We Make The Bronze Sliding Plate Grade & Materials Mix To Your Specifications.

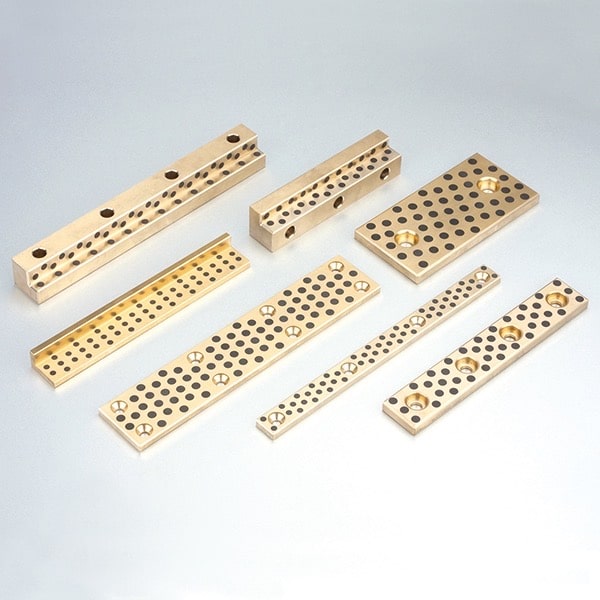

Graphite Impregnated Plates – Volume & Custom Production, Slide Bearing Plate, Graphite Plate – Slide Bushing Bearings Hi Temp Applications

Customized Solutions,Slide Bearing Plate, Graphite Plate – High Temperature Resistance

We Offer Custom Self-lubricating Graphite Product & Manufacturing. Slide Plates -NAAMS Standard Copper Alloy + Graphite (Embedded) – Know More. We’ve worked in demanding industries such as chemical processing, energy, and health care, and we are confident we can support your operations as well.

Bronze Plates company

Self lubricating bronze plates

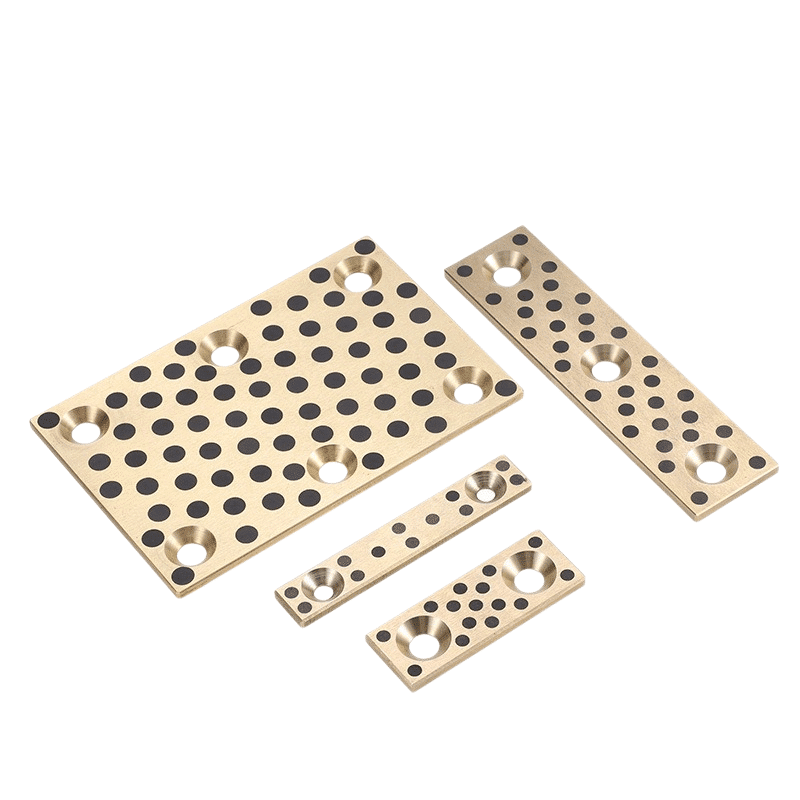

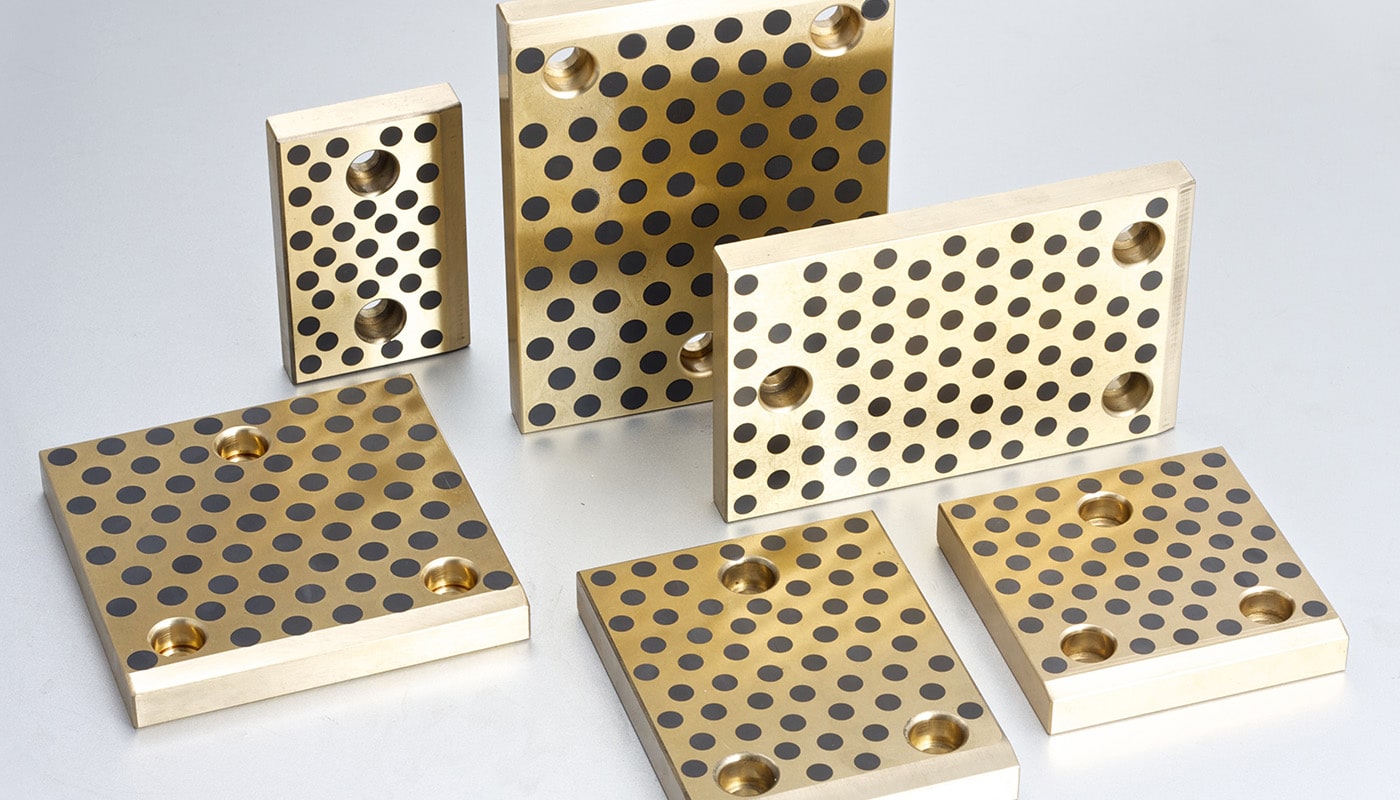

We manufacture machined bronze wear plates to meet the exacting requirements and specifications provided by our customers. All of our wear plates are custom manufactured to customer designs using high quality bronze material in either continuous or centrifugal casting. Manufacturer Of Wear Plates, Custom Wear Plate Solutions. Expert Manufacturer. Download Brochure. One-stop service. Fast Delivery. Quality Assurance. The bronze slide plate is manufactured with machined holes and/or grooves into which graphite is inserted. The graphite plugged act as the lubricant.

