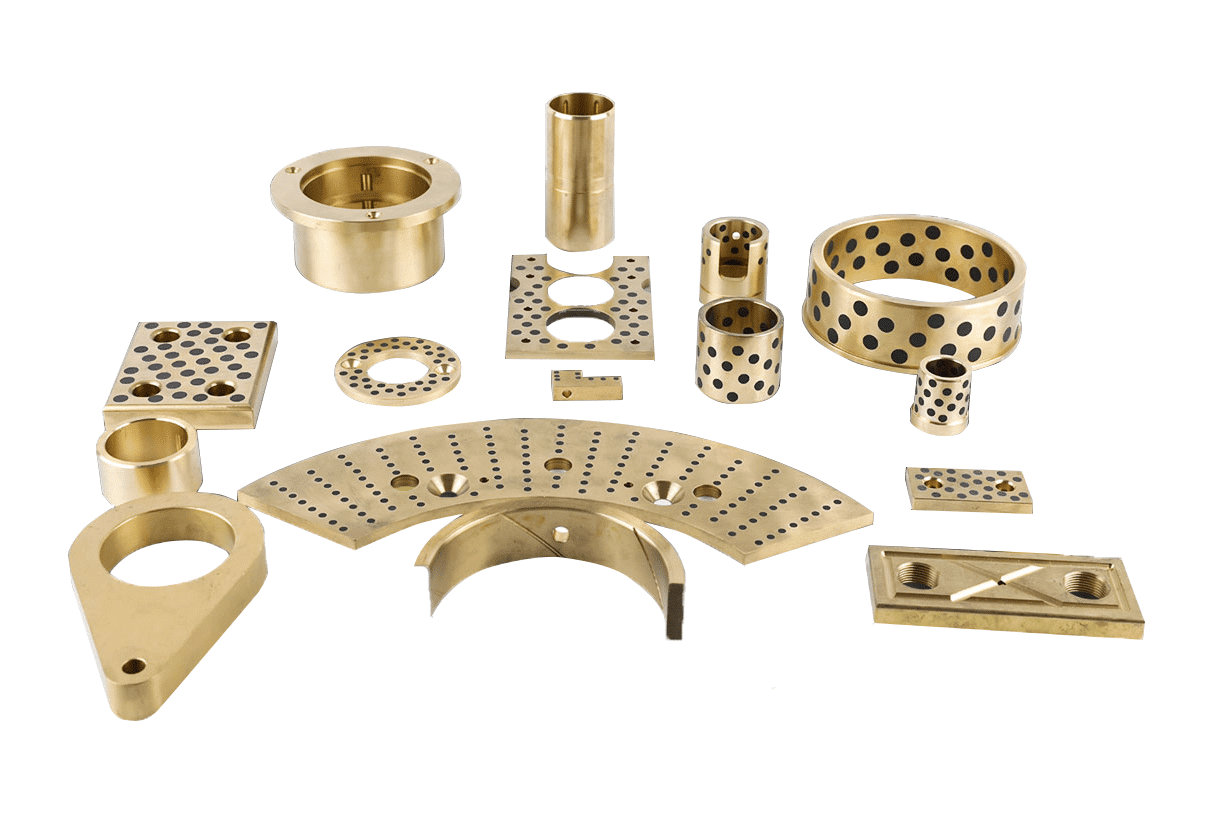

Slide Oilless wear Slide Bearing plates Supplier

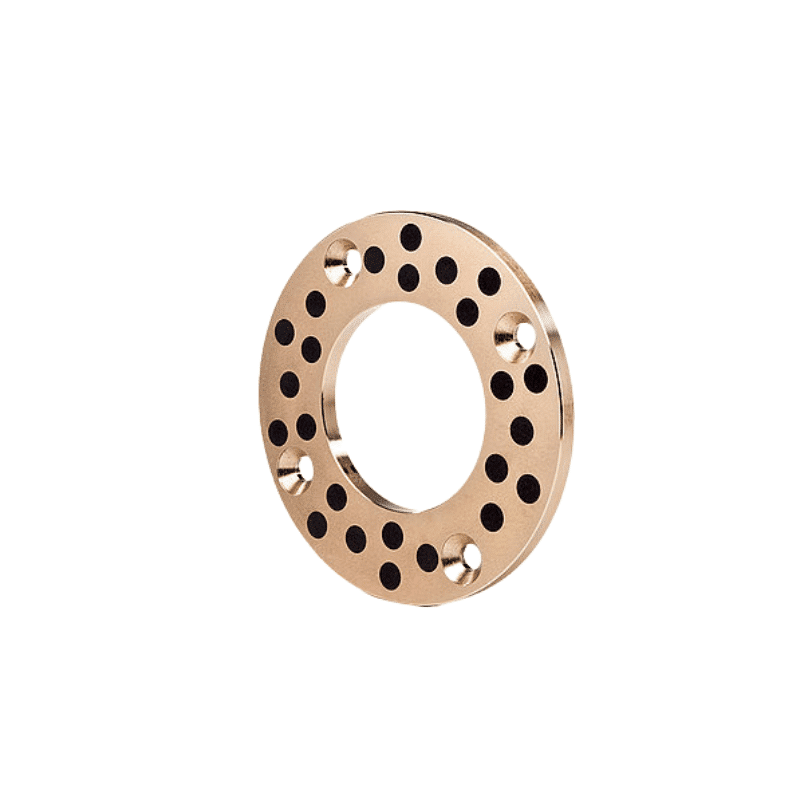

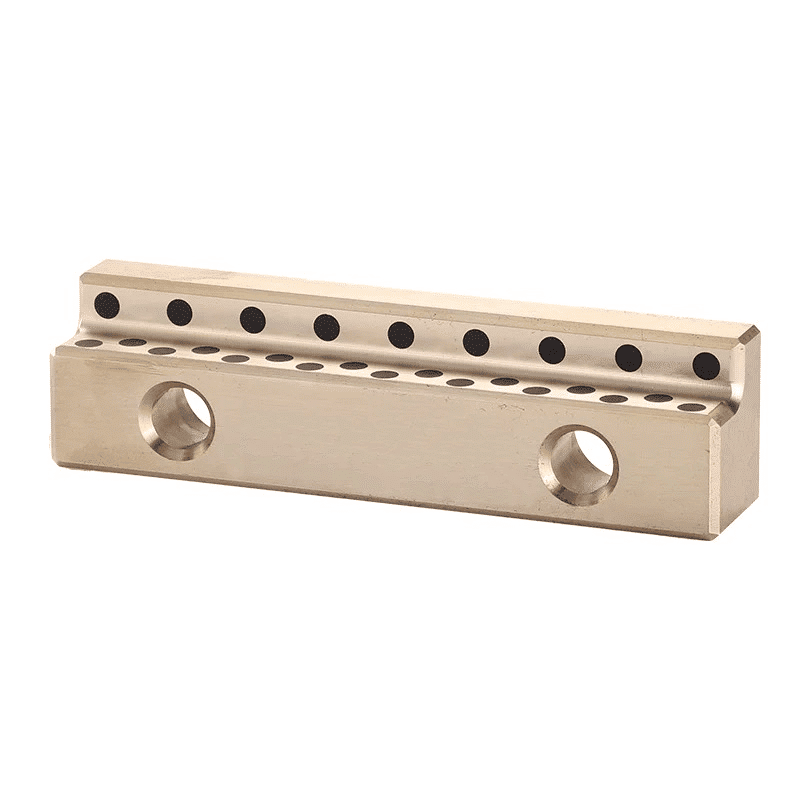

Wear plate pipe support graphite wear plates come in a variety of sizes. They come complete with self-lubricating graphite and are made of aluminum bronze. The slide bearing plates are manufactured from bronze with graphite plugs covering 25% of the wear surface. PTFE Slide Bearings For Oil & Gas Industries.

