in cast-in-place concrete structures, they can replace Grade I steel bars to save steel, which is one of the better cold processed steel of its kind. If the rolling process in the cold rolling mill does not require speed regulation, AC motor can be used; if the rolling process in the cold rolling mill requires speed regulation, a DC motor can be used.

Cold rolling mill in the production process to ensure the safe use of self-lubricating bearings and mechanical parts of cold rolling mill equipment and product qualification.

Spherical Plain Bearings, Standard Parts

JDBS Oilless spherical plain bearing

Spherical plain bearings are manufactured in a wide variety of materials and are designed to offer bearing solutions in almost any operating environment. Graphite Bushing Plain Bearings offers a complete line of spherical bearings available in inch and metric. These High-Quality Spherical Plain Bearings are suitable for heavy-duty, off-highway vehicles, agricultural equipment, construction and mining and logging equipment, packaging and textile equipment, and robotics. The plain bearings come in standard industrial bore sizes from 0.5″ to 12″ inches, as well as metric sizes from as small as 4 to 300 mm. Custom sizes can also be ordered.

Spherical plain bearings Oilless Lubricated Bushing. A Steel-on-Copper alloy Spherical Plain Bearing is one type of maintenance-free graphite bushing (others include Steel-on-PTFE materials and steel on bronze). The load ratings for Steel-on-Copper alloy are somewhere between Steel-on-Bronze and Steel-on-PTFE plastic.

Material 500#SP + Graphite outside material SUJ2+MoS2 surface

Product Introduction:

A self-lubricating plain bearing is a kind of space motion plain bearing with self-lubricating performance, which can rotate or swing in any direction. The self-lubricating plain bearing consists of the inner ring and outer ring.

Product features:

The product has a high bearing capacity, small friction coefficient, automatic self-aligning, can bear radial and axial loads at the same time, no maintenance, long service life, wide application range, and so on.

Product Application:

The product is widely used in hydraulic machinery arc gates, plane gates, miter gates, a hydraulic hoist and tubular turbine water guide mechanism, and other equipment.

| SIZE | JDB-1 | JDB-2 | JDB-22 | JDB-23 | JDB-3 | DB-4 | JDB-5 |

|---|---|---|---|---|---|---|---|

| GB1776-87 | ZCuZn25 Al6Fe3Mn3 | ZCuSn6Zn6Pb3 | ZCuAl10Fe3 | ZCuSu10P1 | Steel+ ZCuSn6Zn6Pb3 | HT250 | GCr15 |

| ISO1338 | GCuZn25 Al6Fe3Mn3 | GCuSn6Zn6Pb3 | GCuAl10Fe3 | – | Steel+ CuSn6Zn6Pb3 Fe3Ni5 | – | B1 |

| DIN | G-CuZn25 Al5 | GB-CuSn5Zn5Pb5 | GB-CuAl10Ni | GB-CuSn10 | Steel+ CuSn6Zn6Pb3Ni | – | 100Cr6 |

| JIS | HBsC4 | BC6 | AIBC3 | BC3 | BC6 | FC250 | SUJ2 |

| ASTM/UNS | C86300 | C83600 | C95500 | C90500 | C83600 | Class40 | 52100 |

| (BS) | HTB2 | LG2 | AB1 | PB4 | LG2 | – | – |

Spherical bearing lubrication Characteristics and application of joint bearing, oilless bushing supplier

Radial Spherical Plain Bearings with graphite, Size range: Available from 12.7 mm – 600 mm (0.500 in. to 23.622 in.) bore.

A type of Special spherical plain bearings with maintenance-free bronze ball bearing.

Thrust spherical plain bearing, rod ends bearings, Hydraulic engineering safety door self-lubricating joint bearing JDBS radial bearing wear-resistant oil-free lubrication maintenance free.

Stainless steel, C45 Steel or GCr15 outer ring.

Bronze bearing interring(CuZn25Al5, CuAl10Ni, CuSn12).