Product Quality Index

Energy Generation

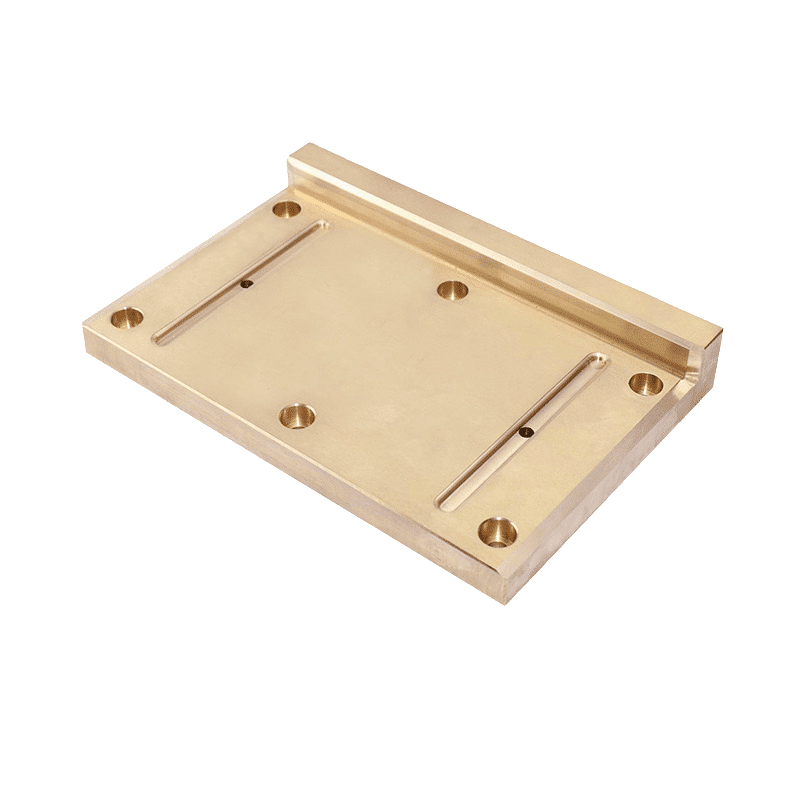

Bronze Wear Plates with External Lubrication

Beautifully crafted leather products.

The bronze plate has machined holes and/or oil grooves into which graphite is inserted. These graphite plugs act as a lubricant between the shaft and the plate. The graphite plugs provide a slippery coating that acts as a constant, reliable lubrication between the surfaces.

This type of bronze wear slide plate is commonly marketed as SelfLube, Oilless Plate plugged graphite, graphitized or simply self-lubricating. Bronze is the ideal metal for the manufacture of wear plates because of its low coefficient of friction compared to other metals, which extends the service life of the slide plate.

A wide range of bronze alloys, high tensile brass and aluminum bronze are stocked in rectangular and square slider materials. In addition, we offer fast turnaround for alloys and sizes not currently in stock to ensure the fastest delivery times for bronze wear plates on the market.

Bronze Wear Plate Standard Metric Size

If your company works in steel, pipeline or aluminum plants, chemical companies, mining or the military, then you need wear plates! Wear plates are used to guide and control linear motion when there is gravity to contend with. Although they were originally developed for metal stamping dies, wear plates have many other uses in molds, special machines and heavy equipment. We produce wear plates that conform to all industry standards (VDI, JIS, NAAMS, SMC). Our wear plates are available in a wide range of standard inch and metric sizes, in steel or aluminum bronze, with or without self-lubricating graphite. If a standard wear plate won’t do, we can economically custom configure it for a special size, hole pattern or graphite pattern. Also, don’t forget to check out our wear bar section. Wearstrips are a similar product, but available in a wider range of sizes. Need a wear plate? Request a quote today, or contact us for more information!