80%

Sales Growth

90+

Projects Delivered

slide Bearing Plate

Plugged graphite Bronze Plate

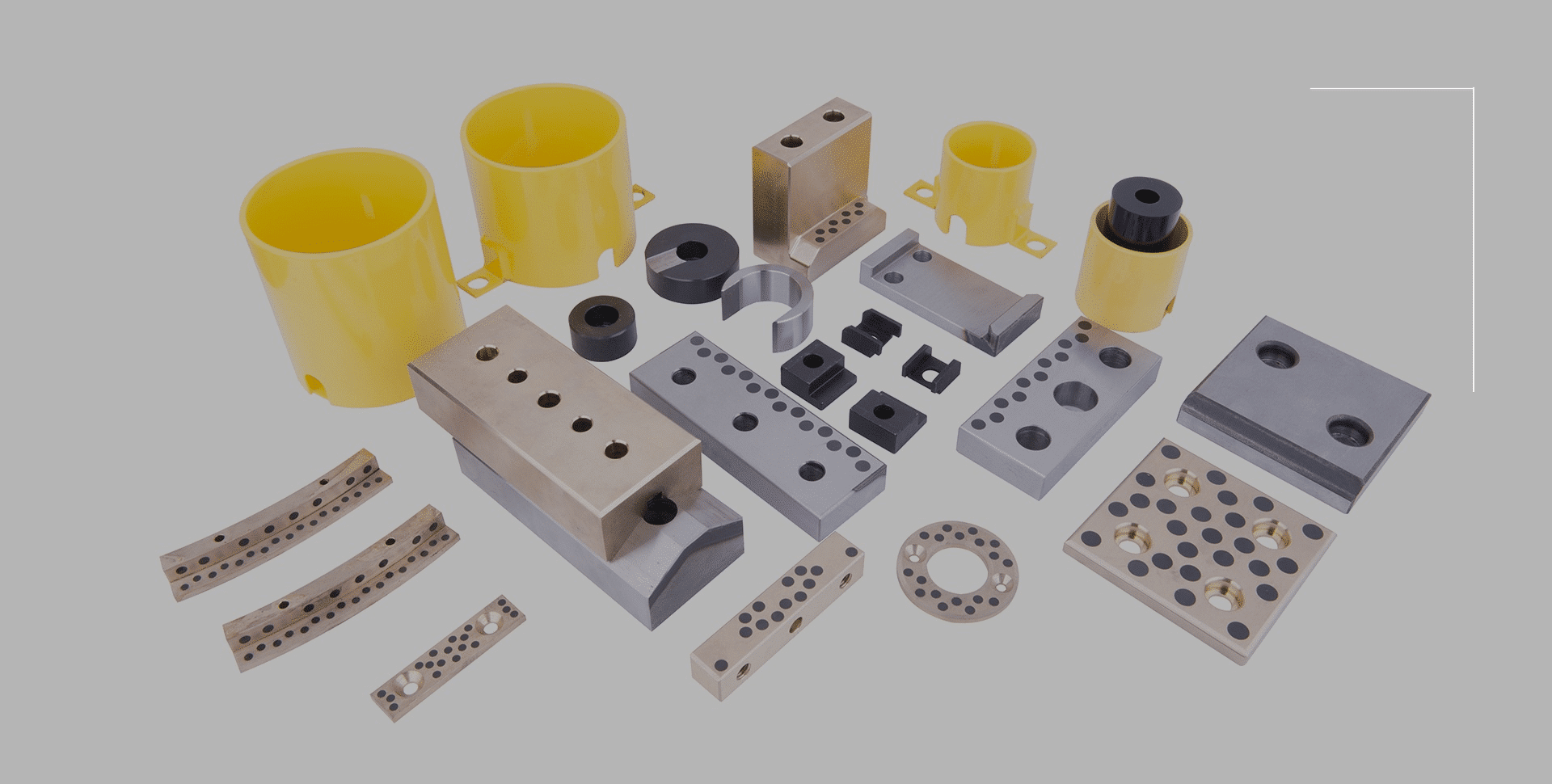

Bronze Graphite Slide, Bearings & Pipe Supports, Heavy plate for Offshore Oil & Gas, Self-Lubricating Bearing JSP Plate.

professional

Slide bearing Plate Supplier

Slide Bearings, Pipe Supports. Slide Bearing & Sliding Plates Configurations, Bronze Slide Plates for Pipeline Supports

sliding plate Bearing

Focus piping technology

Self Lubrication Sliding Plate, Bronze Slide Bearing Plates for Pipeline Support Systems, Oil and Gas Applications and Design Features

Oil-Free Slide Plates piping technology

Supplier

Offshore Bridge, Sliding Bearings and Plate, Slide Plates – Oil Free sliding brass, cast bronze, and other …

Bronze with Graphite Plugs For piping technology

Sliding wear plates are linear bearings that may be part of expansion joints in bridges, high temperature horizontal piping in water tube boilers and other mechanical or structural engineering applications. In each case, one plate is fixed and the other slides over it in the event of expansion or contraction.

about the company

slide bearing plates- graphite Plate For piping technology

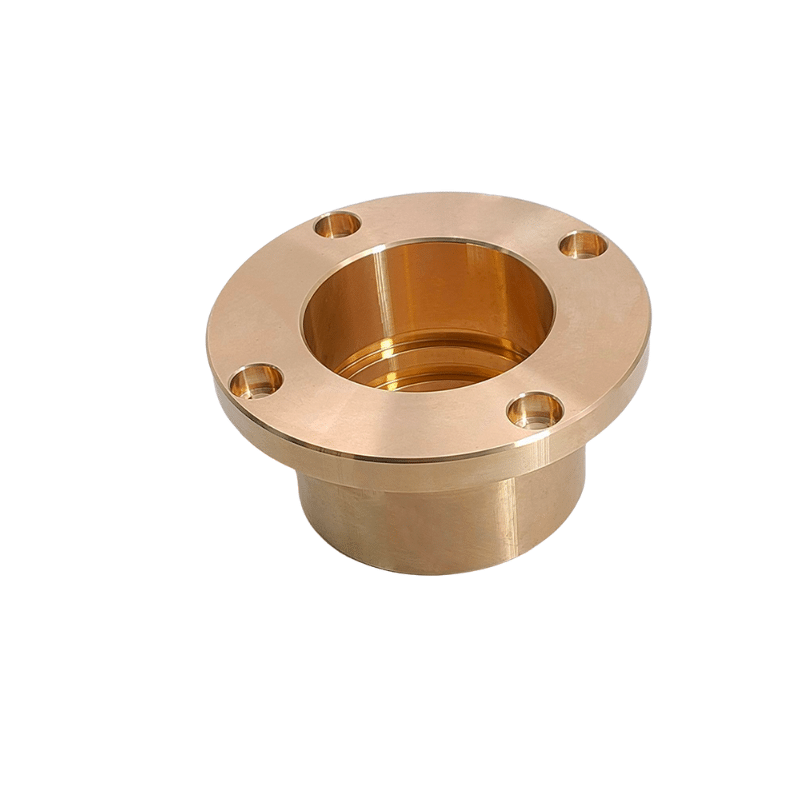

Graphite impregnated bronze slide bearings plate combined with a carbon steel backing plate, to be field welded. Oil Free Slide Plates for industrial applications. Oil Free Slide Bearing Bronze Graphite Plates for industrial applications. we offers free CAD downloads, short lead times, competitive pricing, and small minimum order quantity.

Product Quality Index

Energy Generation

Wear Sliding Plates Graphite Self-lubricating Bearing for piping technology

We get things rolling: Maintenance-free, self-lubricating sliding bearings from China have been proving themselves in innumerable industrial applications. If your company works in a steel, pipeline, or aluminum plant, a chemical company, the mining industry or the military, then you need to wear plates! Wear plates are used to guide and control linear motion when there is gravity to contend with. Although they were originally developed for metal stamping dies, wear plates have many other uses in molds, special machines, and heavy equipment. We produce wear plates that conform to all industry standards (VDI, JIS, NAAMS, SMC). Our wear plates are available in a wide range of standard inch and metric sizes, in steel or aluminum bronze, with or without self-lubricating graphite. If a standard wear plate won’t do, we can economically custom configure it for a special size, hole pattern or graphite pattern. Also, don’t forget to check out our wear bar section. Wear bronze strips are a similar product, but available in a wider range of sizes.

Need a Self-lubricating Bearing or Bronze wear plates Graphite plates? Request a quote today, or contact us for more information!

Everything from a single source, High quality sliding bearings

Beautifully crafted leather products.

Our products can be found in large machinery, the construction and automotive industries, wind turbines and hydroelectric power plants as well as in general mechanical engineering. A team of experienced experts is at your service worldwide to develop, install and take care of your plain bearing solutions. From design and installation to inspection, your self-lubricating thrust bearing and washer service partner. Our team of experts acts globally to know your application, understand your requirements and provide you with individual solutions for your slide plate bearings. Types: Plate, Cylindrical Bearing, Flanged Bearing, Spherical Bearing, Other shapes.

If any problems arise in the process, we are always there for you. Short distances, fast solutions! Our mission is to find solutions for your personal projects! Low friction. Great performance.