The products are self-lubricating bearings, sliding bearings, composite bearings, bushings, bushings, oil-free bearings, solid inlay bearings, dry bearings, shaft tiles, flat bearings, guide bushings, bimetallic bearings, self-lubricating bearings, oil-free bearings, flanged bearings, reciprocating bearings, stainless steel self-lubricating bearings, gear oil pump bearings, thrust spacers, ball guide bushings (roller cage), mold guide pillar, mold frame, mold guide bushings The standard parts for automotive moulds such as the bevel wedge. These products are mainly used in the automotive industry (steering knuckle bushings, rocker arm bushings, booster pump bushings, shock absorbers), valves, pumps and valves, lifts, hydraulic trucks, power tools, textile machinery, rubber machinery, printing machinery, food machinery, packaging machinery, lifting machinery, mining machinery, fitness equipment, water conservancy machinery, machine tools, hydraulic turbines, steam turbines, injection molding machines, plastic molding machines, metallurgical equipment, molds, Hydraulic machinery, cylinders, pneumatic components, cylinders, petroleum machinery, plastic machinery, pharmaceutical machinery, automation equipment, engineering machinery, construction machinery, forging equipment, chemical machinery, steel rolling equipment, etc.

Tin bronze contains 3% to 14% tin, in addition to phosphorus, zinc, lead and other elements often added. It is the earliest alloy used by mankind, and has been used for about 4000 years. It is corrosion-resistant, wear-resistant has good mechanical properties and process properties, can be well welded and brazed, and does not produce sparks when impacted. It is divided into processed tin bronze and cast tin bronze. Tin bronze used for pressure processing contains less than 6% to 7% tin, and the tin content of cast tin bronze is 10% to 14%. Commonly used grades include QSn4-3, QSn4.4-2.5, QSn7-O.2, ZQSn10, ZQSn5-2-5, ZQSN6-6-3, etc. Tin bronze is a non-ferrous alloy with the smallest casting shrinkage, and can be used to produce castings with complex shapes, clear contours and low airtightness requirements. Tin bronze is very resistant to corrosion in the atmosphere, seawater, fresh water, and steam.

Bronze bushings, also known as copper bushings, are divided into various types, including machine bronze rollers and bronze bearings. It is used in various light, large and heavy machinery, and is an important component part of the machinery. The product has the traditional function of tin bronze bearing, with electrolytic copper as the raw material with a variety of trace metal elements, sintered at high temperature and processed by pneumatic centrifugal casting. High hardness, excellent wear resistance, not easy to produce bite phenomenon, good casting performance and cutting performance, good corrosion resistance in the atmosphere and fresh water. In the lack of lubricant and with water lubricant conditions, good sliding and self-lubricating properties, easy to cut, poor casting performance, good corrosion resistance to dilute sulfuric acid. General-purpose structural parts, ships, instruments and other simple castings, such as sleeves, bushings, shaft tiles, sliding blocks, etc.

Bronze with tin as the main alloy element. The tin content is generally between 3 and 14%, mainly used for making elastic components and wear-resistant parts. The tin content of deformed tin bronze does not exceed 8%, and sometimes phosphorus, lead, zinc, and other elements are added. Phosphorus is a good deoxidizer and also improves fluidity and wear resistance. The addition of lead to tin bronze improves machinability and wear resistance, and the addition of zinc improves casting properties. This alloy has high mechanical properties, wear reduction and corrosion resistance, easy cutting and processing, good brazing and welding performance, small shrinkage coefficient, non-magnetic. Available wire flame spraying and arc spraying preparation of bronze bushings, bushings, anti-magnetic components and other coatings. Size specifications Ф1.6mm, Ф2.3mm. with high strength, corrosion resistance and excellent casting properties, has long been widely used in various industrial sectors

In the absence of lubricants and with water lubricant conditions, sliding and self-lubricating properties, easy cutting, casting performance is poor, good corrosion resistance to dilute sulfuric acid.

High surface pressure, and side pressure bearings, can be used to manufacture copper cooling tubes for cold rolling mills, impact load resistance

Maintenance-free features quite long service life. Conforms to ISO Standard E type bearings. High precision. The inner surface of the inner ring is subject to sliding. Suitable for higher load than other self-lubricating spherical bearings. Customized design can be made on your requirement.

