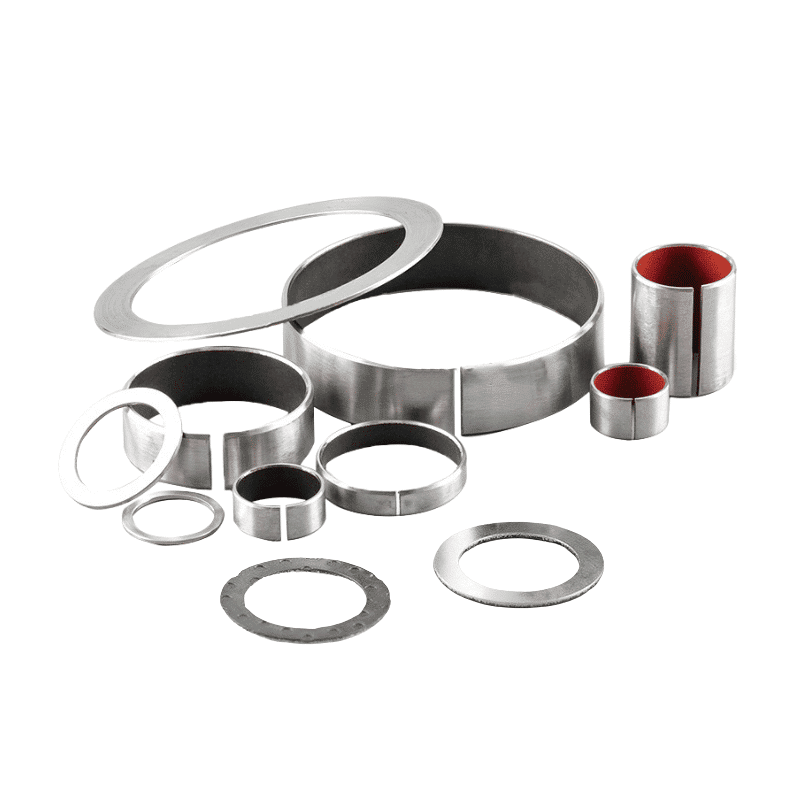

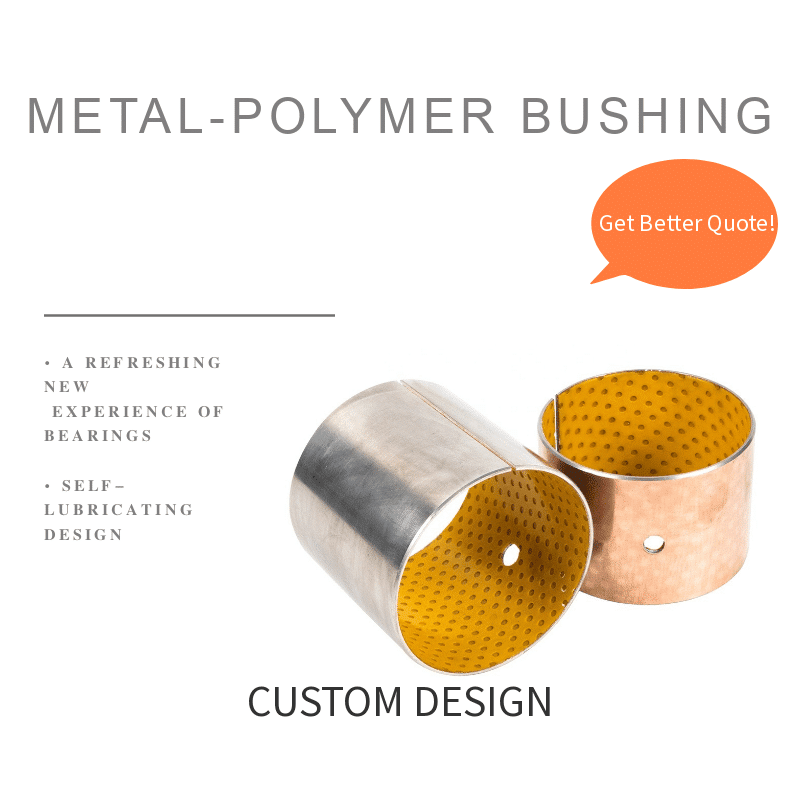

Composite Bushing Projects

Maintenance-Free POM Composite Bushing Supplier

“Bronzelube.com” is a leading provider of high-quality POM composite bushings, boasting a professional design and R&D team, with products exported worldwide.