wear Sliding Bronze plates Manufacturer, Graphite Plates

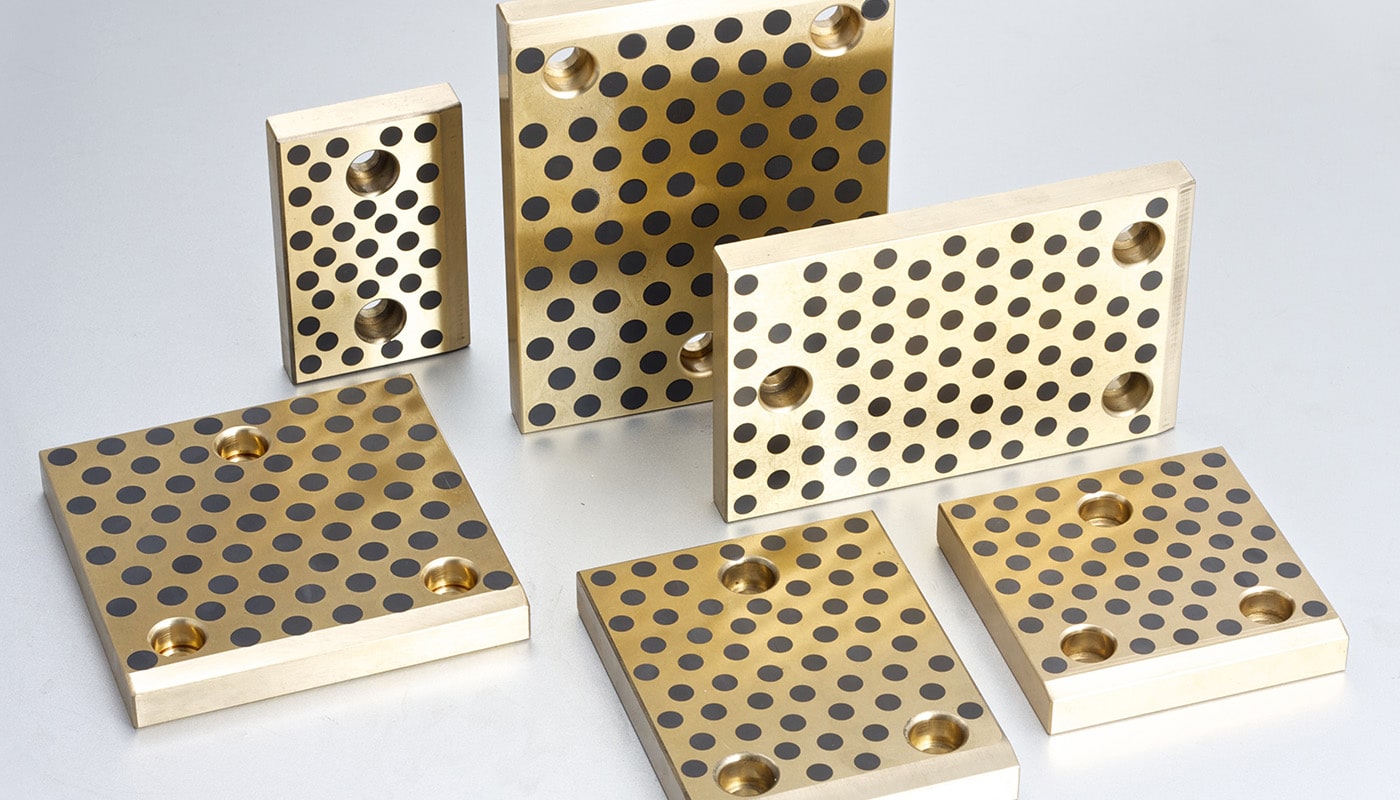

Wear plates are used to guide and control linear motion when there are heavy forces to contend with. When supplied with graphite plugs, the plugs cover 20-30% of the wear surface and the plates are self-lubricating. Wear Plate Manufacturer – Bronze Sliding Plates Supplier. We offer Slide Graphite Bearings for the pipeline, process plants, chemical plants, and engineering. High-Temperature oilless bearings! The range of sliding plates and bearings are based on tried and tested slide bearing manufacturing procedures, which ensure low coefficient of friction, and reliability in varying environments throughout the world.

Now Offering Manganese Bronze Plate, C86300 Manganese Bronze Sliding Graphite Plate provide tensile and yield of 110,000 psi and 62,000 psi respectively. The unit meets ASTM B505 and ASTM B22 standards. The product features an elongation of 14% and comes with a uniform and fine grain structure. The plate is suitable for bridges and metal-forming equipment applications. Technical Data:

- CDA 86300, CuZn25A16Fe3Mn3

- ASTM B505, ASTM B22

taxation planning

Eiusmod tempor incididunt ipsum ut labore dolore magna aliqua. Ut enim minim veniam duisy ipsum sed quis.

C863 Slide Plates Supplier For piping technology

Manufacturer/supplier of bronze alloys and mechanical components, has added C86300 manganese bronze sheet to its inventory of copper-based alloys. Slide Plates – Plastic Mold Components components for mold process, Fast delivery small minimum order. C86300 manganese bronze plate material meets SAE 430B standards. This sheet is continuously cast to ensure that the bronze bar stock has the most uniform and fine-grained structure, free of impurities. Manganese bronze sheet is used in a number of components in a variety of industries.” From bearing plates for bridges to wear resistant liners for metal forming equipment, Manganese Bronze Graphite Slider Designers and Suppliers”

“Adding this size/shape combination to our inventory not only allows us to offer our machined parts in a shorter time frame, but also allows us to offer our metal service center customer base materials that used to require extensive machining and lead times of four weeks or more.” In addition to offering cast bronze sliding plate/thrust washer products, we also design and customize sliders to better serve our customer base. We provide our customers with the exact self-lubricating slider material they need for their projects without the need to order excess material due to standard size limitations”.

bronze wear plate, Slide Plates Thickness, Slide Plate Standard Components

By using the leaded, corrosion-resistant bronze CuSn7ZnPb7, self-lubricating graphite slide plate bearing offers a high-performance solution in combination with the C86300 self-lubricating properties of the graphite solid lubricants. Choose from our selection of bronze wear slide plates and strips in a wide range of material and sizes. In stock and ready to ship. Standard-sized slide plate, self-lubricating bronze wear strips, featuring low coefficient of friction, are resistant to wear, …Wear Strips & Wear Plates Supplier and Design, CAD drawings….

Low Friction Slide Plates -The slide plates are available in 10, 20, 30, 45 and 60mm thicknesses and in widths of 100, 125 and 160mm. The self-lubricating slide plates are available in bronze and self-lubricating versions and fully meet the standard. For ease of identification, all plates are marked with the part number and slide plate code. However when used for slide plate heavy structures or as a bridge-bearing assembly with a different assembly configuration may be advantageous to incorporate a lubrication system to assist with the reduction of friction.

Your Safe & Reliable Oil-free Slide Plates Supplier, Delivers punctually and offers fair prices.

Use Slide Graphite Bearings For High Performance And Low Maintenance. Non-galling. Run dry & keeps running. Hi Temp Bearing Solution. Increased reliability. Reduced costs & downtime. Services: Custom Design, Engineering Support, Short Lead Times. Maintenance-free, self-lubricating Bearings!

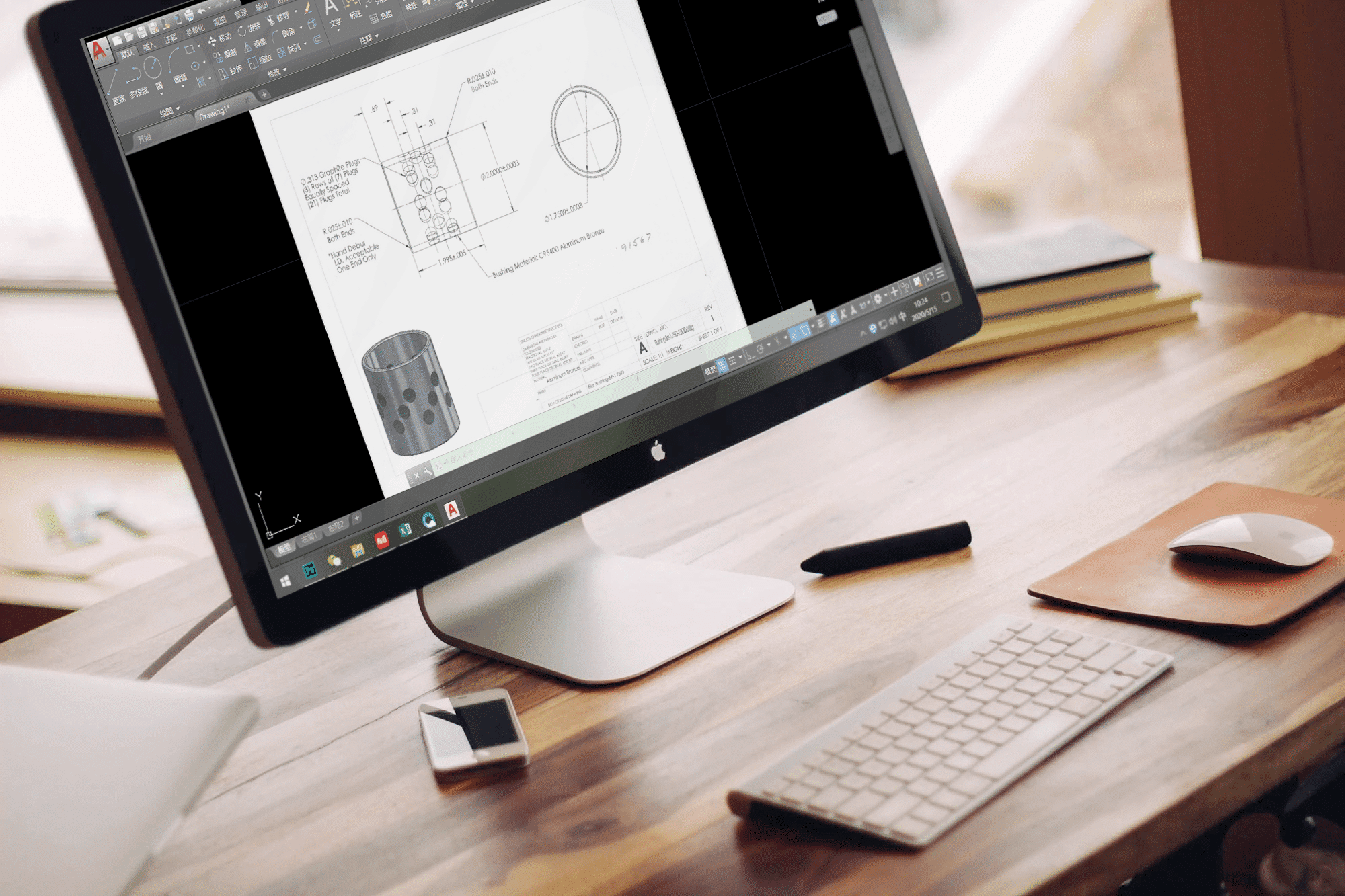

Ordering your sliding bearing plates: Before we can start making your sliding bearing plate, we only need a few pieces of information from you. The slide plate size, shape and material required for the low-friction surface, based on the highest temperature and load combination that the surface will experience. The slide bearings size, shape and material of the metal sliding plate for the low friction surface. Sliding bearing plates If you have a unique problem, we will be happy to custom design a practical solution to your problem.