about the company

Manufacturer of Precision Mold & Die Components Plate

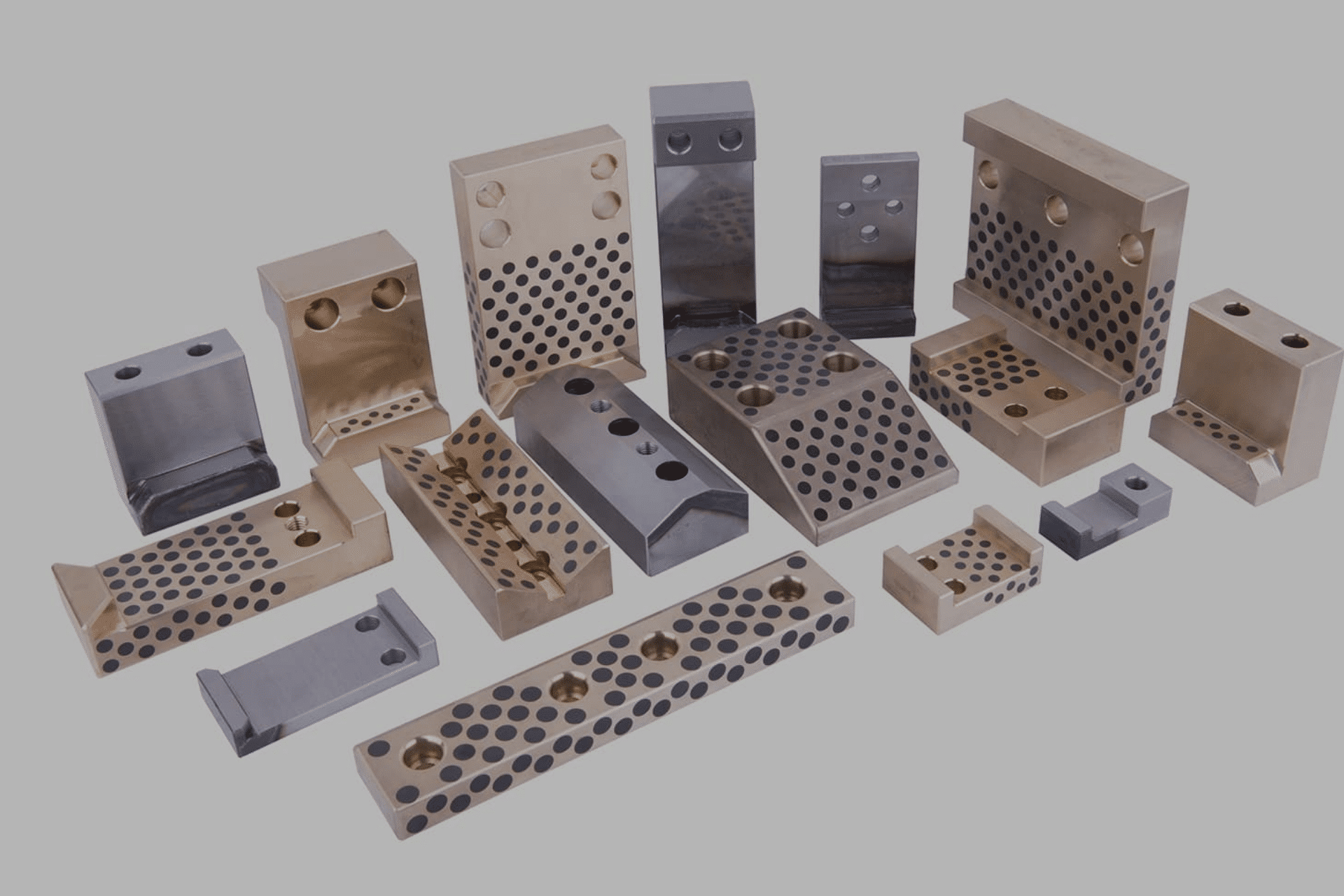

Our line of wear slide plates includes our line of bronze plates that are designed and manufactured to operate with external lubrication. We offer a high quality bronze alloy, as well as a large number of compatible lubricants on the market, allowing these bronze plates to be used in a wide range of operating conditions. The main function of the bronze wear strips is to act as slide bearings to guide and control the movement of metal stamping dies, moulds, special machines and all types of heavy equipment. These are ideal for extrusion sizing plates. Made of solid bronze with self-lubricating graphite plugged, the graphite plugged gibs are available in a broad range of standard inch and metric sizes. And, if a standard gib won’t do the job, we can economically make custom graphite plugged gibs in just about any size. Also, additional types of gibs, mainly related to metal stamping dies, may be found in the Guide Components section. More information on our self-lubricating bronze series of bronze graphite wear plates and oilless wear plates which are self lubricating. We manufacture a wide range of bronze slide wear plate formats and shapes, including.

Product Quality Index

Energy Generation

Bronze alloys for wear plates

factory price

Guide Components, Slide Bronze Plate

Beautifully crafted leather products.

Primarily used for metal stamping dies, but occasionally for other applications (molds and special machines), the guide parts are very robust. They are ideal for applications where very high loads may be encountered. We have been producing machined wear plates, bushings and other copper parts for equipment manufacturers. Below you will see some of the plates we have recently produced for our customers.

- Guided parts include.

- Cam Gibs

- Gib Blocks and Lids

- Keeper Plates

- Center Keys and Guides

- U and V Blocks

They are made of steel or aluminum bronze with self-lubricating graphite and are available in various inch and metric (NAAMS) sizes. Slide plate graphite suppliers, we offer products used in high-temperature applications, often as an alternative to PTFE slide plates. Manufacturers like viiplus provide various options. we offers wholesale graphite slide plates. We offers a range of extruded and bronze graphite plates, bushes, and thrust washer with characteristics like high-temperature resistance and electrical conductivity. Industrial needs for self-lubricating and durable sliding solutions.

Slide Bearing Plate for

Piping Technology & Products

Slide bearing plates are a very cost-effective way of providing for movement of mechanical systems. We manufacturing slide bearing plates for a variety of applications including support of piping, heavy equipment such as pressure vessels, and structural steel members. Graphite Products – China – Global Supply. Local production of slide plate series linear motion system. Shorter delivery time, imported quality, factory price/ Leading Supplier of Quality Graphite Plate Products, Graphite Block, Slide Plate. Competitive Price. Graphite Supplier. Top Quality Assured. features: high strength, easy of precise machining, excellent self-lubricating material. We use state-of-the-art machining and turning centers to manufacture bronze wear slide plates in large sizes that meet our customers’ exacting specifications, ensuring industry-leading performance, durability and wear resistance. Our machining process covers all aspects of wear plate fabrication, including lubrication grooves and other necessary configurations. We offer the flexibility to manufacture single plates, as well as larger batches or entire series.

Slide bearing plate – plugged graphite

slide bearing plate is best suited for high loads, low-velocity applications and in places where the use of oil or grease is undesirable or unfeasible. Bronze sliding plates impregnated with graphite will also handle high temperatures.

Slide bearings plates are used in a wide range of applications, petrochemical plants, heavy machinery, pipelines, buildings and bridge!

Slide bearing bronze plate – For High Temp Applications

Slide bearing plate is the Solution for Bearing Problems in High Temp Applications. Sliding bronze plate have been developed for high load, low speed applications and are made of rotational cast high-strength bronze Reduced costs & downtime. Increased productivity. Services: Custom Design, Engineering Support. Graphite impregnated bronze bearing plates Low Friction Slide Plates Made to order from China.

Sliding Bronze Graphite Wear Plate Manufacturing, Applicable Slide Plate, Optimized.

Slide Bearing Plate manufacturers & suppliers, When you need demanding automation machines or electromechanical equipment, we know there is no one size fits all solution. we delivers custom sliding plate and oilless bearings engineering to meet your non-standard requirements. You create the oilless plate that move us forward. We create the finished bronze wear parts that powers your production. For every project that comes through our facilities, we committed to excellence. We have a dedicated quality control system with documented standards and procedures, and we comply with strict quality standards.

A slide plate is a mold component that slides in a direction perpendicular to or at a certain angle to the opening and closing direction of the mold. The slide plate is used when the structure of the product is such that the mold cannot be released properly without the slide plate. The material itself has the appropriate hardness and wear resistance to withstand the friction of the movement.