The unique construction of our composite bushings features a steel backing, which offers enhanced mechanical strength, while the bronze interlayer provides a strong mechanical bond for the lining. This design not only promotes dimensional stability but also improves thermal conductivity, effectively reducing the temperature at the bearing surface.

Maintenance-free POM composite bushings advantages

Composite bushings are widely used in various industries due to their low friction, self-lubricating properties, and excellent wear resistance. POM (polyoxymethylene) composite bushings are particularly popular because of their maintenance-free nature and durability. A steel-backed bronze POM bushing is a type of composite bushing that combines a steel backing with a bronze layer and a POM surface layer, offering an optimal balance of strength, durability, and performance.

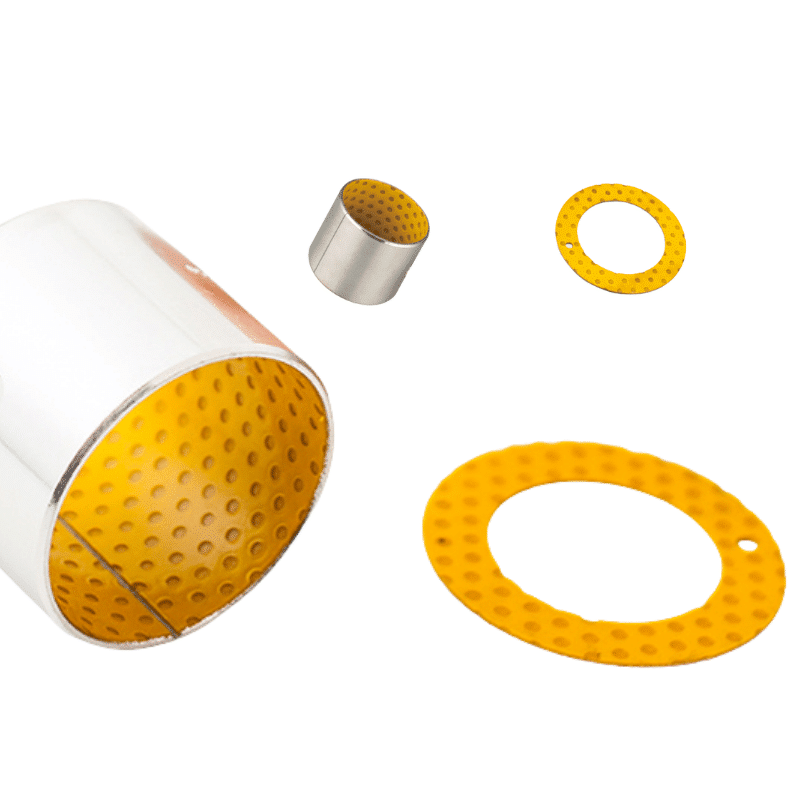

Sliding layer: acetal copolymer, with or without lubrication indents

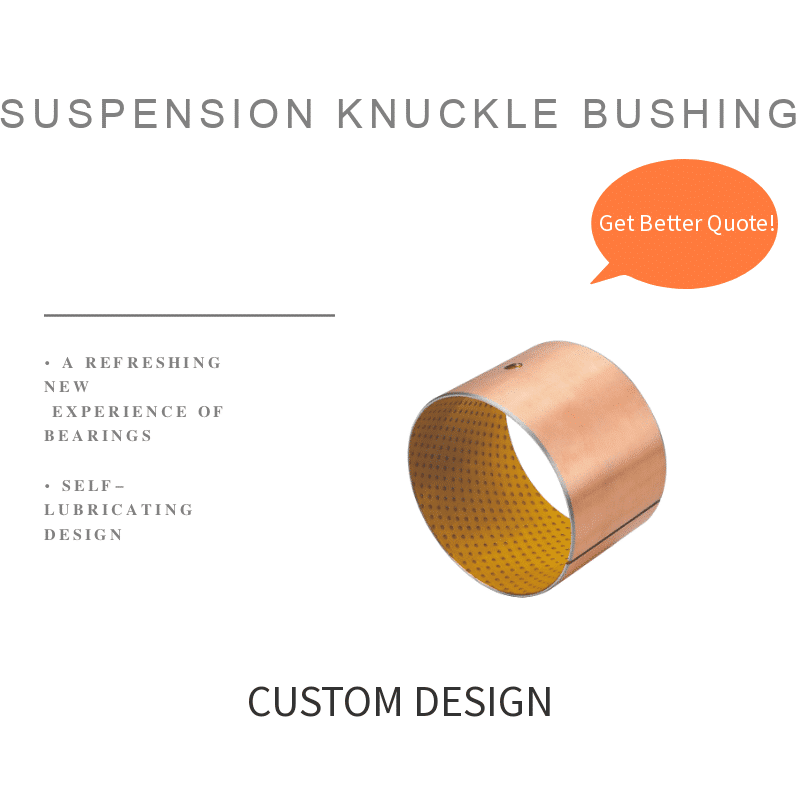

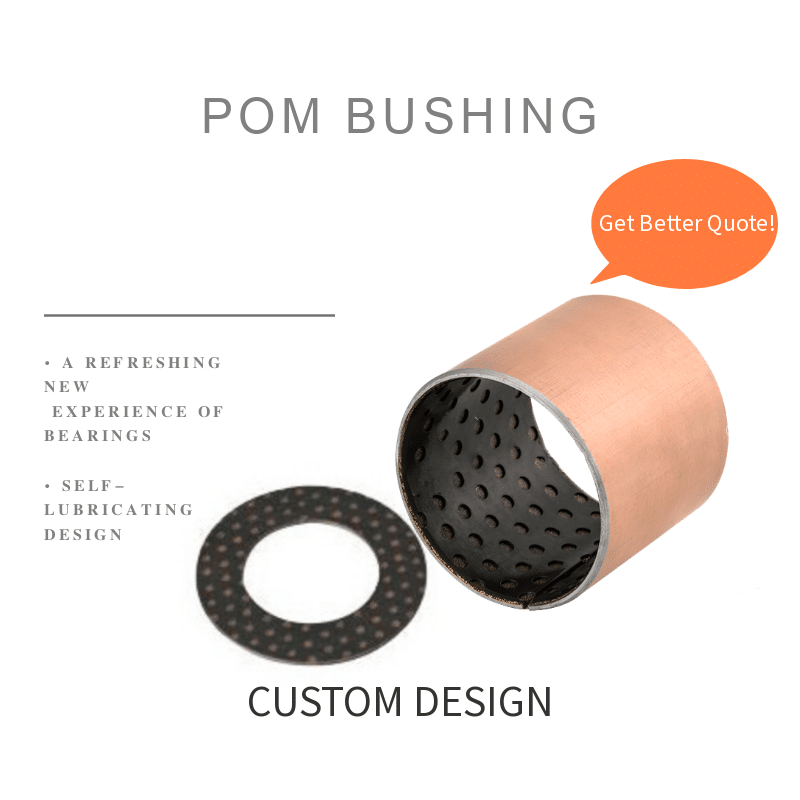

POM composite straight bushing requiring low-maintenance steel backing series

Sliding layer: acetal copolymer, with or without lubrication indents. Acetal copolymer, also known as polyoxymethylene (POM) or polyacetal, is a common engineering thermoplastic with excellent wear resistance, low friction, and good dimensional stability. POM bushings can be designed with or without lubrication indents. The lubrication indents serve to store lubricant, which can improve the wear life and reduce the coefficient of friction of the bushing.