A plain bearing is a kind of sliding bearing with a special structure, which is mainly composed of an inner ring with an outer sphere and an outer ring with an inner sphere. It can swing and rotate in any direction. Generally, it can bear a large load and has the characteristics of high load-bearing, impact resistance, wear resistance, self-aligning and good lubrication.Because the outer sphere of the inner ring is usually inlaid with composite materials, the joint bearing can produce self-lubrication in operation. Generally used for low-speed swing motion and low-speed rotation, but also in a certain Angle range of tilt motion, when the supporting shaft and shaft shell hole concentricity is large, it can still work normally. Widely used in low-speed swing motion, tilt motion, and rotary motion, such as nuclear power, aerospace, engineering hydraulic cylinder, forging machine tools, construction machinery, automation equipment, automotive shock absorber, hydraulic machinery, and many other industries and fields, is the core components to determine the host operation performance.

Spherical Plain Bearing, graphite oilless bushing/bearing Size

Sphere Oscillating Bearing inner ring plugged graphite

| Standard No. | d(H7) | D1(h6) | B | C | D | b | Alignment Angle (°) | Allowable Radial Load (kN) | Allowable Thrust Load (kN) |

|---|---|---|---|---|---|---|---|---|---|

| JQB-015 | 15 | 26 | 12 | 9 | 22 | 4 | 8 | 6.5 | 0.5 |

| JQB-020 | 20 | 32 | 16 | 14 | 28 | 4 | 4 | 12.6 | 1.4 |

| JQB-025 | 25 | 42 | 21 | 18 | 36 | 4 | 5 | 21.8 | 2.5 |

| JQB-030 | 30 | 50 | 27 | 23 | 44 | 4 | 6 | 32 | 3.5 |

| JQB-035 | 35 | 55 | 30 | 26 | 49 | 4 | 5 | 43.7 | 4.8 |

| JQB-040 | 40 | 62 | 33 | 28 | 55 | 4 | 6 | 54.7 | 5.7 |

| JQB-045 | 45 | 72 | 36 | 31 | 62 | 4 | 5 | 69.7 | 7.2 |

| JQB-050 | 50 | 80 | 42 | 36 | 70 | 4 | 5 | 92.4 | 10 |

| JQB-060 | 60 | 100 | 53 | 45 | 90 | 4 | 6 | 143 | 16 |

| JQB-070 | 70 | 110 | 58 | 50 | 99 | 4 | 5 | 181 | 20 |

| JQB-080 | 80 | 130 | 70 | 60 | 115 | 4 | 6 | 254 | 30 |

| JQB-090 | 90 | 140 | 76 | 65 | 125 | 4 | 6 | 313 | 36 |

| JQB-100 | 100 | 160 | 88 | 75 | 145 | 6 | 6 | 544 | 64 |

| JQB-110 | 110 | 170 | 93 | 80 | 155 | 6 | 5 | 642 | 73 |

| JQB-120 | 120 | 190 | 105 | 90 | 170 | 6 | 6 | 797 | 94 |

| JQB-130 | 130 | 200 | 110 | 95 | 180 | 6 | 5 | 880 | 105 |

| JQB-140 | 140 | 210 | 90 | 70 | 180 | 6 | 7 | 668 | 56 |

| JQB-150 | 150 | 220 | 120 | 105 | 200 | 6 | 5 | 1135 | 129 |

| JQB-160 | 160 | 230 | 105 | 80 | 200 | 6 | 8 | 891 | 73 |

| JQB-180 | 180 | 260 | 105 | 80 | 225 | 6 | 6 | 1002 | 74 |

| JQB-200 | 200 | 290 | 130 | 100 | 250 | 6 | 7 | 1434 | 117 |

| JQB-220 | 220 | 320 | 135 | 100 | 275 | 6 | 8 | 1577 | 118 |

| JQB-240 | 240 | 340 | 140 | 100 | 300 | 9 | 8 | 1720 | 118 |

| JQB-260 | 260 | 370 | 150 | 110 | 325 | 9 | 7 | 2075 | 143 |

| JQB-280 | 280 | 400 | 155 | 120 | 350 | 9 | 6 | 2455 | 172 |

| JQB-300 | 300 | 430 | 165 | 120 | 375 | 9 | 7 | 2630 | 172 |

Graphite Plain bearing on processing solutions. Custom Bearing Services. Cost-Efficient Parts. Wide Range Of Products. Services: Engineering.