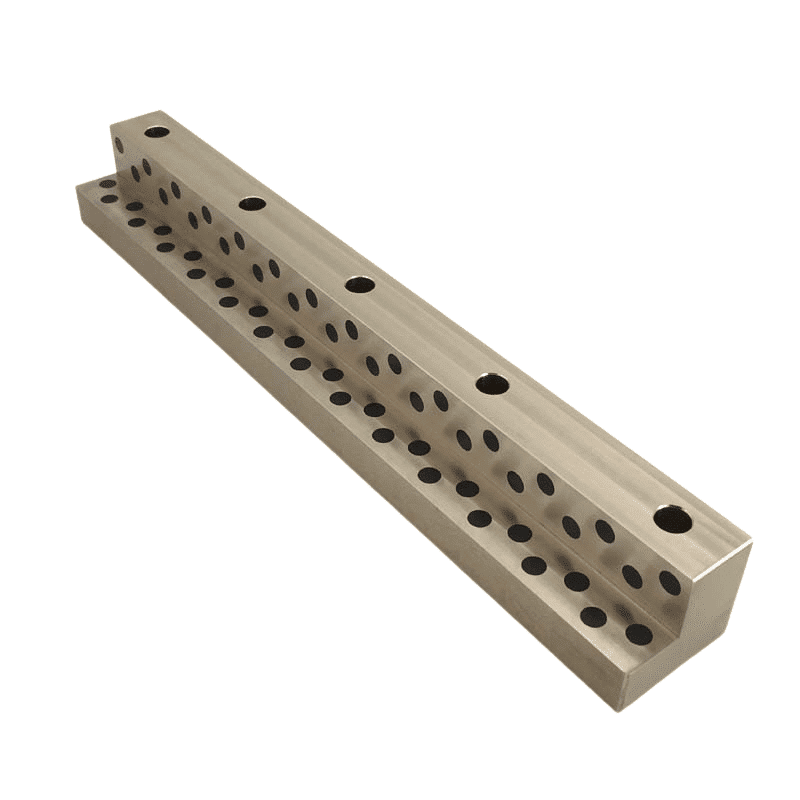

Bronze Sliding Plate

Bronze Sliding Plate is mainly used as a linear bearing to guide and control the movement of metal stamping dies, molds, special machines and all kinds of heavy equipment. They are ideal for extrusion sizing plates. Bronze Sliding Plates are available in a large number of standard inch and metric sizes, including NAAMS sizes. They are made of solid aluminum bronze and can be ordered with or without self-lubricating graphite.

If you are looking for a certain size of Bronze Sliding Plate with a standard hole, please see our catalog page for any size of wear strip. If a standard wear strip does not meet the requirements, we can economically customize special size Bronze Sliding Plate, special mounting hole types, special graphite types, and special flange bearings. Also, please see our section on Bronze Sliding Plate, a similar product often used in metal stamping dies. We take pride in using premium materials for our products. The bronze wear plate, or its equivalent, is our material of choice for certain applications, offering unparalleled wear resistance and longevity.

Die plates grease with graphite, aluminum bronze plate.

Start Your Oilless Graphite Sliding Plate Project Today!

Graphite Sliding Plates, Die Plate, Global Supplier, Self-lubricating Bronze Wear Plate. A graphite slide plate is made by inserting a special solid lubricant into a suitable position. Lubricated by a metal bronze base supporting the load and inlaid with a solid lubricant, it exhibits excellent self-lubricating durability even under harsh conditions. Products with copper alloy as the substrate, making full use of the wear resistance of copper and the self-lubricating properties of solid lubricants, can be processed in the friction surface of a variety of oil grooves and oil holes and inlay solid lubricants, can adapt to different environmental working conditions, in the process of use without refueling maintenance. Such as steam locomotive production line, home appliances, automobiles and other stamping and stamping dies, large metal extrusion equipment, plumbing arc doors, etc. We provide standard parts of automobile dies such as slanting wedge, concave and convex V-block, L-type guide plate, etc.

Graphite Filled Bronze Slide Plate, Standard Components for Press Die. Slide Components.

Beautifully crafted leather products.

We develop and offer mechanical components and standardized machine slide graphite parts for factory automation (FA) and automated production systems. Standardized mechanical components, the factory automation business is our core business . Furthermore ,we offer an additional platform where customers can search for graphite slide plate products, compare and get quotations, and download free CAD files. High-quality bronze graphite slide plates for smooth motion. Copper Alloy High Surface Lubricating Type Skateboard Auto Mold Plate!

High-strength Brass Bearings with Embedded Solid Lubricant:

Delve into our comprehensive online catalog and explore our range of brass bearings embedded with solid lubricant. These are not just any bearings; they are designed to offer superior strength and durability, ensuring smooth and efficient operation in various environments.

Graphite Slide Plate Design

Oilless Graphite Sliding Plate, Precision Die Plates From China- Die Plate – bronzelube.com

Graphite Slide Plate Feature

- Firstly, Sliding plate most suitable for must often add lubricating oil position, reciprocating motion or frequent start and stop position, and difficult to form oil film position.

- secondly, Bronze sliding Plate can be used in self-lubricating state without refueling device, which can shorten the assembly period, reduce oil pollution and beautify the environment.

- In addition, Graphite slide plates have good bite resistance.

Graphite Slide Plate Type

- Oilless sliding Plate – NAAMS Standard

- Graphite thin thickness Slide Plate – Copper Alloy 5mm

- Sliding plate plugged graphite – Copper Alloy 20mm· Two Bolt Holes, Three Bolt Holes, Four Bolt Holes, Six Bolt Self-lubricating Holes

- Graphite Slide Plate – Copper Alloy 10mm· Two Bolt Holes, Four Bolt Holes

Graphite Bronze Slide Plate Online

Sliding Plate According, Bronze With Solid Lubricant, Standard L-Shaped Plates, Flat Plates, Self Lubricating! Retaining Plate, Bronze With Solid Lubricant, Typical Application: Graphite slide plate is installed in the leading position of mould closing, so that it has the guiding lubrication and certain compressive performance in the upper and lower closing.Good self-lubrication performance, no need of refueling lubrication. Graphite Sliding Plate Material Copper Alloy CuZn25Al5Mn4Fe3 ASTM B505+ Graphite Insert Sliding Plate Sliding Faces Ground! Oil Free Cooper Alloy Slide Plates Solid Lubricant Brass Plate Graphite Bearing Pads Wear Plate Bronze!

Precision Graphite Slide Plates: As a result bronze graphite sliding plate are used in a range of industries by some of the biggest companies across the globe.

Top Quality. Sizing Plate: Grease with Graphite High-Quality Graphite Slide Plate For Customer’s Needs.

Custom Made: Whatever Standard or Non-standard Graphite Slide Plate all Meet Customer’s Request.

Custom Sliding Plate for highly specialized applications

Graphite Sliding Plate Global Shipping. Whether you need a partner to work from existing specifications or you’re looking for design and engineering support, we meets you where you are to create sliding lubricating plate that’s truly custom. Standard Sliding Plate: Various standard slide plate and oilless bushing are available. Check model numbers and sliding plate dimensions, and contact with us get a free quote. Please note that some items may not be listed. Refer to the electronic catalog for more information. Order in many variants in the online shop. Fast delivery ✓ Fair prices ✓ Select and …Maintenance-free sliding plates, Oilless Self-Lubricating Bronze Slide Bearing Plate with Solid Graphite Inserted!

Graphite Slide Plate Custom Design.

Graphite Slide Plate Stock In China.

Aluminum Bronze Slide Plate Plugged Graphite -CuAl10Fe5Ni5, Slide Plate bronze material

Aluminum bronze, specifically CuAl10Fe5Ni5, is a high-strength, wear-resistant material widely used in various industries. This type of bronze, also known as nickel aluminum bronze, is composed of copper, aluminum (10%), iron (5%), nickel (5%), and the remaining part being other elements. This composition gives it excellent mechanical properties, including superior resistance to corrosion and wear.