Graphite Bronze Slide Plate & Bronze Bushings – In High Temps, Reduced costs & downtime, Increased productivity. Need Assistance? Call Or Email Us. To Get Your Queries Answered. A metallic sliding plate has been used widely. The sliding plate series are self-lubricating Wear plates composed of high strength brass alloy bases made with advanced casting technology and embedded solid lubricants. They may be combined with various types of solid lubricants according to the conditions of use.

CuZn25A16Fe3Mn3 Bronze slide plate

oil drilling platform Slide Plate, Proprietary Material, sliding bearings move the world

Supply a large number of JSP sliders for jack-up oil rigs. Supply of self-lubricating maintenance-free bushings for oil and gas transmission systems. JSP inlay solid lubricated slide bearing graphite plate is a high performance solid lubricant product with graphite or molybdenum disulfide inlay on a high force brass substrate. Self-lubricating slide bearings for pipe-laying equipment and stinger connections. Materials for long time use in marine and submerged applications! We develop custom solutions for your individual applications and industries with innovative high-tech slide bearing products and technical expertise. It has high bearing capacity, impact resistance, high temperature resistance, self-lubricating ability, etc. It is especially suitable for …The functions of lubrication. The main function of the lubrication of rolling bearings is to prevent.

Product Quality Index

Energy Generation

Graphite Self-lubricating Bearings & Slide Plate, Select, configure, order.

With an extensive manufacturing program for self-lubricating bearings and slides, we are a popular partner in the machine tool industry, pipeline construction, instrumentation, power generation, and many other specialized markets. Whether An Individual Slide Plate Or A Complete Graphite Plate – We Machine The Necessary Wear Plates Entirely According To Your Specifications.

Construction Technology Equipment

Self-lubricating slide plate are available for piping systems. As a supplier of slider bearings, we work with OEMs in the building technology sector.

SPECIAL MACHINING- MACHINE AND FABRICATE REPLACEMENT SLIDE BRONZE PARTS

Manufacturing Sliding Bearing Standards

The standard complies with the tolerances specified in the relevant slide plate information and machining standards. in special machining. . Whether complete machining according to drawing or partial machining based on your requirements – you can rely on our know-how and high quality when it comes to special machining.

Benefit From Our Technical Service

Our top priority is providing you with an optimal offer for your slide plate as fast as possible. our integrated CAD system enables even faster processing and saves you having to submit technical drawings. We are able to process all common CAD data. Compact Oil-Free Slide Plates – Copper Alloy.

We Offer Customized Slide Plate Solutions

Base Plates For Gib Assemblies, We are happy to point out any potential savings to you when preparing the offer. You can rely on complete project support from the offer to after-sales service. We manufacture slide plate for deep holes, lateral threads and markings in short order.

STANDARD BRONZE PLATE & SLIDE BEARING PARTS PROJECTS!

Various Standard Wear Plates & Sliding bearings parts are available. We Are Known On The Market For Special Machining In Premium Quality. Function: Slide plate• Material: Copper alloy• Thickness (mm): Oil Groove: Oil-free Plate, Volume Discount is available!

Your Safe & Reliable Oil-free Slide Plates Supplier, Delivers punctually and offers fair prices.

Sliding Plate from China. We offer CAD design, short lead times, competitive pricing, and small minimum order … Bronze Self-Lubricating wear plate, bronze strips and bronze gibs are made from bronze plugged graphite. The oilless bearing parts can be used in applications up to 450° F (232°C). Bronze is a strong material that resists wear, abrasion & deformation under high compressive loads. With a strong supply capacity in China, we are able to offer an extensive range oil-free slide plates products to every industry, which include bronze bushing, self-lubricating bearings, plugged bronze graphite bushing, and more. Compared with normal plain bearings, Graphite Self-lubricating bearings are superior in wear resistance, seizure resistance and friction properties, and realize performance enhancement and maintenance-free.

Our team of experts work with you as equals to get to know your application, understand it, and guide it to success. The complexity of your project doesn’t matter. Benefit from our expertise and let us discuss your next challenge with confidence.

Precision Sliding Wear Plate.

Manufacturer and supplier of bronze based products. Supplier bronze bushings, bush bearings, and other industrial components. Oil Free Slide Plate (metric size and inch size). Full metal service center supplying bronze bearing, brass bushes, and sliding plate stock to manufacturers worldwide. With an expertise in copper alloy based product custom self-lubricated bronze bearing services customers in a wide variety of industries. Oil Free Wear Graphite Plate for universal use in many dry application such as die/mold, machinery, automation, construction, automobile. Shop online for all your Oil-Free Slide Plates and Oil-free Slide Plates needs. We offers free CAD download, short lead times, competitive pricing, …

Bronze Graphite Slide Plates

Oil-Free Slide Bearing Plates Factory Price

We manufacturing slide bearing plate tailored to your needs.

Slide Plates Bearing Made up of C86300 Manganese Bronze Material, Bronze Slide Plate for Bridge Expansion Bearings

Wear sliding plates: If your company works in a steel, pipeline, or aluminum plant, a chemical company, mining or the military sector, then you need to wear plates Wear plates are used to guide and control linear motion when there is gravity to contend with. Although they were originally developed for metal stamping dies, wear plates have many other uses in molds, special machines, and heavy equipment. Wear plates are produced to meet all industrial standards (VDI, JIS, NAAMS, SMC).

Our wear plates are available in a wide range of standard inch and metric sizes, in steel or aluminum bronze, with or without a self-lubricating graphite plate.

If a standard wear plate won’t do, we can economically custom configure it for a special size, hole pattern or graphite pattern. Also, don’t forget to check out our wear bar section. Wear strips are a similar product, but available in a wider range of sizes. Need a wear sliding plate? Request a quote today, or contact us for more information!

Can Economically Make Custom Slide Plate In Custom Size? Made in China. To learn more about manganese bronze slide-bearing plates, Graphite Plugged Products, Contact us today.

Manganese bronze wear plates with graphite plugs are produced. These wear plates will be used as slide-bearing plates and are an integral part of the bridge expansion bearings. Material. C86300 Manganese Bronze ASTM B22, Process. Machining, milling, and plugging of holes for Bridge Construction

Bridge slide bearings are structural devices installed between the substructure and superstructure of a bridge to transfer the applied load. Bridge slide plates also provide space for relative movement between these structures. Movements can be rotational and translational, as well as in horizontal and lateral directions. This slide bearing plate allows controlled movement and reduces stresses in motion. C86300 manganese bronze conforming to ASTM B22 specifications is used for its ability to withstand heavy loads and very slow movements. c863 bronze has a very high tensile strength of 110ksi and a high yield strength of 62ksi. This alloy also exhibits good corrosion resistance.

The bronze slide-bearing plates are drilled and plugged with solid lubricant graphite plugs. These plugs cover 30% of the total surface area and are arranged geometrically with overlapping rows in the direction of motion. These slide plates have four countersunk mounting holes and a center hole for mounting and handling of the entire bearing assembly.

The graphite plugs in these slide graphite plates allow the slide plate bearing to be maintenance-free. No supplemental lubrication is required for the life of the slide-bearing plate. This is an important factor when dealing with structures such as bridges. Slide Bearing plate maintenance would be very expensive and disruptive. Graphite plug slide bronze plates are the perfect solution to this unique problem. To learn more about the bronze wear plate product line, Wear Plates. To request a quote for a custom bronze slide bearing plate, inquire Now. Submit your quote with our online ordering form.

Bronze Slide Plates Features.

Whenever a self-lubricating bearing slide plate design is required, we provide the best technical solution.

- Slide bearing plate bronze graphite flexible, simple and convenient design, wide range of application.

- Slide wear plate No oil can be used.

- Slide bearing plate bronze graphite Low cost of use.

- Sliding Plates Excellent performance under high load and low speed conditions.

- Superior wear resistance in places where oil film formation is difficult, such as reciprocating motion, oscillating motion, and frequent starting and stopping.

- Graphite embedded plate superior chemical resistance and corrosion resistance.

- The Wear pad self lube Graphite cost is more competitive, compared with similar products, the working life is longer, less maintenance is required, the replacement cycle is long and convenient, and the performance is good.

- Graphite wear plate even under severe working conditions, they can show excellent self-lubricating durability.

Graphite Slider Support Plates for pipelines, manufacturer and supplier of slide plate bearing products

Slide Plate made up of C86300 manganese bronze and solid lubricant graphite plugs suitable for environments with temperatures up to 500 °C. These slide plate can be easily installed due to the raised graphite plugs and the rounded corners. With the coefficient of friction around 0.12 to 0.15, the slide plates can be used for numerous pipeline support systems in applications ranging from oil and gas to industrial system.