POM composite straight bushing requiring low-maintenance steel backing series

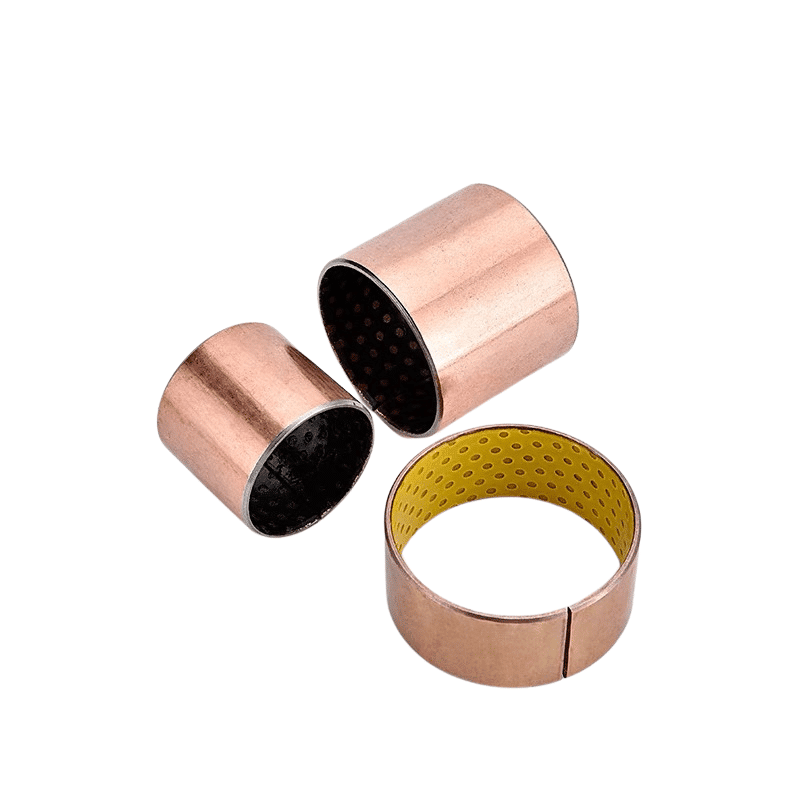

These bushings are made of a composite material with a steel backing layer for mechanical strength, a porous bronze powder layer for good bonding and heat dissipation, and a POM sliding layer for low friction and wear resistance. These bushings are low-maintenance and ideal for applications with infrequent or no lubrication.

Self-lubricating bearings steel backed bronze Bi-metal PTFE POM bushings

Self-lubricating bearings combine the properties of various materials to provide a low-friction, maintenance-free solution for a wide range of applications. These bearings often have a steel backing for strength, a bronze layer for heat dissipation and load distribution, and a sliding layer made of PTFE, POM, or other low-friction materials for optimal performance.

POM Composite Bushing Structure, Quality & Experience in Every Detail.

POM composite bushing structure: A POM composite bushing typically has a three-layer structure: Steel backing: This layer provides mechanical strength and support for the bushing. It also ensures proper load distribution and contributes to the bushing’s overall rigidity. Sintered porous bronze powder: This layer is bonded to the steel backing and acts as a strong intermediate layer. The porous nature of the bronze allows it to store and release lubricants, improving the wear resistance and performance of the bushing. Modified POM: The outer sliding layer is made of POM, which provides low friction and good wear resistance. This layer may also have lubrication indents or pockets to store and distribute lubricant across the bearing surface, further reducing friction and wear. POM composite plain bearings are designed to operate under marginal lubrication conditions. The sliding surface of these plain bearings contains greas. The POM composite bushing works well under working condition of low speed, heavy duty and normal temperature.

-

Cost effective

-

Longer service life

Grease-lubricated composite bearing

Grease-lubricated composite bearing is based on a composite material with 3 firmly bonded layers: Steel backing: Provides mechanical strength and support. Sintered porous bronze powder: Offers strong bonding and heat dissipation, as well as storage and release of lubricants.Modified POM: The sliding layer that provides low friction and wear resistance. When grease-lubricated, the bearing’s performance is further enhanced by reducing friction and extending the service life of the bushing. The POM composite bushing is widely used in many application:

- Auto chassis

- Forging machine

- Metallurgical and mining equipment

- Construction machinery

- Power station

- Strip rolling industries

- Others

* Our enterprise, is one of the undisputed supplier of the highly competitive order POM composite bushings industry in china.

POM Composite Bushings, Self-lubricating Bronze Bushings Composite Bushings Sourcing Service

POM Composite Bushings | Self-lubricating Bronze Bushings Composite Bushings Sourcing Service

POM bearings & bushings ISO 3547 Standard. Made to order from China. Pre-lubrication Bearing Manufacturer.

POM bearings and thrust washers have been specially developed for marginally lubricated applications and can function for extended periods with minimal lubrication.

Steel-Backed Bronze POM Bushes Composite Bearing Characteristics:

The POM bushes 3 sliding layer is designed for marginally lubricating bearings. It consists of a copper-plated steel backing with porous bronze sintered onto it and polymers (POM) incorporated into the bores of the bronze. The steel backing provides the products made by composite bearing with enhanced mechanical strength and load capacity. Oil indentations stamped on the surface of the polymer enable effective lubrication between the bearing and its mating axis. It offers excellent anti-abrasion and load capacity. The plating coating on the surface is corrosion-resistant. Moreover, it is environmentally friendly as no lead is included in the surface polymer POM.