A slide plate made from this material would be particularly durable and effective in applications involving heavy loads and friction. The high strength and toughness of the alloy make it ideal for these conditions, and its corrosion resistance means it will perform well even in harsh or marine environments.

When you mention “plugged graphite,” it seems you are referring to a process of incorporating graphite into the bronze material. This is often done to enhance the self-lubricating properties of the material. In this case, holes are drilled into the surface of the bronze slide plate, and then these holes are filled with graphite plugs.

The graphite acts as a dry lubricant, reducing friction and wear on the slide plate. When the plate is in use, the heat and pressure cause the graphite to be released onto the surface, helping to lubricate the contact areas. This is particularly beneficial in applications where traditional lubrication methods may be difficult or impossible.

In summary, a slide plate made of aluminum bronze with plugged graphite combines the strength, toughness, and corrosion resistance of the bronze alloy with the self-lubricating properties of graphite. It would be an excellent choice for applications involving high loads, friction, or challenging environmental conditions.

Graphite slide plate is a high-performance guiding part used to ensure accurate positioning of tools in CNC machining. It has a low coefficient of friction, high thermal conductivity and wear resistance, which can effectively improve machining efficiency and machining accuracy.

Features of Graphite slide plate :

High precision: Graphite slide plate adopts advanced processing technology and has high machining precision, which can ensure accurate positioning of tools in the machining process.

Low friction: Graphite slide plate has low friction coefficient, which can reduce the friction loss during machining and improve the machining efficiency.

High thermal conductivity: graphite slider has high thermal conductivity, which can effectively reduce the heat accumulation during machining and prevent tool wear.

Wear resistance: Graphite slider has wear resistance, which can withstand long time use and ensure the service life of the tool.

High stability: Graphite slider has high stability, which can ensure the stability of the tool in the machining process and improve the machining accuracy.

Application areas:

Graphite slide plate is widely used in CNC machining centers, engraving machines, robots and other fields, which can ensure accurate positioning of tools and improve machining efficiency and machining accuracy.

Graphite slide plate is a kind of high performance guiding parts with low friction, high thermal conductivity, wear resistance and high stability, which can effectively improve the machining efficiency and machining accuracy, and is an indispensable and important part of CNC machining.

Translated with www.DeepL.com/Translator (free version)

Bronze Wear Plates & Graphite Plugs, Bronze Plate CuSn10P

Bronze Plate CuSn10P is a type of bronze alloy that is composed of copper (Cu), tin (Sn), and phosphorus (P).

The composition of CuSn10P typically consists of 88-90% copper, 9-11% tin, and 0.15-0.35% phosphorus. This particular bronze alloy is known for its excellent wear resistance, high strength, and good corrosion resistance.

Bronze Plate CuSn10P is commonly used in applications such as bearings, bushings, gears, and other mechanical parts that require high strength and wear resistance. It is also used in marine applications due to its good corrosion resistance in saltwater environments.

Bronze Plate CuSn10P is a versatile and reliable material that is suitable for a variety of industrial and mechanical applications.

Bronze graphite plate CuSn10P is a type of bronze alloy that is reinforced with graphite particles. This material has a unique combination of mechanical properties that make it ideal for use in a wide range of industrial applications.

The composition of CuSn10P bronze graphite plate typically consists of 88-90% copper, 9-11% tin, 0.15-0.35% phosphorus, and 1-2% graphite. The addition of graphite particles to the bronze alloy improves its lubrication properties, making it more resistant to wear and reducing the amount of friction between moving parts.

One of the key benefits of using bronze graphite plate CuSn10P is its excellent wear resistance. The combination of bronze and graphite provides a self-lubricating surface that can withstand heavy loads and high temperatures. This makes it an ideal material for use in bearings, bushings, and other mechanical parts that require high strength and durability.

In addition to its wear resistance, bronze graphite plate CuSn10P also exhibits good corrosion resistance. It can withstand exposure to harsh environments, including saltwater and acidic solutions, without deteriorating or losing its mechanical properties. This makes it a popular material for marine applications, as well as for use in chemical processing and other industrial settings.

Overall, bronze graphite plate CuSn10P is a versatile and reliable material that offers a unique combination of mechanical properties. Its excellent wear resistance and self-lubricating properties make it ideal for use in a variety of mechanical and industrial applications, while its corrosion resistance makes it suitable for use in harsh environments. If you need a material that can withstand heavy loads and high temperatures while maintaining its strength and durability, bronze graphite plate CuSn10P is an excellent choice.

Bronze Wear Plates & Graphite Plugs, Wear Plates come in a variety of sizes. They come complete with self-lubricating graphite and are made of aluminum bronze. Graphite physical properties

Slide Bearing Plates for Pipeline Supports

| Permissible load (N/mm2) | Permissible slip velocity (m·min) | Max. PV value (N/mm2·m/min) | specific gravity | Parent metal hardness (HB) | Tensile Strength (N/mm2) |

| 50 | 24 | 108 | 8.2 | >210 | 600 |

*Graphite slide plate typical application

Graphite slide plate is especially suitable for high load, low speed and intermittent swing operating conditions.Such as automobile cover die, metal stamping die, injection molding machinery and metallurgical equipment.

Metallic sliding plate having been used widely: The Sliding plate series are self-lubricating plate composed of high strength brass alloy bases made with advanced casting technology and embedded solid lubricants. They may be combined with various types of solid lubricants according to the conditions of use. Sliding Plate Features: No lubrication is required for maintenance. Exhibits high performance under high loads and low speed operation. Exhibits excellent wear resistance in applications where oil film is rarely produced, such as reciprocating motion, oscillation, frequent starts and stops, etc. Excellent chemical and corrosion resistance.

- Bronzelube’s guide components include:

- Cam Gibs

- Gib Blocks and Lids

- Keeper Plates

- Center Keys and Guides

- U and V Blocks

They are made of either steel or aluminum bronze with self-lubricating graphite and are available in a variety of inch and metric (NAAMS) size: Standard sliding plates are available in a variety of sizes!

Self-lubricating bronze water plate

Self-lubricating bronze wear plate is also called sliding bearing plate or copper alloy wear-resistant plate, bronze sliding plates, sliding plates, oil-free sliding water plate.

Self-lubrication is additionally processed by embedding solid lubricants in the right places on the workpiece. Sintered alloy is an alloy in which solid lubricants are finely and evenly distributed in special alloys, and the pores are impregnated with lubricant.

The most convenient and comprehensive way to buy your self-lubricating guide bush partsSelf-lubricating Guide Bushing & Wear Plate Materials Wear plates come in a broad range of standard inch and metric sizes and are available in Manganese bronze or aluminum bronze, either with or without self-lubricating

we are exporter and suppliers of the highly competitive oilless guide elements & graphite plugged guide bushings industry in china.

The Self-lubricating Bronze Wear Plate main production materials are:

QSn10-1, QSn6.5-0.1),

Brass: H62, H65, H68, H70, H85, H90,

Tin bronze: QSn6-6-6, QSn5-5-5 CuSn10Pb1, CuSn8, CuSn4 , CuSn12,

Aluminum bronze: 60600, C64200, C60800, C61300, C61400, C61900, C62300, C62400, C63000, C63020, C63200, C65100, CuAL10Fe3, CuAL9Fe4Ni4, CuAL9Mn2, CuAL9Ni3Fe2, CuAL10Ni5Fe4, etc.