When structures get hot, they expand. This expansion must be taken into account in the design of the structure. Just as bridges and buildings expand and contract due to changes in ambient temperature, pipelines expand and contract due to changes in the temperature of the fluid they carry and changes in the weather outside the pipeline.

Pipelines expand and contract by amounts determined by the shape and coefficient of thermal expansion of the materials used to construct them. If these pipes are not allowed to expand and contract freely, severe stresses can be induced, which can lead to failure or overload. Graphite Slide Support Plates: A very effective way to accommodate pipe expansion is to allow one item to move relative to another. This can be accomplished by using low-friction sliding plate that separate the expanding item from the support structure. The core of these plain bearings is a self-lubricating bronze plate of graphite. The bronze plate acts as a slide plate for the pipe support sliding bearing. Piping system sliding bearings consist of a graphite-filled bronze slide plate and an upper and lower sliding plate assembly. The sliding plates are usually arranged in a “hamburger” pattern. The lower sliding plate may also be welded to a fixed support, thereby grounding the sliding plate. The other plate, on the other hand, is attached directly to the moving part. As the system moves, frictional forces are transmitted at the intersection of the two plates.

Bronze slide bearing plates advantages

Plugged graphite slide plate are primarily used in applications where continuous lubrication is required in hard-to-reach areas. The graphite is mechanically pressed into the bore/slot under extreme pressure. As the shaft begins to rotate, a layer of lubricant is transferred to the shaft. These bearings provide long term continuous lubrication without the need for maintenance.

Bronze slide graphite plates filled with graphite solid lubricant plugs can handle temperatures up to 500 degrees Fahrenheit. Bronze wear graphite slide plates are also suitable for high pressure systems. Sliding plate bronze graphite offer the following additional advantages.

- Ability to operate completely dry, no lubrication required.

- Ability to withstand a wide range of environmental conditions.

- Ability to withstand a wide range of organic and inorganic chemicals.

- Ability to tolerate the embedding of small particles without causing failure.

- Long life and maintenance free.

Graphite plug bronze slide bearing plate, bronze Alloys, Reasons for choosing plug graphite self-lubricating slide plate

1. Completely self-lubricating slide plate. No oil or grease required

The self-lubricating feature allows bearings to be used where oiling is difficult, implementation costs are high, and where grease/oil cannot be used. Good lubrication can be achieved even at low speeds and high loads.

2. Slide plate Excellent wear resistance.

Excellent wear resistance can be achieved under severe operating conditions such as heavy load, low speed, reciprocation, oscillation and intermittent motion where it is difficult to form an oil film.

3. Low coefficient of friction. 0.04 to 0.2 typical.

Self-lubrication slide plate with a specially embedded solid lubricant reduces friction.

4. Wide operating temperature range. -415°° to 1100° F

Excellent performance in both high and low temperature conditions.

5. Corrosion and chemical resistance.

Performance is unaffected by water and corrosive chemicals.

6. Designed to exceed your requirements.

High precision products with tight tolerances.

7. Cost competitive.

Reduced costs for maintenance, replacement and end equipment downtime compared to similar self-lubricating bearing bushing due to their extra-long service life.

Wear Plates Made up of C86300 Manganese Bronze, C93200 Bronze Slide Plate Batch & small MOQ slide plate production!

Shop for all your Oil-Free Slide Plates and Bronze Slide Plates needs. We offers free CAD download, short lead times, competitive pricing, ….Supply self-lubricating copper slide plate, self-lubricating slide plate, mold wear block bronze with graphite solid friction no lubrication drip oil lubrication processing JSP copper-based self-lubricating slide bearing plate,self-lubricating guide plate ,oil-free slide plate, non-standard size can be customized.

Sliding elements with solid graphite lubrication, Sliding elements

These components are widely used in:

- Automotive industry: Where they function as tool guides and in auto body presses.

- Plastic injection molding machines and injection molding tools: For seamless, high-precision molding operations.

- Mechanical engineering, steelmaking plants, and rolling mills: Providing reliable, maintenance-free components for large-scale industrial machinery.

- Construction and brick industries: Supporting the manufacture and handling of heavy-duty materials.

- Dam systems and hydro-power engineering: Ensuring smooth operation in demanding environments.

- Shipbuilding: Serving as robust, corrosion-resistant parts for sea vessels.

- Welding technology: Withstanding high temperatures and providing low-friction surfaces for welding operations.

- Packing industry: Offering smooth, wear-resistant surfaces for packing and material handling operations.

- Crane and conveying engineering: Contributing to the smooth and efficient operation of lifting and conveying systems.

Our sliding elements offer numerous advantages:

- Environmentally compatible: Manufactured with eco-friendly practices and materials.

- Maintenance-free: No need for regular servicing or replacement, reducing downtime and costs.

- Wear-resistant: Designed to withstand long-term use without degradation in performance.

- Low friction: Reducing heat and wear, extending the service life of both the slide elements and the machines they’re used in.

- High-temperature loading: Can withstand temperatures up to roughly 200 °C, making them suitable for use in high-heat environments.

- Corrosion-resistant: Resistant to rust and corrosion, ensuring longevity even in challenging environments.

- Resistant to impact loads: Can handle sudden or intense forces without breaking or deforming.

- Long service life: Thanks to all of the above features, our sliding elements are built to last, reducing the total cost of ownership over time.

We pride ourselves on the quality and performance of our sliding elements. With their superb features and benefits, they serve as a key component in numerous industries, helping ensure smooth operations and long-lasting performance.

CuAl10Fe5Ni5, also known as Aluminum Bronze C63000 or C63020, is a high-strength copper-aluminum alloy with additional iron and nickel content. It is widely used in various industrial applications due to its excellent mechanical properties, corrosion resistance, and wear resistance. Here is a brief overview of its characteristics and applications.

Composition:

- Copper (Cu): 78-81%

- Aluminum (Al): 9-11%

- Iron (Fe): 4-6%

- Nickel (Ni): 4-6%

- Other elements (such as Mn, Si, Zn): ≤ 0.5%

Properties:

- High strength and hardness: CuAl10Fe5Ni5 has superior mechanical strength and hardness, making it suitable for heavy-duty applications.

- Excellent wear and corrosion resistance: The alloy exhibits good resistance to wear and corrosion, particularly in seawater and other aggressive environments.

- Good thermal conductivity: Although not as high as pure copper, CuAl10Fe5Ni5 has good thermal conductivity.

- Moderate electrical conductivity: The alloy has moderate electrical conductivity compared to pure copper.

Applications:

- Marine industry: CuAl10Fe5Ni5 is commonly used for components that require corrosion resistance in seawater environments, such as propellers, pump components, and valve bodies.

- Aerospace: Due to its high strength and wear resistance, the alloy is utilized in landing gear bushings, bearings, and other critical components.

- Heavy machinery: CuAl10Fe5Ni5 is suitable for manufacturing heavy-duty components like gears, worm wheels, and bushings that require high wear resistance.

- Oil and gas: The alloy’s excellent corrosion resistance makes it an ideal choice for components exposed to harsh environments, such as valves, pumps, and fittings.

- Chemical industry: CuAl10Fe5Ni5 is used in chemical processing equipment like heat exchangers, pumps, and valves.

CuAl10Fe5Ni5 (Aluminum Bronze C63000 or C63020) is a high-strength copper-aluminum alloy with additional iron and nickel content, offering excellent mechanical properties, corrosion resistance, and wear resistance. It is widely used in various industries, including marine, aerospace, heavy machinery, oil and gas, and chemical processing.

The self-lubricating graphite slide bearing material consists of highly wear-resistant copper and brass alloys with sliding surfaces uniformly packed with “macro-distributed” solid lubricant deposits. Depending on the motion sequence, it must be ensured that the sliding plugs are sufficiently coated to build up a transmission film for stable plain bearing operation. The high density of the bronze ensures high load capacity and at the same time a great ability to embed any dirt particles in the lubricant reservoir. Two graphite-based plugs and a PTFE-based plug variant are available. In technically dry operation, the graphite sliding bearing provides a 10 to 20 micron thick wear film that transfers the solid lubricant to the corresponding material even at the first contact of the sliding partners.

The use of inlay bearing and slide bearing plate.

Inlaid bearings and slide bearing plates because of the use of solid lubricants inlaid in the skeleton, self-lubricating friction operation, very ideal solution to the liquid lubricating oil in the lubrication process, resulting in pollution problems, so widely used in food machinery, pharmaceutical machinery, and other equipment without pollution environment. The solid lubricant used in the inlay bearing and slide bearing plate has the characteristics of bearing load, so it is very suitable for heavy load, low speed, high temperature, water vapor, and other corrosive and inconvenient often refueling lubrication working conditions, and is now used in mining, metallurgy, petroleum, geology, chemical industry, paper making, bridge, hydraulic hub, ship, aerospace, and other industrial sectors. The most prominent effect, such as the steel mill’s iron ladle crane and 1150 primary rolling mill, then with the original shaft tile life increased by 6-8 times. A variety of rolling mills, shearing machines, cold bed slide bearing plate(steel pipe pulling car), pharmaceutical machines, stranding pots, rubber refining machine shaft tiles, floating crane bearings, textile factory dryers, non-ferrous metal mill, heavy automobile steel plate shaft pin sleeve, chemical plant stranding pot, coal mine conveyor roller bearing, drilling machine deep rod pump inner sleeve, protection drill rod sleeve and various equipment on the guide sleeve, slide bearing plate, cam plate, etc. The effect is very obvious.