Material and Composition:

- POM Lining: 0.3-0.5mm

- Porous Bronze Powder: 0.20-0.35mm

- Low Carbon Steel

- Tin plating or copper plating

Dimensions:

- Metric (mm) Imperial (inch) Bushing: Shaft and housing tolerances (Design of bushing arrangements)

- Housing ØH7

- Bushing inner-Ø after mounting in the range of D

- Shaft tolerance h8

Availability:

- Bearing forms available in standard dimensions

- Metric bearings and imperial bushings made to order: standard bushing forms in special dimensions, half-bushings, special shapes obtained by stamping or deep drawing, customized bushing designs

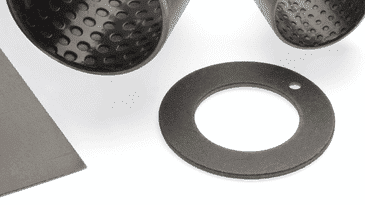

Shapes & Forms:

- Cylindrical bushes

- Flanged bushes

- Thrust washers

- Flanged washers

- Sliding plates

Boundary Lubricating Bearing Advantage:

- Good load and anti-wear capacity

- Suitable for rotational and oscillating motion or frequent start-stop with high load and low-speed conditions

- Can operate for an extended period without oil in boundary lubrication conditions; adding oil or grease during operation can prolong its service life

Range of Application: Composite bearing POM bushes series are widely used in automotive chassis, forging machines, mine quarrying machines, metal melting and casting machines, and water irrigation and steel rolling industries.

Special Manufacturing:

- Special dimensions are available upon request

POM Boundary Lubricating Bearing: For more information about our POM composite bushings or to request a quote, please feel free to contact us. Our team of experts is ready to assist you with your project needs.

Customized POM Composite Bushings Solution for Your Business

“Customized POM Composite Bushings Solution for Your Business.”

At our company, we specialize in providing customized POM composite bushings tailored to meet the unique needs of your business. Our engineering team works closely with you to understand your application requirements, ensuring that the bushings we design and manufacture will deliver optimal performance, durability, and cost-effectiveness.

Here’s an overview of our customization process:

-

Consultation: We begin by discussing your specific application needs, including load capacity, operating environment, temperature range, and lubrication requirements.

-

Material selection: Based on your requirements, we help you select the most suitable materials for the steel backing, sintered porous bronze powder, and modified POM sliding layer.

-

Design optimization: We can customize the bushing’s dimensions, shape, and lubrication indents or pockets to ensure optimal performance in your application.

-

Prototyping: Once the design is finalized, we create a prototype of the custom bushing to test and validate its performance. This allows us to make any necessary adjustments before proceeding to full-scale production.

-

Production: After the prototype is approved, we proceed with the mass production of your customized POM composite bushings, maintaining strict quality control to ensure consistent performance and reliability.

-

After-sales support: We stand by our products and offer after-sales support to address any concerns or questions you may have about the performance and maintenance of your custom POM composite bushings.

By providing customized POM composite bushings tailored to your specific needs, we help you achieve the best possible performance and longevity for your application. Contact us today to discuss your requirements and explore how our customized bushings can enhance your business operations.

Steel-backed bronze POM bushes

Steel-backed bronze POM bushes are a type of composite bushing that combines the strength and support of a steel backing, the heat dissipation and load distribution properties of a bronze layer, and the low friction and wear resistance of a POM (polyoxymethylene) sliding layer. These bushes are designed for a wide range of applications, including automotive, industrial machinery, and heavy equipment.

Key features of steel-backed bronze POM bushes:

-

Robust construction: The steel backing provides mechanical strength and rigidity, while the bronze layer offers good bonding and heat dissipation. The POM sliding layer ensures low friction and excellent wear resistance.

-

Low maintenance: The self-lubricating nature of the POM sliding layer, combined with the porous bronze layer’s ability to store and release lubricant, helps reduce the need for frequent lubrication and maintenance.

-

Versatility: Steel-backed bronze POM bushes are suitable for various applications, including those with high loads, oscillating or rotating motion, and variable temperatures.

-

Customizability: These bushes can be tailored to specific dimensions, shapes, and lubrication indents or pockets to meet the unique requirements of your application.

-

Long service life: The combination of materials and design features ensures a long-lasting and reliable performance, even in demanding operating conditions.

Steel-backed bronze POM bushes are an excellent choice for applications requiring low friction, durability, and minimal maintenance. They offer a cost-effective and high-performance solution for various industries, including automotive, aerospace, and heavy machinery. If you’re looking for a reliable bushing solution for your business, consider the benefits of steel-backed bronze POM bushes.