Self-lubricating Bronze Wear Plates are mainly used in the automobile industry, motorcycles, various hydraulic machinery, metallurgical machinery, forging machinery, oil field machinery, engineering machinery, mining machinery, power facilities, etc.

Self-lubricating Bronze Wear Plate features:

It is suitable for places where lubricating oil must be frequently used, places where reciprocating motion or frequent start or stop, and places where it is difficult to form an oil film.

It can be used in a self-lubricating state, no oiling device is needed, which can shorten the assembly period, reduce the pollution of lubricating oil, and beautify the social environment.

Excellent wear resistance and bite resistance.

The Self-lubricating Bronze Wear Plate solves the problem of relatively large friction between the existing slide plate and the turntable, which leads to serious wear.

It includes a plate body with a sliding surface, a chip storage groove, and a connecting hole, and the plate body One side is provided with a semicircular gap, and the sliding surface is semicircular ring shape and is arranged concentrically with the center of the semicircular gap.

The chip depositing groove is located between the sliding surface and the connecting hole and separates the sliding surface and the connecting hole on both sides of the chip depositing groove; the sliding surface has a plurality of circular holes and each of the circular holes is embedded. There are solid lubricants to reduce friction with the rotary table and ensure the normal duty cycle of the slide and rotary table.

We supply various kinds of die parts and self-lubricating guide bushings made of brass and DIN graphite. please contact us for more information, thank you.

GRAPHITE WEAR PLATE MADE-TO-ORDER FROM CHINA

SELF LUBRICATING BRONZE PLATES CUSTOMIZED SIZE

Processes: Machining, Milling, Plugging

We offer the Graphite Wear Plates -Bronze Lube Mold and Die Products area of uses metal stamping dies, molds, special machines, and heavy equipment. Oilless Wear Plate means no refueling or less refueling. The goal of our research is to ensure that the bearing can perform well in this condition and extend its service life as much as possible.

New Bearing Plates Made up of C86300 Manganese Bronze ASTM B22 Material

Graphite Plugged Wear Sliding Plate, Custom Part Manufacturing Graphite Plugged Wear Plate

We manufacture Graphite Wear Plates, Grease Groove Bronze Wear Plates No graphite, Rectangular Sizing Plates, hole patterns, or graphite patterns, according to your specifications and drawings. These are available in a variety of metric sizes & inch sizes in both manganese bronze, tin bronze and aluminum bronze, phosphor bronze.

Special manufacturing, Oilless Metal Sliding Materials. Our specialty is customized parts in bronze and brass alloy bearings.

GRAPHITE SLIDE PLATE CHARACTERISTICS

- Maintenance-free (self-lubricating Bearings)

- Suitable for heavy-load applications

- Withstands extreme temperatures

- Long life span

MATERIAL & COMPOSITION

- Support material: CuZn25Al6Mn4 Bronze with solid graphite lubricant inserts (alternative specifications are available on request)

- Sliding layer Solid lubricant graphite surface: app. 25-30%

- Other commonly used bronze alloys: CuSn6Zn6Pb3, CuSn5Zn5Pb5 Bronze Alloy Graphite Slide Plate & Wear Plate

AVAILABILITY

Wear Plates forms available in standard dimensions & Custom Design

- Rectangular Sizing Plates

- Bronze w/Graphite slide plate

- Bronze no Graphite slide plate

- Bronze w/Grease Grooves plate

GRAPHITE SLIDE PLATE RANGE OF APPLICATION

Bronze slide plates for metal stamping dies, molds, special machines, and heavy equipment. They also are used to guide and control linear motion when there are heavy forces to contend with.

SPECIAL MANUFACTURING FOR GRAPHITE SLIDE PLATE

* For higher requirements – e.g. higher temperature ranges – different materials are available in this category. Special dimensions are available on request.

ALL GRAPHITE SLIDE PLATES / SERVICES

Cast Bronze Bearings Bushings Copper Bushings Bronze Bearings Cylinder Components Plates Casting Services Graphite Bushings Hydraulic Equipment Molding Services Sleeves

| Type | WEAR PLATE SIZE | Spec. | Type | Spec. | |

| WEAR PLATE | GRAPHITE WEAR PLATE-18100 | 100~18~10 | BRONZE PLATE | GRAPHITE WEAR PLATE-4875 | 75~48~10 |

| WEAR PLATE | GRAPHITE WEAR PLATE-18125 | 125~18~10 | BRONZE PLATE | GRAPHITE WEAR PLATE-48100 | 100~48~10 |

| WEAR PLATE | GRAPHITE WEAR PLATE-18150 | 150~18~10 | BRONZE PLATE | GRAPHITE WEAR PLATE-48125 | 125~48~10 |

| WEAR PLATE | GRAPHITE WEAR PLATE-2875 | 75~28~10 | BRONZE PLATE | GRAPHITE WEAR PLATE-48150 | 150~48~10 |

| WEAR PLATE | GRAPHITE WEAR PLATE-28100 | 100~28~10 | BRONZE PLATE | GRAPHITE WEAR PLATE-50100 | 100~50~10 |

| WEAR PLATE | GRAPHITE WEAR PLATE-28125 | 125~28~10 | BRONZE PLATE | GRAPHITE WEAR PLATE-50150 | 150~50~10 |

| WEAR PLATE | GRAPHITE WEAR PLATE-28150 | 150~28~10 | BRONZE PLATE | GRAPHITE WEAR PLATE-50200 | 200~50~10 |

| WEAR PLATE | GRAPHITE WEAR PLATE-35100 | 100~35~10 | BRONZE PLATE | GRAPHITE WEAR PLATE-50250 | 250~50~10 |

| WEAR PLATE | GRAPHITE WEAR PLATE-35150 | 150~35~10 | BRONZE PLATE | GRAPHITE WEAR PLATE-50300 | 300~50~10 |

| WEAR PLATE | GRAPHITE WEAR PLATE-35200 | 200~35~10 | BRONZE PLATE | GRAPHITE WEAR PLATE-50400 | 400~50~10 |

| WEAR PLATE | GRAPHITE WEAR PLATE-35250 | 250~35~10 | BRONZE PLATE | GRAPHITE WEAR PLATE-75150 | 150~75~10 |

| WEAR PLATE | GRAPHITE WEAR PLATE-35300 | 300~35~10 | BRONZE PLATE | GRAPHITE WEAR PLATE-75200 | 200~75~10 |

| WEAR PLATE | GRAPHITE WEAR PLATE-35350 | 350~35~10 | BRONZE PLATE | GRAPHITE WEAR PLATE-75250 | 250~75~10 |

| WEAR PLATE | GRAPHITE WEAR PLATE-3875 | 75~38~10 | BRONZE PLATE | GRAPHITE WEAR PLATE-75300 | 300~75~10 |

| WEAR PLATE | GRAPHITE WEAR PLATE-38100 | 100~38~10 | BRONZE PLATE | GRAPHITE WEAR PLATE-75400 | 400~75~10 |

| WEAR PLATE | GRAPHITE WEAR PLATE-38125 | 125~38~10 | BRONZE PLATE | GRAPHITE WEAR PLATE-75500 | 500~75~10 |

JSP Self-Lubricating Graphite Wear Plate: The Future of Industrial Lubrication

Industrial machinery and equipment are subjected to intense wear and tear due to continuous use, which can lead to performance degradation and ultimately, machinery failure. Wear plates are widely used to minimize this problem by providing a protective barrier between moving parts. However, traditional wear plates require constant lubrication to ensure smooth operation, and the lubrication can often be a hassle, leading to downtime and increased maintenance costs.