Inlaid slide bearings, and slide bearing plate instructions for use.

(1) inlay bearings, and slide bearing plate in the factory before the friction surface has been coated with a layer of special grease. Do not dirty the friction table when installing. Do not wipe off the fat! If in case it is wiped off, please use lithium molybdenum disulfide grease instead of re-coating, but the test run must be run at low speed for a period of time before regular operation when using large load equipment, you must buy special grease from the seller manufacturer to recoat.

(2) installation of inlaid bearings, must ensure a certain sliding clearance, to prevent jamming, bad bearings, and machine parts.

(3) installation of inlay bearing, should ensure that the shaft diameter with the friction has a good cylindrical degree, so that it has a full contact area with the bearing, otherwise it will seriously affect the service life of the bearing or immediately damaged it.

Casting production of Bronze Wear Plate, Manufacturing sliding plate, casting bronze graphite material sliding pad

Cold rolling mill is a new type of steel cold rolling processing equipment. A cold rolling mill is composed of a working mechanism and a transmission mechanism. Among them: 1, the working mechanism consists of the frame, rolls, roll bearings, roll adjustment mechanism, guide device, rolling seat, and other parts. 2, the transmission mechanism consists of gear seat, reducer, rolls, coupling shaft, coupling joint, and other parts.

A copper slide is a groove or ridge made of metal or other materials that can bear, fix, and guide the moving device or equipment and reduce its friction. The longitudinal groove or ridge on the surface of the guide rail is used for guiding and fixing machine parts, special equipment, instruments, etc. The guide rail is also known as slide rail, linear guide, linear slide rail, used for linear reciprocating motion occasions, has a higher load rating than linear bearings, at the same time can bear a certain torque, can achieve high precision linear motion under high load.

The material of the copper slide for steel rolling equipment produced by our factory is mainly aluminum bronze, aluminum bronze is a copper-aluminum alloy with aluminum as the main element, but the aluminum content is generally not more than 11.5%, and sometimes the right amount of iron, nickel, manganese and other elements are added. With high mechanical properties, good corrosion resistance in the atmosphere, fresh water, and seawater, high strength wear-resistant rolling mill copper slide casting performance, dense organization, high airtightness, good wear resistance, and work in higher sliding performance conditions.

Supply cold rolling equipment accessories for large copper sliding plates, production casting various specifications of various materials copper sliding plate, copper guide, copper slider, self-lubricating sliding plate, the company has good product quality, low prices, timely delivery, welcome to map processing.

The way we cast copper sliding plates is mainly sand casting. Sand casting – A casting method that produces castings in a sand mold. Steel, iron, copper, and most non-ferrous alloy castings can be obtained by sand casting method. Due to the inexpensive and easy-to-use modeling materials used in sand casting, the mold is easy to manufacture and can be adapted to single-piece production, batch production, and mass production of castings, which has long been a basic process in casting production.

Sand casting is generally made of a combination of sand and core. In order to improve the surface quality of the castings, a layer of paint is often brushed on the surface of the sand and core. The main components of the coating are powder material and binder with high refractoriness and high-temperature chemical stability, plus a carrier (water or other solvents) and various additional substances for easy application.

Professional manufacturer of copper skids and self-lubricating skids, bulk supply of copper skids and self-lubricating skids for cold rolling mill accessories, if necessary, welcome to map processing.

Oil-Free Slide Plates – Oilless Sliding Plate bronzelube.com

Applications Include Oilless Sliding Plate Guide Bushes & Lifeboat Release Bearings. The Dry Running Capability Of Performance Reduces Maintenance Requirements. Enquire Today. Long Wear Life. Low Friction. Easy Installation. Propeller Shaft Bearings.

Custom Bronze Wear Plates Available, Professional Sliding Plate supplier, We are an exporter of mold and die components. Manufacturer Of Oilless Bronze Wear Plates, Custom Size Wear Plate Solutions. Offshore Industry Slide Plate – High Wear Resistance – bronzelube.com, Order Highest Quality Slide Plates Today For Super Fast Shipping. Size – Thickness – mm, Width – mm & Length – mm with lubricating holes. With numerous Oil-Free Slide Plates options available, selecting the right Oil-Free Slide Plates can be daunting. Download this sliding bearings catalog to check how to choose the right bearing type for your application.

Custom bronze plate products, Flat plates, self-lubricating, Price and delivery time on request

Oil-Free Slide Plates-Material-Copper Alloy

(High Strength Brass / Copper Alloy + Solid Lubricant)

Special Solid Lubricant Embedded

Guide to oil-free slide plates

Oil-free components are manufactured by embedding a special solid lubricant at suitable points.

The metal base material carries the load, while the embedded solid lubricant provides lubrication, resulting in superior lubrication

Oil-free durability even under harsh conditions.

Oil-free slide plates Feature

- These products are effective in places that require a constant supply of grease and in molding areas oil film is difficult due to reciprocating movement or frequent starts and stops.

- Because these products are used in oil-free conditions, no lubricating device is required. It shortens assembly time and leads to a cleaner environment, preventing oil contamination and other problems.

- These products have excellent resistance to seizure.

Oil-free slide plates range of oilless plates are available in metric & imperial sizes.

Oil-free slide plates Type

1-hole type, 2-hole type, 3-hole type, 4-hole type, 6-hole type, 8-hole type, 10-hole type.

Oil-free slide plates Accessories、Oil-Free Slide Plate Size

Oil-Free Slide Plates Properties

| Sliding speed v | 30 m/min |

| Base Material | Special Brass (Oil-free Slide Plates) |

| Self-lubricating | Yes |

| Lubricant: | Graphite |

| Surface Pressure P: | 100 N/mm² |

| P*v-value: | 200 N/mm² x m/min |

| Operating temperature: | -50°C / +200°C (max. 300°C) |

| Friction coefficient: | 0,07 |

Oil-Free Slide plates or Slide bearing plates are used in a wide range of applications and are generally used to support pipes, pressure vessels and heavy equipment. The slide plate allows for easier movement on the surface of the supporting object, providing a surface with a low coefficient of friction.

Oil-Free Slide Plates – Precision Mold Parts Supply in China

Quality Graphite Bronze Bushing Supplier, Oil-free Slide Plates – Guide Component

Oil-free Slide Plates Advantages

- Maintenance-free

- Withstands extreme pressures and high temperatures

- Self-lubricating

- High wear resistance

- The lubrication does not deteriorate with wear

- Extended life

- Prevents unwanted accumulation of dust and dirt

Application

Oilless Sliding Plate for universal use in many dry applications such as molds/molds, machines, automation, construction, and automotive. Oil-free is self-lubricating and works without grease.

Oilless Graphite Slide Plates, Oil-Free Slide Plates-High Surface Pressure Copper Alloy

Offshore oil rigs are a big mystery

Petroleum products are very common in our life, the fuel for cars comes from petroleum, the asphalt for paving comes from petroleum, and even the plastic and synthetic rubber products that can be seen everywhere around us are all inseparable from petroleum.

So, how is oil, which is so widely used, extracted from the deep underground and turned into a barrel of oil raw materials?

When we think of oil extraction, we often think of scenes like this.

Onshore oil extraction

However, in recent decades, another form of oil extraction has been developing: through offshore oil rigs. This type of extraction is far from human settlements and has great potential.

An oil rig hanging out at sea

This oil rig is like a flat boat, silently standing on the ocean. When you look closer, you will see that it is a huge thing.

Huge oil rig

This huge offshore platform can be roughly divided into four areas, not only to complete the work of drilling for oil in the deep sea, but also to provide the necessary life support for all the people on the platform.

Platform Area Division

The huge offshore oil drilling platform.

A slider part of the drilling equipment is broken, causing a part of the platform to stop working, replace it with a new slider part, and after the graphite slider part is replaced, the platform resumes operation.

The oil is buried in the deep seabed, it is difficult for humans to reach there, so he will be on the platform to manipulate the instruments to control the mechanical arm to operate at a depth of more than 8,000 meters.

Remote control of robotic arm operation

The offshore oil platform operates 24 hours a day, so whenever night falls, the platform is always lit up.

Oil free slide plate, graphite plate, Compact Oil-Free Slide Plates - Copper Alloy, 10mm

Shop for all your Oil-Free Slide Plates and Oil-free Slide Plates needs. We offer free CAD download, short lead times, and competitive pricing, ...Oil-free slide plates, graphite plates, and compact oil-free slide plates made from copper alloys are essential components in various industries where low friction and maintenance-free operation are required. These plates are commonly used in applications such as machine tools, automation equipment, and material handling systems. By providing a smooth and wear-resistant surface, they help reduce friction between moving parts, improve efficiency, and extend the service life of the equipment.

Oil-free Slide Plate Graphite Embedded Plate Configure & purchase

Oil Free Slide Plates – Configure and purchase- . graphite slide plate✓ Fast delivery ✓ Fair prices ✓ Free CAD data, oil-free components are produced by embedding a special solid lubricant at appropriate locations. Shop from bronzelube.com for all your Oil-free Slide Plates and Guide Components needs from China. We offer free CAD download, short lead times, competitive pricing, and small minimum order.