Spherical Plain Bearing, Shop for CopperBushings at BRONZELUBE.COM

Engineered for a Longer More Reliable Service Life, Metric Spherical Plain Bearing.

High Strength Spherical Plain Bearing, Customized Processing Self Lubricating Bearing – Resistant

Spherical Plain Bearing, Graphite Copper Bushing Self Lubricating Materials High Strength.

Spherical plain bearings and rod ends, Spherical Plain Bearings

According to its different types and structure, it can bear radial load, axial load or radial, and axial combined load. It can be generally divided into centripetal joint bearings, angular contact joint bearings, thrust joint bearings, rod end joint bearings, and other types.

Spherical Plain Bearing Supplier

Focus, the pursuit of “spirit”, and always continuous innovation, customer and social needs as the guidance, constantly moving forward, with the advantages of on the self-lubricating material technology, can provide products to satisfy different working conditions of self-lubricating bearing joints, including engineering plastics modified joint bearing, metal base self-lubricating bearing joints, and used in high temperature, high load conditions of special products.

Application of Spherical Plain Bearing :

Can be widely used in hydraulic cylinder, hydraulic machinery of all kinds of gate and arc gate, plane gate, miter gate, hydraulic hoist and tubular turbine, etc., of the high-rise building wind shock joints, steam generator support for nuclear power, voltage regulator support rod, wind-power blades is analyzed.studying system, cable hanger, long-span Bridges and cable bridge deck and domain in areas such as the connection.

With the vision of creating value through high-performance self-lubricating bearings and their technical solutions, we will continue to increase investment in scientific research and technological innovation, and contribute to the industry and society.

The products are self-lubricating bearings, sliding bearings, composite bearings, bushings, bushings, oil-free bearings, solid inlay bearings, dry bearings, shaft tiles, flat bearings, guide bushings, bimetallic bearings, self-lubricating bearings, oil-free bearings, flanged bearings, reciprocating bearings, stainless steel self-lubricating bearings, gear oil pump bearings, thrust spacers, ball guide bushings (roller cage), mold guide pillar, mold frame, mold guide bushings The standard parts for automotive moulds such as the bevel wedge. These products are mainly used in the automotive industry (steering knuckle bushings, rocker arm bushings, booster pump bushings, shock absorbers), valves, pumps and valves, lifts, hydraulic trucks, power tools, textile machinery, rubber machinery, printing machinery, food machinery, packaging machinery, lifting machinery, mining machinery, fitness equipment, water conservancy machinery, machine tools, hydraulic turbines, steam turbines, injection molding machines, plastic molding machines, metallurgical equipment, molds, hydraulic machinery, cylinder, pneumatic components, oil cylinder, petroleum machinery, plastic machinery, pharmaceutical machinery, automation equipment, engineering machinery, construction machinery, forging equipment, chemical machinery, steel rolling equipment, etc.

Joint bearing is a spherical sliding bearing, its sliding contact surface is an inner spherical surface and an outer spherical surface, the movement can be rotated at any angle swing, it uses the surface phosphating, blowing mouth, pad, spraying and other special technology processing methods to produce. The joint bearing has a large load capacity, impact resistance, corrosion resistance, wear resistance, self-aligning, good lubrication and other characteristics.

Joint bearings are widely used in engineering hydraulic cylinders, forging machine tools, engineering machinery, automation equipment, automotive shock absorbers, water conservancy machinery and other industries. Joint bearings are spherical plain bearings, the basic type is composed of inner and outer rings with the spherical sliding spherical contact surface. According to its structure and type, it can bear radial load, axial load, or radial, axial simultaneous action of the combined load.

Metal spherical plain bearings and plastic spherical plain bearings, spherical bearing lubrication

What details should I pay attention to when using metal spherical plain bearings and plastic spherical plain bearings?

Metal joint bearings can move under high load and its high speed; the tensile strength of metal joint bearing threads is higher than plastic joint bearings, usually the force on plastic joint bearing threads is half that of metal; when metal joint bearings are installed, the interference fit between the pin and the hole is interference fit; when plastic joint bearings are installed, the pin and the hole are clearance fit, and the pin needs additional clamps to prevent the pin from crosstalk.

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally