Get composite bearings solutions from bronzelube.com

A professional composite bushing expert will work with you

Innovation & Knowledge

Composite Bushings – Factory Direct Price

Beautifully crafted leather products.

Wrapped sliding bearing, POM composite bushing, steel/POM sliding layer, DIN 1494/ISO 3547, Low-maintenance, Pom Bearings – DU, DX alternative bushings, SKF composite alternative bushings, equivalent bushing – Call Our Team of Experts.

Composite bearings Design, Precision Bushings

Beautifully crafted leather products.

The performance of composite bearings, which also includes bushings, thrust washers, and strips, depends largely on the interaction of load, lubrication, surface roughness, sliding speed, and operating temperature in a specific application.

This makes it impossible to include all the information to cover every conceivable application. Therefore, we refer to the bushing application engineering service when needed.

Customized Bushing & Composite Bearing

Cylindrical bush Low-maintenance with lubrication pockets. for low-maintenance, lubricated applications. Metric, Bushing, bushing Factory and Manufacturers China – Low Price. Customized Bushing Suppliers, Manufacturers, Factory …Self-Lubricating Bearing Sleeve Bronze Bushing …

Composite PLAIN BEARING bushing – Long-term Wear Resistance

Models and tables of dimensions For composite Bearing

Standard sliding materials with a high performance. They are designed for low-maintenance grease. This is the type of coating to be applied on this smooth ring. Self-lubricating PTFE (Polytetrafluoroethylene) coating that will require no maintenance. PTFE (Polytetrafluoroethylene) self-lubricating honeycomb coating with a grease hole that will allow maintenance and lubrication of the ring. The purpose of a bushing is similar to that of a bronze bearing, and the thickness is generally smaller than that of a bronze bushing. It will serve as a guide for the rotation of the shaft relative to a fixed reference, where minimum dimensions are necessary. The bushing wears slowly and takes up very little time. Some versions are maintenance free and can be run dry. We stock large size of bushings with same day dispatch and worldwide exporter.

Low Friction Plain Bushing For Bearings

Quality Boundary Lubrication Bearing,Pom Lined Plain Dry Bearing

Product Quality Index

Energy Generation

Oil-free lubrication bearing, as the name implies, refers to the use of before or during the use of lubricants can also be normal operation, and play a good effect of friction reduction bearings. Oil-free lubrication bearing belongs to a kind of sliding bearing. General sliding bearings need to add lubricant, grease and other lubricants before work, so as to form a lubricating film on the friction surface and play an effective role in lubrication, while oil-free slide bearings made of self-lubricating materials or pre-filled with lubricant after sealing up can be used for a long time, without adding lubricant during the work process.

Bushing Type

Oil-free lubrication bearing from the product structure is divided into solid inlay bearing, composite bearing, oil bearing, new single lubrication material.

Solid inlay bearings

Common is the solid lubrication material graphite (black lead), polytetrafluoroethylene (PTFE), molybdenum disulfide, etc. using the inlay process buried in high force brass, tin bronze, aluminum bronze, cast iron or GCr15 and other alloy materials. It breaks through the limitations of general sliding bearings relying on oil film lubrication. In the process of use, the solid lubrication is made to rub with the shaft through frictional heat, forming the excellent condition of oil and powder coexisting lubrication, which not only protects the shaft from wear, but also makes the solid lubrication characteristics eternal. The hardness of high force brass is twice as high as the general brass bushing, and the wear resistance is twice as high, and the bearing capacity is high.

Composite Bearings

The common composite bearing is made by combining two layers of steel plate and copper powder layer (bimetal), or three layers of steel plate, copper powder layer and self-lubricating material (PTFE, PEEK, POM) + filling material. It adopts high temperature sintering process to bond the self-lubricating material on the steel plate, which not only ensures the frictional wear performance of the working surface of the product, but also ensures the structural stability and load-bearing capacity of the bearing.

Oil-bearing

Oil-containing bearings are made of metal materials, and the bearings are oiled and sealed with lubricating oil, so that they can be used without adding oil to achieve the effect of “self-lubrication”. Since the bearing contains oil lubricant, it has good lubrication and avoids oiling and maintenance work.

New Single Lubricant Bearings

New single-lubricated material bearings are common resin, ceramic, tungsten carbide bearings, etc., and new materials are constantly being developed, but these bearings may have high costs, narrow application area, etc., can not be widely promoted to replace rolling bearings.

Bearing Bushing Advantage

Oil-free lubrication or oil-less lubrication, is suitable for places where it is impossible or difficult to refuel, can be used without maintenance or less maintenance, and also eliminates the risk caused by insufficient oil supply.

No oil supply device required

No oil supply device is required, and oiling can be eliminated during operation, thus saving significant installation and operation costs. Oil-free can make the design and structure, etc. significantly simplified, reducing costs and saving design time.

Green and Environmentally Friendly

No need for waste oil recycling treatment, which is good for environmental protection.

Reduced requirements for grinding parts

The hardness requirement for grinding shafts is low, and shafts without tempering treatment can be used, thus reducing the difficulty of machining related parts.

High and low-temperature resistance

High and low-temperature resistance, some products can be used at temperatures from -200℃ to 600℃.

Applications

Engineering and construction machinery

Crank arm bushings, guide wheel bushings, oil cylinders, gear oil pumps, driven wheels, driven wheels, rotary tables, grapple joints, and other parts in excavators, bulldozers, scrapers, rotary drilling rigs, lifting machines, handlers, forklifts, and other machinery.

Plastic and rubber machinery

Injection molding machine, tire curing machine, blowing machine, molding machine, and other machinery such as crosshead, locking mold, oil cylinder, machine hinge, operating mechanism, and other parts.

Automobile parts

Transmission, differential, clutch, balance axle, connecting rod bushings, throttle body, tension wheel, turbocharger, injection pump, idler pulley, oil pump, rocker arm bushings, shock absorber, steering machine, steering resistance pump, hinge, wiper, and other parts.

Office equipment fitness equipment

Copiers, printers, fitness equipment, sewing machines and other machinery requiring transmission or reciprocating motion parts.

Mould guide bush

Parts of the mold such as guide, diagonal fit, positioning, guide rail, etc.

Food and pharmaceutical machinery

Because of the high requirements for the production environment, the rotating and reciprocating parts of food machinery and pharmaceutical machinery.

Failure mode

Abrasive particle wear

Some of the hard particles that enter the bearing gap rotate with the shaft and act as abrasive to the bearing surface.

Scratching

The hard particles entering the bearing gap or the rough microscopic contour spikes on the surface of the shaft diameter scratch the bearing surface with linear scars.

Gluing

When the transient temperature rise is too high, the load is too large, when the oil film rupture or insufficient oil supply, bearing surface material adhesion and migration occurs, causing bearing damage.

Fatigue spalling

Under the repeated action of the load, the bearing surface fatigue cracks perpendicular to the sliding direction, after the expansion of the bearing material spalling

Corrosion

Lubricant in use constantly oxidation, the acid generated on the bearing material has corrosion, material corrosion is easy to form pitting spalling. There is also cavitation fluid erosion electric erosion.

Feature Description

Oil-free lubrication or oil less lubrication is suitable for places where it is impossible or difficult to add oil and to avoid mixing of lubricating oil as well as no or less maintenance during use and also eliminates the risk caused by insufficient oil supply. No oiling device is required, no oiling device is required, no oiling is required during operation, and therefore significant installation and operating costs can be saved. Oil-free can make the design and structure greatly simplified, reducing costs and saving design time Green, no need for waste oil, recycling, and environmental protection. Reduced requirements for grinding parts, low hardness requirements for grinding shafts, untempered shafts can be used, thus reducing the difficulty of processing related parts. High and low temperature resistance, high and low temperature resistance; some products are applicable temperature -200℃ to 600℃. Application of oil-free lubrication bearings: construction machinery; excavators, bulldozers, scrapers, rotary drilling rigs, lifting machinery, conveyors, forklifts, etc. Machinery crank arm bushings, guide wheel bushings, oil cylinders, gear oil pumps, driven wheels, driven wheels, rotary tables, grapple joints and other parts. Plastic and rubber machinery: injection molding machine; tire vulcanizing machine; blowing machine; forming machine and other machinery of crosshead locking, oil cylinder? Machine hinge? Operating mechanism and other parts. Auto parts shifter, differential, clutch, balance axle linkage bushing, throttle body, tensioner wheel, turbocharger, injection pump, idler wheel, oil pump, rocker arm bushing? Shock absorber, steering machine, steering resistance pump? Hinges, wipers and other parts. Office equipment fitness equipment: copiers, printers, fitness equipment, sewing machines and other machinery that require transmission or reciprocating motion parts. Mold guide bush Mold guide, diagonal fit, positioning, guide rail and other parts of the food and pharmaceutical machinery. Because of the high requirements of the production environment: food machinery; pharmaceutical machinery rotation and reciprocating motion parts without oil lubrication bearing failure mode Abrasive wear The hard particles that enter the bearing gap some of which rotate with the shaft? Abrasive effect on the bearing surface. Scratching The hard particles entering the bearing gap or the rough surface of the shaft diameter microscopic profile spikes, in the bearing surface scratches a linear scar. Gluing when the instantaneous temperature rise is too high load is too large oil film rupture or insufficient oil supply bearing surface material adhesion and migration caused by bearing damage. Fatigue spalling in the load has to be repeatedly under the action of the bearing surface with the sliding direction of the fatigue crack expansion caused by bearing material spalling corrosion lubricant in use constantly oxidation generated by the acidic material on the bearing material has corrosion material corrosion prone to the formation of point-like spalling.

Quality, Well-made Bearings, and Bushings. Experienced Manufacturer Manufacturing Sliding Bearings.

We offer a wide range of high-performance bearing materials, services, and solutions.

Bearings & Bushings – Composites PTFE bushing and Composites POM bushing.

Composite Bushings & Bearings

POM composite bushings are referred to as prelubricated because their material is designed to operate with marginal lubrication.

Composite materials have been the go-to choice for bearing and bushing applications for the better part of the last century.

View Our Products. Get A Quote Today. 100% QualityExperienced Manufacturer Manufacturing Sliding Bearing Guaranteed.

Worldwide On-time Shipping. View Our Products. Contact Us Today. Extreme Stable & Durable. Oilless Self-lubricating. High-end Production Lines.Application Scenarios

Intelligent Mechanical Support High-Quality Guarantee, Quality Guaranteed Worldwide On-time Shipping

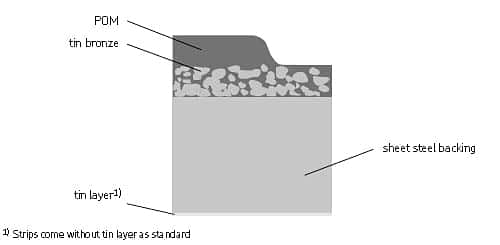

- Metal-Polymer Composite Self-lubricating Bushing Material Steel Back + Porous Bronze Sinter +PTFE +Lead

- Metal-Polymer Composite Bushing Material Steel Back + Porous Bronze Sinter +POM with Lubrication Indents

This range of fiber-reinforced composite bearing bushing material products typically includes Tax, steel rolled bushing and a variety of low friction wear resistant bearing liners..DX Bushing, POM Plastic Bushes, Lead Free Bushings, Low Friction Bearing Bush, Composite Bushings Bearing Online.

We manufacturer composite bushing bearing tailored to your individual needs.

The low friction bearing bushing

Self-lubricating bearings belong to sliding bearings, you can greatly reduce friction losses and surface wear, self-lubricating bearings can be designed to achieve smooth work, self-lubricating, reliable, oil-free bearings, no noise. Liquid lubrication conditions, isolated lubricant does not directly contact the sliding surface for impact absorption.

Self-lubricating bearing belongs to sliding bearing, you can greatly reduce friction loss and surface wear, self-lubricating bearing design can achieve smooth work, self-lubricating, reliable, oil-free bearing, no noise. Liquid lubrication conditions, isolated lubricant does not directly contact the sliding surface for impact absorption.