The JSP Self-Lubricating Graphite Wear Plate is a game-changer in the world of industrial lubrication. It provides the perfect solution to the constant need for lubrication by embedding graphite into the plate. This unique design provides a self-lubricating mechanism that eliminates the need for constant manual lubrication, thus minimizing maintenance downtime and costs.

The self-lubricating properties of the JSP wear plate are due to the unique combination of high-quality graphite and high-density polyethylene (HDPE) resin. The graphite acts as a solid lubricant, reducing friction and wear on the moving parts, while the HDPE provides a strong and durable base for the plate.

One of the key benefits of the JSP self-lubricating graphite wear plate is its long-lasting and durable performance. Traditional lubrication methods can wear off quickly, leading to increased maintenance costs and reduced machine performance. However, the graphite embedded in the JSP wear plate is long-lasting and provides consistent lubrication, ensuring a prolonged lifespan of the machinery.

In addition to its self-lubricating properties, the JSP wear plate is also highly resistant to corrosion, chemicals, and high temperatures. This makes it an ideal choice for industrial applications where machinery is subjected to harsh environments and extreme temperatures.

The JSP wear plate is also easy to install, making it an attractive option for companies looking to reduce downtime and maintenance costs. It can be cut to any size or shape and can be installed on any type of machinery or equipment, making it a versatile solution for many industrial applications.

Overall, the JSP Self-Lubricating Graphite Wear Plate is a revolutionary product that offers numerous benefits to industrial machinery and equipment. Its self-lubricating properties, durability, resistance to corrosion and high temperatures, and ease of installation make it an attractive option for companies looking to reduce maintenance costs and increase machinery performance. As the demand for more efficient and cost-effective industrial lubrication solutions continues to grow, the JSP wear plate is poised to be at the forefront of the industry.

UNIT:mm

| CODE | W | L | a | b | C | d | e | bolt holes size | holes |

| JSP-1875 | 18 | 75 | 15 | 45 | — | — | — | M6 | 2 |

| JSP-18100 | “ | 100 | 25 | 50 | “ | “ | ,, | “ | “ |

| JSP-18125 | “ | 125 | “ | 75 | “ | “ | n | “ | “ |

| JSP-18150 | “ | 150 | “ | 100 | “ | “ | “ | “ | |

| JSP-2875 | 28 | 75 | 15 | 45 | “ | “ | “ | “ | |

| JSP-28100 | “ | 100 | 25 | 50 | “ | “ | “ | “ | |

| JSP-28125 | “ | 125 | “ | 75 | “ | “ | “ | “ | |

| JSP-28150 | “ | 150 | “ | 100 | “ | “ | n | “ | “ |

| JSP-351OO | 35 | 100 | 20 | 60 | “ | “ | M8 | “ | |

| JSP-35150 | “ | 150 | “ | 55 | 55 | “ | “ | 3 | |

| JSP-35200 | “ | 200 | “ | 55 | 50 | 55 | “ | 4 | |

| JSP-35250 | “ | 250 | “ | 70 | 70 | 70 | n | “ | “ |

| JSP-353OO | “ | 300 | “ | 65 | 65 | 65 | 65 | “ | 5 |

| JSP-35350 | “ | 350 | “ | 80 | 75 | 75 | 80 | “ | “ |

| JSP-3875 | 38 | 75 | 15 | 45 | — | — | — | M6 | 2 |

| JSP-38100 | “ | 100 | 25 | 50 | “ | “ | “ | “ | “ |

| JSP-38125 | “ | 125 | “ | 75 | “ | “ | “ | “ | “ |

| JSP-38150 | “ | 150 | “ | 100 | “ | “ | “ | “ | “ |

| JSP-4875 | 48 | 75 | 15 | 4S | “ | “ | “ | “ | “ |

| 2SP-48100 | “ | 100 | 25 | 50 | “ | “ | “ | “ | “ |

| JSP-48125 | “ | 125 | “ | 75 | “ | “ | “ | “ | “ |

| JSP-48150 | “ | 150 | “ | 100 | “ | “ | “ | “ | “ |

| JSP-50100 | 50 | 100 | 20 | 60 | — | — | — | M8 | “ |

| JSP-50150 | “ | 150 | “ | 55 | 55 | “ | “ | “ | 3 |

| JSP-50200 | “ | 200 | “ | n | 50 | 55 | “ | “ | 4 |

| JSP-50250 | “ | 250 | “ | 70 | 70 | 70 | “ | “ | “ |

| JSP-50300 | “ | 300 | “ | 65 | 65 | 65 | 65 | “ | 5 |

| JSP-50400 | “ | 400 | “ | 90 | 90 | 90 | 90 | “ | “ |

| JSP-75150 | 75 | 150 | “ | 110 | — | — | — | “ | 4 |

| JSP-75200 | “ | 200 | “ | 80 | 80 | “ | “ | “ | 6 |

| JSP-75250 | “ | 250 | “ | 105 | 105 | “ | “ | “ | “ |

| JSP-75300 | “ | 300 | “ | 85 | 90 | 85 | “ | “ | 8 |

| JSP-75400 | “ | 400 | “ | 120 | 120 | 120 | “ | “ | “ |

| JSP-755OO | “ | 500 | “ | 115 | 115 | 115 | 115 | “ | 10 |

| How to order: Part No.W L |

| made to order order:JSP 18 75 |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

JSP OILLESS WEAR PLATE STANDARD METRIC SIZE

|

JSL L Type Standard Self-Lubricating Wear Plate: The Solution to High-Performance Wear Resistance

Wear plates are used to reduce friction and wear in a variety of industrial applications. The use of self-lubricating wear plates has gained popularity in recent years as they offer superior performance compared to traditional wear plates. Among the self-lubricating wear plates, the JSL L Type Standard Self-Lubricating Wear Plate stands out for its excellent wear resistance, high strength, and long lifespan.

The JSL L Type Standard Self-Lubricating Wear Plate is made from high-strength brass, tin bronze, steel and copper bimetal, cast iron or bearing steel as the base material. The surface of the wear plate is inlaid with graphite (SL1) or PTFE with molybdenum disulfide (SL4) as the main component of solid lubricant. This solid lubricant reduces friction, improves wear resistance and extends the lifespan of the wear plate.