Features of Oil-Free Slide Plates:

- Low friction: Graphite and copper alloy materials provide low friction coefficients, reducing energy consumption and improving the efficiency of the equipment.

- Maintenance-free: Oil-free slide plates require minimal maintenance, as they do not need regular lubrication, making them ideal for applications where access is limited or contamination is a concern.

- High wear resistance: These slide plates exhibit excellent wear resistance, increasing the service life of the equipment.

- Versatility: Oil-free slide plates are available in various sizes and materials, making them suitable for a wide range of applications.

Purchasing Oil-Free Slide Plates: When looking for oil-free slide plates, consider the following factors to find the best product for your needs:

- Material: Choose the appropriate material based on the operating environment and required properties. Common materials include graphite, copper alloys, and engineered plastics.

- Size: Select the appropriate size based on the dimensions of your equipment and the required load capacity.

- Load capacity: Determine the load capacity needed for your application to ensure the slide plate can withstand the forces it will encounter during operation.

Shop for Your Oil-Free Slide Plates: To find the best oil-free slide plates for your needs, consider working with a reliable supplier that offers a wide range of products, free CAD downloads, short lead times, and competitive pricing. This will allow you to compare different products and select the one that best meets your application requirements. Additionally, a reputable supplier will provide technical support and assistance to help you make the right choice.

In summary, oil-free slide plates, graphite plates, and compact oil-free slide plates made from copper alloys are essential components for applications requiring low friction and maintenance-free operation. When shopping for these products, consider factors such as material, size, and load capacity to find the best solution for your needs. Work with a reliable supplier that offers a wide range of products, free CAD downloads, short lead times, and competitive pricing to ensure you get the best value for your investment.

Bronze Slide Bearing Material composition and performance table

| Material composition and performance table | |||||||

| Material code | (600#) | (600#S1) | (600#S2) | (600#S3) | (600#S4) | (HT250) | (Gcr15) |

| Chemical composition | CuZn25AI5Mn3Fe3 | CuZn25AI5Mn3Fe3 | CuAI9Fe4Ni4Mn2 | CuSn5Pb5Zn5 | CuSn12 | HT250 | Gcr15 |

| Density(g/cm3) | 8.0 | 8.0 | 8.5 | 8.9 | 9.05 | 7.3 | 7.8 |

| Hardness (HB) | >210 | >250 | >150 | >70 | >80 | >190 | HRO58 |

| Tensile strength (N/mm2) | >750 | >800 | >800 | >200 | >260 | >250 | >1500 |

| Elongation (%) | >12 | >8 | >15 | >10 | >8 | >5 | >15 |

| Linear expansion coefficient | 1.9 | 1.9 | 1.9 | 1.8 | 1.8 | 1.0 | 1.1 |

| Operating temperature(°C) | -40〜+300°C | -40-+150°C | -40〜+400°C | -40〜+400°C | -40〜+400°C | -40〜+400°C | -40〜+400°C |

| Maximum dynamic load(N/mm2) | 100 | 120 | 150 | 60 | 70 | 80 | 200 |

| Maximum line speed(m/min) | 15 | 15 | 20 | 10 | 10 | 8 | 5 |

| Maximum PV value Lubricating (N/mm2*m/min) | 200 | 200 | 60 | 60 | 80 | 40 | 150 |

| Permanent compression deformation 300N/mm2 | <0.01 | <0.005 | <0.04 | <0.05 | <0.05 | <0.015 | <0.002 |

Unveiling the Future of Production Automation: The Sliding Plate Technology

Subtitle: Accelerating Innovation in Robotics, Software, and Custom-Built Machines

The manufacturing industry is in the midst of a revolution, powered by innovative technologies like automation, robotics, and software. Sliding plate technology is one such innovation that is pushing the boundaries of production automation, offering unprecedented levels of efficiency and adaptability in various industrial applications. This article explores the critical role of sliding plate technology in production automation, robotics, software, and custom-built machines, and highlights its potential to transform the manufacturing landscape.

Sliding Plate Technology: The Basics

Sliding plate technology is an advanced mechanical system that facilitates the smooth and precise movement of machine components along a predefined path. The technology is particularly effective in high-speed production environments, where precise positioning and smooth motion are crucial for maintaining efficiency and accuracy. By employing low-friction materials and unique designs, sliding plate systems minimize wear and tear, reduce maintenance requirements, and maximize the lifespan of the equipment.

Integration with Robotics and Automation

The integration of sliding plate technology with robotic systems and automation has led to significant improvements in production efficiency and product quality. Modern robots equipped with sliding plate systems can execute complex tasks with unparalleled precision and speed, while also reducing the need for manual intervention.

In addition, sliding plate technology enables faster and more accurate movements, allowing robots to handle delicate and intricate tasks with ease. By improving the performance of robotic systems, sliding plate technology is transforming production lines across industries, from automotive manufacturing to electronics assembly.

Software and Custom-Built Machines

The potential of sliding plate technology in custom-built machines is immense, especially when combined with advanced software solutions. Sophisticated software algorithms can optimize the motion of sliding plate systems, ensuring that machine components move in the most efficient and precise manner possible. This software can also monitor the performance of the sliding plate system, detecting any potential issues and enabling proactive maintenance.

Custom-built machines equipped with sliding plate technology can be tailored to the specific needs of a production process, maximizing efficiency and flexibility. These machines can be easily adapted to new production requirements or integrated with existing systems, making them a valuable investment for manufacturers seeking to stay competitive in a rapidly evolving industry.

The Future of Sliding Plate Technology

The future of sliding plate technology is promising, with new developments and innovations poised to further enhance its capabilities. For instance, advancements in material science are expected to lead to the development of even lower-friction and more wear-resistant materials, enabling sliding plate systems to operate with even greater efficiency and durability.

Furthermore, as machine learning and artificial intelligence continue to evolve, we can anticipate the development of even more advanced software solutions for optimizing sliding plate performance. This will undoubtedly drive further improvements in production automation, robotics, and custom-built machines.

Sliding plate technology is playing a critical role in shaping the future of production automation, robotics, software, and custom-built machines. As the manufacturing industry continues to embrace innovative solutions, sliding plate technology is poised to remain at the forefront of this revolution, offering manufacturers the tools they need to increase efficiency, improve product quality, and maintain a competitive edge in a rapidly changing landscape.

Slide Bearing Alloy Material

| Alloy Material | |||||||

| Model / corresponding grade | |||||||

| International brand GB1776-87 | ZCuZn25 AI6Fe3Mn3 | ZCuSn6Zn6Pb3 | ZCuAI10Fe3 | ZCuSu10P1 | Steel ZCuSn6Zn6Pb3 | HT250 | GCr15 |

| International ISO1338 | GCuZn25 AI6Fe3Mn3 | GCuSn6Zn6Pb3 | GCuAI10Fe3 | — | Steel CuSn6Zn6Pb3Fe3Ni5 | — | B1 |

| Germany DIN | G-CuZn25AI5 | GB- CuSn5Zn5Pb5 | GB-CuAI10Ni | GB—CuSn10 | Steek CuSn6Zn6Pb3Ni | — | 100Cr6 |

| Japan JIS | HBsC4 | BC6 | AIBC3 | BC3 | BC6 | FC250 | SUJ2 |

| United States ASTM/UNS | C86300 | C83600 | C95500 | C90500 | C83600 | Class40 | 52100 |

| British standard (BS) | HTB2 | LG2 | AB1 | PB4 | LG2 | — | — |

Slide Plate Bearing Products for the oil and gas

Slide plate graphite bronze plate is a type of material used for sliding or rotating pipe supports. It is designed to reduce friction and provide a smooth surface for pipes to move on.

we are leading manufacturer of slide plate graphite bronze plate for the oil and gas, petrochemical, and power industries. our self-lubricaing slide plate graphite bronze plate is made from a combination of graphite and bronze, which provides excellent strength and durability.

The graphite in the material acts as a lubricant, reducing friction between the pipe and the support. This helps to prevent wear and tear on both the pipe and the support, extending the life of both components.

The bronze in the material provides additional strength and stability, allowing the support to bear the weight of the pipe without bending or breaking. This is particularly important in high-pressure and high-temperature applications, where the support must withstand extreme conditions.

bronzelube’s slide plate graphite bronze plate is available in a variety of sizes and thicknesses to accommodate different pipe diameters and weights. It can be custom-designed to meet specific requirements, such as temperature, pressure, and load capacity.

Slide plate graphite bronze plate is easy to install and requires minimal maintenance, making it a cost-effective solution for pipe supports. Its durability and resistance to corrosion make it an ideal choice for harsh environments.

In conclusion, slide plate graphite bronze plate is an essential component of pipe supports, providing a smooth and durable surface for pipes to move on. Piping Technology Products is a trusted supplier of high-quality slide plate graphite bronze plates for a wide range of applications.

Slide Plate Bearing Solutions.

Slide-bearing plates are an essential component of many industrial and manufacturing applications. These plates are used to facilitate sliding or linear motion between two surfaces and are commonly used in machinery and equipment to reduce friction and wear.

Slide-bearing plates are typically made from materials such as bronze, composite materials, or plastic, which provide a low coefficient of friction and excellent wear resistance. These materials help to ensure smooth and efficient motion between two surfaces, reducing the risk of damage or failure.