Self-lubricating bearings advantages and characteristics.

Self-lubricating bearings are also widely used, such as tobacco machinery, automobiles, printing presses, micro-motors, textile machines, motorcycles and agricultural and forestry machinery and so on. Self-lubricating bearings have their own advantages and characteristics.

1, there is a moderate amount of elasticity, can distribute the stress in a wider contact surface, to improve the bearing capacity.

2, self-lubricating bearings have good wear resistance, small coefficient of friction, long service life.

3、No oil lubrication or less oil lubrication, suitable for places where it is impossible to refuel or very difficult to refuel, can be used without maintenance or less maintenance.

4, static and dynamic friction coefficient is similar, can eliminate the crawling at low speed, so as to ensure the working accuracy of the machinery.

5, self-lubricating bearings for grinding shaft hardness requirements are low, without tempering treatment of the shaft can be used, thereby reducing the processing difficulties of the relevant parts.

Self-lubricating bearing

6、Self-lubricating bearings can form a transfer film during operation, which can protect the shaft of the grinding, no bite shaft phenomenon.

7、It can make the machinery reduce vibration, reduce noise, prevent pollution and improve labor conditions.

8、Thin-walled structure, light weight, can reduce the volume of machinery.

9、The back of the steel can be plated with a variety of metals, can be used in corrosive media; has been widely used in the sliding parts of various machinery, such as.

Printing machines, micro-motors, textile machines, tobacco machinery, automobiles, motorcycles and agricultural and forestry machinery, etc..

But the greater the starting friction. The shaft part of the bearing is called the shaft diameter part, called bush and shaft diameter together to go. In order to improve the casting of the inner surface layer of the friction material of the friction bearing surface properties called bearing lining.

Bearing and bearing lining materials are collectively referred to as bearing materials. Bearing applications are generally in low speed and heavy conditions under loading conditions, maintenance and lubrication or difficult operating areas.

POM type bearing bushing material

POM type material is filled with tetrafluoro-modified polyacetal plastic as the surface layer of the three-layer composite self-lubricating material, it is a benign boundary lubrication material, so it is especially suitable for high load and low speed under the rotary motion, swing motion and often under load opening and closing and not easy to form hydrodynamic lubrication of bearings, thrust washers, sliders, ball seats and other friction parts.

POM Bushes can make full use of trace amounts of grease and can be maintained for a long time without oiling under boundary lubrication lubrication conditions. Under completely oil-free lubrication conditions, POM Bushes have lower frictional performance and allowable PV values, so they are usually rolled out on the plastic surface with oil storage pits and coated with lithium-based lubricating grease or silicone grease during assembly.

1. Modified paraformaldehyde

2. Spherical bronze powder

3. Steel backing

4. Copper/tin plating layer

Large Diameter Composite Bushings Now Available

Composite Self-Lubricating Bushings, The series of products can also be selected according to the different working conditions of different substrate materials, such as: bronze substrate, stainless steel substrate, and “lead-free” and other formulations of products. Environmentally friendly lead-free products are available in orange, orange and blue colors.

Machinability of composite bearing materials

Beautifully crafted leather products.

FASTER – BETTER – SAFER

POM composite bushing, Bronze sliding bearings, composite bushings and engineering plastics: POM bearings. With the exception of the sliding layer, composite bushings can be machined using conventional methods.

If the bushing is required to have a smaller width than the standard size, this can be easily achieved by turning. It is also possible to drill lubrication holes. However, any burrs, especially on the sliding surface, must be removed.

Strips can be bent, pressed, cut or drilled to suit individual applications. When cutting or drilling, we recommend doing so from the sliding surface side to avoid creating burrs on the sliding layer.

Any metal surfaces exposed as a result of machining should be protected to prevent corrosion.

Machining the bore of PTFE composite bushings

The PTFE composite bushing is ready for installation. Any adjustment to the bore (i.e., sliding surface) will reduce the life of the bushing and should only be done in special circumstances. If it is necessary to machine the bore, it should be resized and calibrated.