One of the key advantages of JSL L Type Standard Self-Lubricating Wear Plate is its exceptional wear resistance. The solid lubricant inlaid on the surface of the plate reduces the friction between the wear plate and the opposing surface, which reduces wear and tear. This property makes it ideal for applications where wear and tear are a concern, such as heavy machinery, mining equipment, and hydraulic systems.

In addition to its wear resistance, JSL L Type Standard Self-Lubricating Wear Plate also has high strength. The use of high-strength materials as the base material ensures that the wear plate can withstand high loads and stresses without cracking or breaking. This property makes it ideal for applications where the wear plate is subjected to heavy loads or impacts, such as excavators, bulldozers, and cranes.

The long lifespan of JSL L Type Standard Self-Lubricating Wear Plate is another significant advantage. The solid lubricant inlaid on the surface of the plate reduces wear and tear, which extends the lifespan of the wear plate. This property reduces maintenance costs and downtime, making it an attractive option for companies that rely on their equipment’s performance.

JSL L Type Standard Self-Lubricating Wear Plate is available in two types of solid lubricants: graphite (SL1) and PTFE with molybdenum disulfide (SL4). The SL1 type is suitable for applications where water or seawater is used as a lubricant. The SL4 type is suitable for applications where high temperature and pressure are present, such as hydraulic systems.

In conclusion, JSL L Type Standard Self-Lubricating Wear Plate offers excellent wear resistance, high strength, and a long lifespan, making it an ideal choice for a wide range of industrial applications. The use of solid lubricants reduces friction, improves wear resistance, and extends the lifespan of the wear plate. With its exceptional properties, JSL L Type Standard Self-Lubricating Wear Plate is a reliable and cost-effective solution for companies looking to improve the performance and lifespan of their equipment.

| CODE | Type | W | L | a | b | c | d | bolt holes | |

| SIZE | QTY | ||||||||

| JSL-26100 | C | 26 | 100 | 60 | — | — | — | M8 | 2 |

| JSL26150 | “ | “ | 150 | 55 | 55 | — | — | “ | 3 |

| JSL-26200 | “ | “ | 200 | “ | 50 | 55 | — | “ | 4 |

| JSL-32100 | B | 32 | 100 | 60 | — | — | — | M10 | 2 |

| JSL-32150 | “ | “ | 150 | 55 | 55 | — | — | “ | 3 |

| JSL-32200 | “ | “ | 200 | “ | 50 | 55 | — | “ | 4 |

| JSL-32250 | “ | “ | 250 | 70 | 70 | 70 | — | “ | “ |

| JSL-50200 | A | 50 | 200 | 55 | 50 | 55 | — | “ | “ |

| JSL-50250 | “ | 250 | 70 | 70 | 70 | — | “ | “ | |

| JSL-50300 | “ | “ | 300 | 65 | 65 | 65 | 65 | “ | 5 |

| JSL-50350 | “ | “ | 350 | 80 | 75 | 75 | 80 | “ | “ |

The lifespan and wear of a C86300 bronze oilless slide plate depend on several factors, including the operating conditions, load, speed, alignment, and maintenance. In general, C86300 manganese bronze is known for its excellent wear resistance, high strength, and good load-carrying capacity, making it a suitable material for oilless slide plates in various applications.

C86300 bronze oilless slide plate can offer a relatively long service life under normal operating conditions. However, it is essential to consider several factors that may impact the lifespan and wear of the slide plate:

- Alignment and installation: Proper alignment and installation of the slide plate are crucial to ensure even load distribution and minimize uneven wear or premature failure.

- Operating environment: Exposure to corrosive or abrasive environments may accelerate wear and reduce the slide plate’s lifespan. In such cases, regular cleaning and protective measures may help prolong the service life.

- Load and speed: Operating the slide plate at or near its maximum load capacity and speed may result in increased wear and reduced service life. Ensuring that the slide plate operates within its specified load and speed limits can help extend its lifespan.

- Maintenance and lubrication: Although C86300 bronze is designed for oilless applications, occasional lubrication or maintenance may be beneficial, especially in harsh environments or during the initial run-in period. Regular inspection and maintenance can help identify potential issues and prevent premature wear or failure.

- Material quality: The quality of the C86300 bronze material itself can impact the slide plate’s wear resistance and lifespan. Ensuring that the material meets industry standards and specifications is crucial for optimal performance and durability.

Considering these factors, it is challenging to provide an exact lifespan or wear estimate for a C86300 bronze oilless slide plate under the specified conditions. However, with proper installation, alignment, and maintenance, such a slide plate can offer a long service life while providing reliable and low-friction performance in various applications. Regular inspection and monitoring of the slide plate’s wear and condition can help optimize its performance and longevity.

Design is flexible, simple, convenient, use widely.

Custom Design & Reliable Graphite Slide Plate Solutions, low cost! ASTM B505 C86300 Sliding Plate, Bronze Graphite. Aluminum bronze plate. Requesting a quote is just a click away! In the ever-evolving world of industry and machinery, having a partner that understands precision, quality, and reliability is invaluable. Let us be that partner for you. Dive into the world of custom graphite solutions with us, and experience the difference of true craftsmanship.

Customized Graphite Product Manufacturing: Precision, Quality, and Expertise

Precision Engineering: Our advanced machinery and skilled workforce ensure that every product is crafted to the minutest detail, ensuring a perfect fit for your applications. If you have any further questions on our grades or how we can develop a customized wear plate product for you! oil free can be used. Excellent drug resistance & corrosion resistance. Copper alloy, Slide Plate, continuous, centrifugal, sand and static cast.

Bronze Wear Plates & Graphite Plugs

Exporter and designer of graphite slide plate, Manganese Bronze Slide Plate C86300, SAE 430B, self-lubricating slider, graphite plugged wear plate, flanged brass bushings etc. long replacement cycle and convenient, good performance. Fill out our contact form with your requirements, or for a more personalized experience, call us directly. Our team of experts is on standby, ready to assist you with any queries, ensuring you get a product that aligns perfectly with your needs.

We Offer A Full Line Of Plug Graphite Bushing & Graphite Impregnated Plates.

More Information On Our Graphite Plugged Parts Can Be Found Here! Graphite Plugged Bronze C86300 Manganese Bronze SAE 430B Wear Sliding Plates, Bronze Alloys. Anti-corrosion and flushable slide plate, high rigidity and high precision, easy assembly, low price and fast delivery, quality assurance. The slide plate manufacturer has many years of experience in manufacturing, and we can get the technical solution of self-lubricating bearing.

Oilless Bearing & Wear Plate Prototypes

Type Of Customized Self-Lubricating Bearings Graphite Bushing

Graphite slide plates are indispensable in many industries, offering a reliable solution for managing movements and stresses. Their combination of self-lubrication, durability, and versatility makes them a preferred choice for engineers and industry professionals worldwide. When selecting graphite slide plates, it’s essential to consider the load they will bear, the expected movements, and the environmental conditions they will be exposed to. This ensures that the chosen slide plate is optimal for the application and will function efficiently over its intended lifespan.