One of the key benefits of slide-bearing plates is their ability to operate in harsh environments. In many industrial applications, the plates are subjected to high temperatures, high loads, and corrosive environments, making it difficult to maintain a consistent level of lubrication. Slide-bearing plates, on the other hand, are designed to function in these conditions without any additional lubrication, which makes them an ideal solution for a wide range of applications.

When choosing a slide-bearing plate for your application, it is important to consider a number of factors, including the maximum load, temperature range, and environment in which the plate will be used. In addition, it is important to choose a reputable manufacturer that can provide you with high-quality products that meet your specific requirements.

In conclusion, slide-bearing plates are a versatile and reliable component that can facilitate smooth and efficient motion between two surfaces. With their low friction, high wear resistance, and ability to operate in harsh environments, they are an ideal solution for many industrial and manufacturing applications where regular maintenance is difficult or where contamination of the lubricant can cause problems. When choosing a slide-bearing plate for your application, it is important to consider a number of factors and choose a reputable manufacturer that can provide you with high-quality products that meet your specific requirements.

High-quality graphite slide plate address customer requirements with performance standards so that our quality standards for wear plates provide the basis for product design and supply contract management.

“Solving customer’s procurement costs reduces downtime and self-lubricating maintenance-free slide plate. Achieving consistency in quality practices and results requires investment in developing deeper self-lubricating plain bearingplate solutions and customer relationships. It also requires a sophisticated understanding to think systematically about quality. Over the years, quality has informed so many of our team’s decisions that it has become deeply embedded, part of our corporate culture, and critical to the company’s value proposition.”

Today’s global customers demand not only high quality but quality leadership. We export high-quality self-lubricating slide plate items that meet or exceed our customers’ expectations: every product, every export shipment, every product, year after year.

“This is where the real value lies, not only in the higher revenues that result from increased customer satisfaction but also in the higher operational efficiency and effectiveness that result from lower maintenance time costs, increased productivity and quality collaboration.

With a culture rooted in progress, we have been working hard to build the capacity to take their business to new frontiers in the fundamentals of quality. The entire organization is immersed in capacity building sessions to understand the competitive reasons for improving quality and the impact on day-to-day work. A deeper approach to problem-solving led to a new way of serving customers from every touch point.

Quality is not primarily a matter of bottom-line savings, but rather a matter of generating top-line revenue. Each year, we are achieving higher quality at a competitive cost. In this way, our customers can expect an evolution in quality without a corresponding incremental price tag.”

The result is increased customer satisfaction, which is evident in the renewed growth of self-lubricating slide wear plate applications year after year. Customer Satisfaction.

When we customize and manufacture self-lubricating slide bronze plate bearings for our customers, we are impressed with our customer service and “can do” attitude. Our sales engineers in China provide technical support and quoting services.”

Quality manufactured self-lubricating plain bearings slide bearing plate place to service you can trust

It can be difficult to select a reliable, high-quality plain bearing and slide plate. As an export product manager, quality control and product tracking are key factors to consider, along with technical competence, overall pricing and personal customer service.

The good news is that selecting a supplier who understands quality to ensure accuracy and consistent standards need not be an extensive, time-consuming process.

Industry research has found that customers observe two widely perceived hallmarks the most.

Quality management systems

Lean manufacturing processes

Drivers of quality and continuous improvement

High-quality standards are ensured by a well-defined quality management system and lean manufacturing principles in every step of the manufacturing process.

We ensure that we manufacture the same precision slide wear plate parts time and time again with exacting detail.

The success of the projects we deliver is a testament to the capability of our bearing graphite slide plates and bushings to achieve the highest level of quality possible.

In addition to our quality management system, we have adopted lean manufacturing practices to improve production by continuously identifying and promoting value-added activities and eliminating non-value-added activities.

Working with us, customers can always expect economic and sustainable environmental benefits in several different ways

Overall cost reduction

Waste minimization

Quality assured manufacturing

Customer service

Speed of product delivery

Positive environmental impact

Knowledge-based service support

Satisfied customers from the plantation industry using our oilless graphite bearings bushings.

BRONZE ALLOYS AVAILABLE

Maintenance-free, self-lubricating sliding bearings material

Manufactured slide plate bearing assemblies for an oil refinery. The Bronze graphite slide plate materials used for this assembly are Bronze graphite (which is graphite-impregnated bronze), and bronze material serves as a self-lubricated slide-bearing surface. The assembly is designed for an operating high temperatures. with an operating high load. Standard dimensional tests were performed before delivery.

| TIN BRONZE | |||||||||||||

| Cross Index | Nominal Chemical Composition | Typical Mechanical Properties | |||||||||||

| CDA | Ingot | Former SAE | Former Federal | Former ASTM | Copper | Tin | Lead | Zinc | Tensile (psi) | Yield (psi) | Elongation % | BHN (TYP.) @ 500 KG | |

| C93200 | 315 | 660 | A-932 | 3B | 83 | 7 | 7 | 3 | 30,000 | 14,000 | 15 | 65 | |

| MANGANESE BRONZE | |||||||||||||

| Cross Index | Nominal Chemical Composition | Typical Mechanical Properties | |||||||||||

| CDA | Ingot | Former SAE | Former Federal | Former ASTM | Copper | Zn | Al | Fe | Mn | Tensile (psi) | Yield (psi) | Elongation % | BHN (TYP.) @ 500 KG |

| C86200 | 423 | 430A | (B) & (E) | 8B | 64 | 26 | 4 | 3 | 3 | 90,000 | 45,000 | 18 | 180 |

| C86300 | 424 | 430B | (C) | 8C | 63 | 25 | 6 | 3 | 3 | 110,000 | 60,000 | 12 | 225 |

| C86500 | 421 | 43 | (A) | 8A | 58 | 39 | 1 | 1 | 1 | 65,000 | 25,000 | 20 | 100 |

| LEADED MANGANESE BRONZE | |||||||||||||

| Cross Index | Nominal Chemical Composition | Typical Mechanical Properties | |||||||||||

| CDA | Ingot | Former SAE | Former Federal | Former ASTM | Copper | Sn | Pb | Zinc | Tensile (psi) | Yield (psi) | Elongation % | BHN (TYP.) @ 500 KG | |

| 864 | 420 | C2 | 7A | 59 | 1 | 40 | 60,000 | 20,000 | 15 | 105 | |||

| 867 | 422 | 58 | 1 | 34 | 80,000 | 32,000 | 15 | 155 | |||||

| ALUMINUM BRONZE | |||||||||||||

| Cross Index | Nominal Chemical Composition | Typical Mechanical Properties | |||||||||||

| CDA | Ingot | Former SAE | Former Federal | Former ASTM | Copper | AI | Fe | Ni | Mn | Tensile (psi) | Yield (psi) | Elongation % | BHN (TYP.) @ 500 KG |

| C95200 | 415A | 68A | 9A | 88 | 9 | 3 | 65,000 | 25,000 | 20 | 125 | |||

| C95300 | 415B | 68B | G7 | 9B | 89 | 10 | 1 | 65,000 | 25,000 | 20 | 140 | ||

| C95300HT | G7-HT | 89 | 10 | 1 | 80,000 | 40,000 | 12 | 160 | |||||

| C95400 | 415C | A-954 | 9C | 85 | 11 | 4 | 75,000 | 30,000 | 12 | 170 | |||

| C95400-HT | G5-HT | 9C-HT | 85 | 11 | 4 | 90,000 | 45,000 | 6 | 190 | ||||

| C95500 | 415D | G3 | 9D | 81 | 11 | 4 | 4 | 90,000 | 40,000 | 6 | 190 | ||

| C95500-HT | G3-HT | G3 | 81 | 11 | 4 | 4 | 110,000 | 60,000 | 5 | 200 | |||

| C95800 | 81 | 9 | 4 | 5 | 1 | 85,000 | 35,000 | 15 | 159 | ||||

| C95900 | 82 | 13 | 4 | 1 | 241 (MIN.) | ||||||||

1、No oil lubrication or less oil lubrication, suitable for places where it is impossible to add oil or very difficult to add oil, and can be used without maintenance or less maintenance.

2、Good wear resistance, small friction coefficient, long service life.

3, there is a moderate amount of elasticity, can distribute the stress in a wider contact surface, improve the bearing capacity.

4, static and dynamic friction coefficient is similar, can eliminate the crawling at low speed, so as to ensure the working accuracy of the machinery.

5、It can make the machinery reduce vibration, reduce noise, prevent pollution and improve labor conditions.

6、The transfer film can be formed during the operation to protect the shaft of the grinding, no gnawing phenomenon.

7、The hardness requirement for the grinding shaft is low, and the shaft without tempering treatment can be used, thus reducing the processing difficulty of related parts.

8、Thin-walled structure, light weight, can reduce the volume of machinery.

9、The back of the steel can be plated with various metals and can be used in corrosive media; it has been widely used in the sliding parts of various machines, such as: printing machines, textile machines, tobacco machines, micro machines, and so on.

Textile machines, tobacco machinery, micro-motors, automobiles, motorcycles and agricultural and forestry machinery, etc.

The purpose of slide graphite plates is to produce a low-coefficient of friction between a stationary support element and the moving pipe support component to reduce the forces generated as a result of pipe deflections during operation.

Function Slide plate

Shop Function Slide plate – Slide Plates at bronzelube.com. We offers FREE CAD download, short lead times and competitive pricing. Quote and order online today!