Machining the bore of POM composite bushings

Bushings made of POM composite are ready for installation. However, if necessary, the bore of the bushing can be machined to size while mounted in its housing.

POM Composite Bushings, Self-lubricating bronze bushings, Composite Bushings Sourcing Service

We will immediately select the right high-quality composite bushings products suitable for you. Quick Response

Once we receive your request, we will contact you, and the qualified composite bushings will be recommended for your application.

POM Composite bushings surface polymer is resistant to chemical corrosion, so its corrosion resistance mainly depends on the steel back and the outer plating layer. The surface of the steel back is plated with copper or tin, which can effectively prevent atmospheric corrosion; if working in a corrosive medium, the steel back can be galvanized.

POM composite bushings are called pre-lubricated because their material is designed to operate with marginal lubrication. This type of bushing effectively fills the space between fully lubricated and dry sliding bushes. VIIPLUS offers a wide range of POM straight composite bushings

BUSHINGS SELECTED

POM Composite Bushings-High Quality, Factory Price

Materials

Steel support with a layer of sintered tin / bronze pores filled and covered with a layer of POM composite

Pom composite bushing Material

Discover the complete POM composite bushings portfolio

POM composite bushings Designs

POM composite sleeves are available as straight sleeves in metric and inch sizes. Pockets in the sliding surface make these sleeves suitable for applications requiring minimal maintenance in harsh operating conditions, for example in a polluted environment where grease cannot be supplied continuously or frequently.Therefore, the grease tanks must be filled before installation. Despite their compact design, POM composite bushings can withstand heavy radial loads and are less sensitive to misalignment. They are suitable for slow and linear rotation or swing movements.

POM composite bushings Advantages

- Maintenance-free operation

- Very good friction properties

- High load capacity

- High sliding speed

- Small operating game

POM composite bushings Technical Data

| Maximum load(P) Static Load | 250N/mm² |

| Dynamic load | 150N/mm² |

| Max. Speed V grease lubrication | 2.5m/s |

| Max PV grease lubrication | 2.8N/mm²・m/s |

| frictional coefficient (μ) grease lubrication | 0.05~0.25 |

| Working Temperature | -40℃~+130℃ |

| Thermal Conductivity | 4W/m・K |

| Coefficient of Linear Expansion | 12×10-6/K |

POM composite bushings Lubrication

POM composite bushing plain bearings are designed for extreme lubrication applications. The sliding surface of these POM composite plain bearings contains lubricant containers that must be filled before installation. It is not necessary to lubricate these POM composite bushing, but the presence of grease can significantly extend the life of the POM composite bushing. Grease can be applied regularly to protect the mating surface from corrosion.

POM composite bushings operation performance

- Oil lubricated Good

- Grease lubricated Very Well

- Water lubricated Poor

- Process fluid lubricated Poor

POM composite bushings Dimensions

Metric (mm) Imperial (inch) POM Composite Bushing

Shaft and housing tolerances (Design of POM composite bushing arrangements)

- Housing ØH7

- Shaft tolerance h8

POM composite bushings Availability

POM composite bushing available in standard dimensions

- Cylindrical bushes

- Thrust washers

- Sliding plates

Metric bearings and imperial POM composite bushing bushings on order: standard bearings shapes in special dimensions, half bushings, special shapes obtained by stamping, bearings with positioning notches, lubricant holes and machined grooves, custom bearings designs

POM Composite Bushings Application

POM composite bushings are suitable for applications where a sliding material with self-lubricating properties is required.

- Automotive/Transportation

- Railroad

- Aerospace

- Material Handling Equipment

- Construction Machinery

Typical Application

Recommended for applications involving intermittent operation or boundary lubrication.

Automotive: joints, pin assemblies, propeller hinges, steering joints, and others, rear chassis joints and hinges.

Machine tools: spindles in drills, grinders, and milling machines and slide guide plates in multi-piston presses.

Agricultural equipment: gearboxes, clutch assemblies, bale extensions, and swivel castors for bale accumulators, front axle articulated bearings, steering wheel idler bearings and steering knuckle roller bearings …

pom bearing

“zero option bushings, sleeve bearing, composite bearings.”