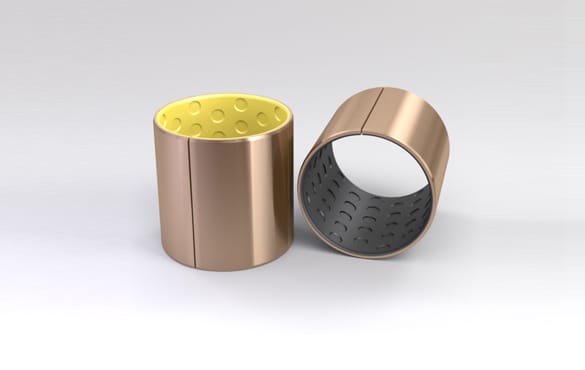

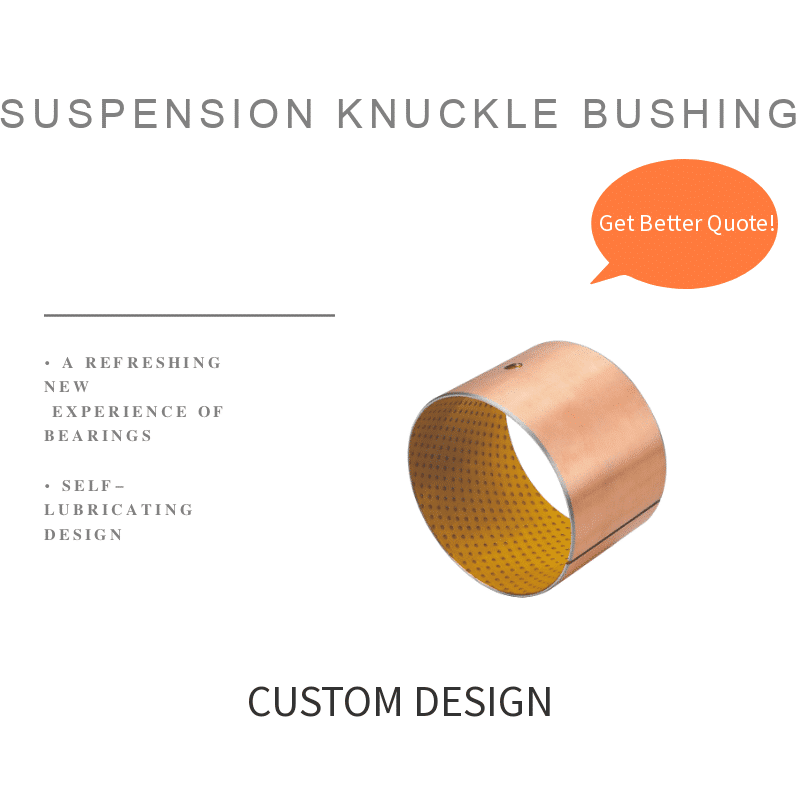

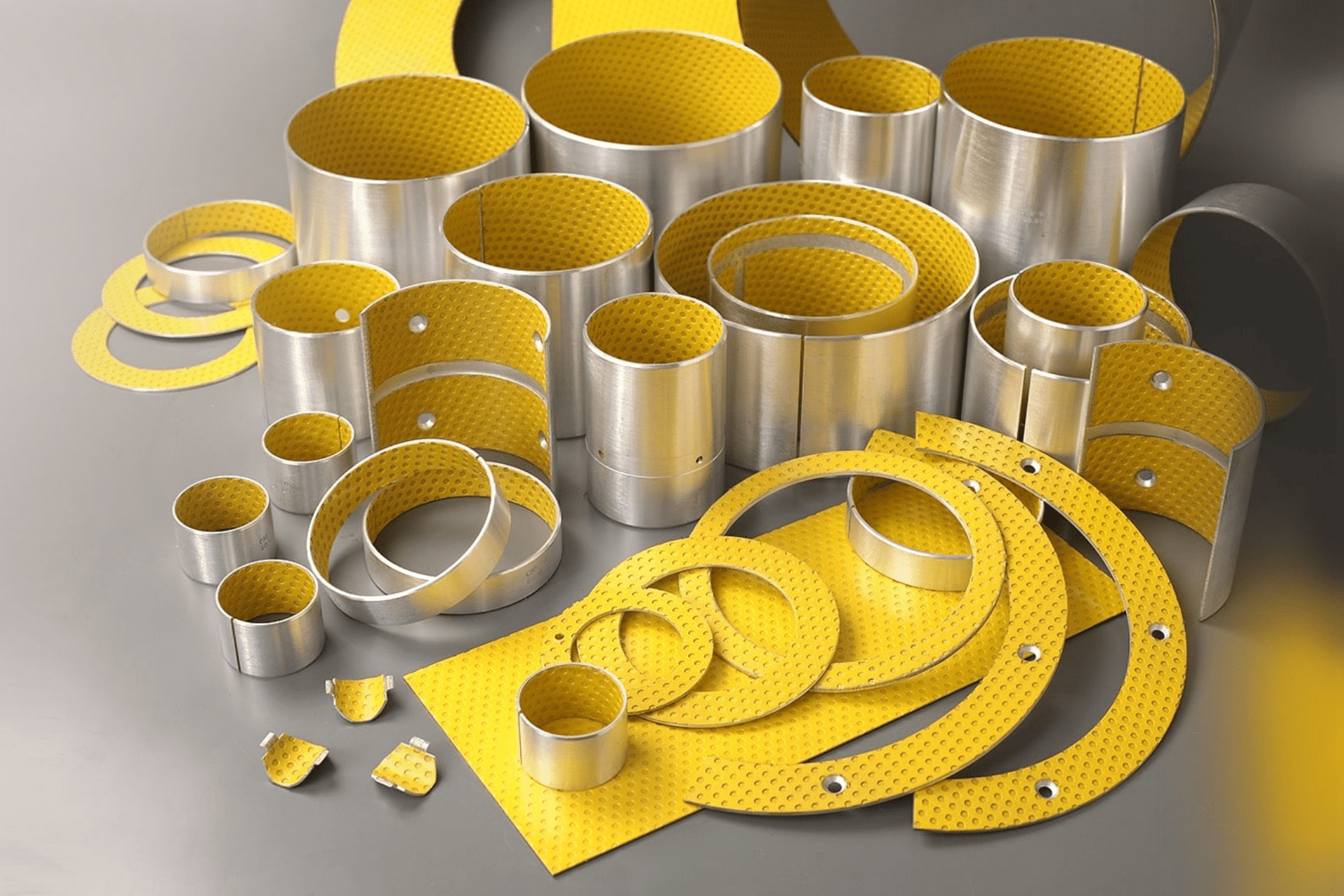

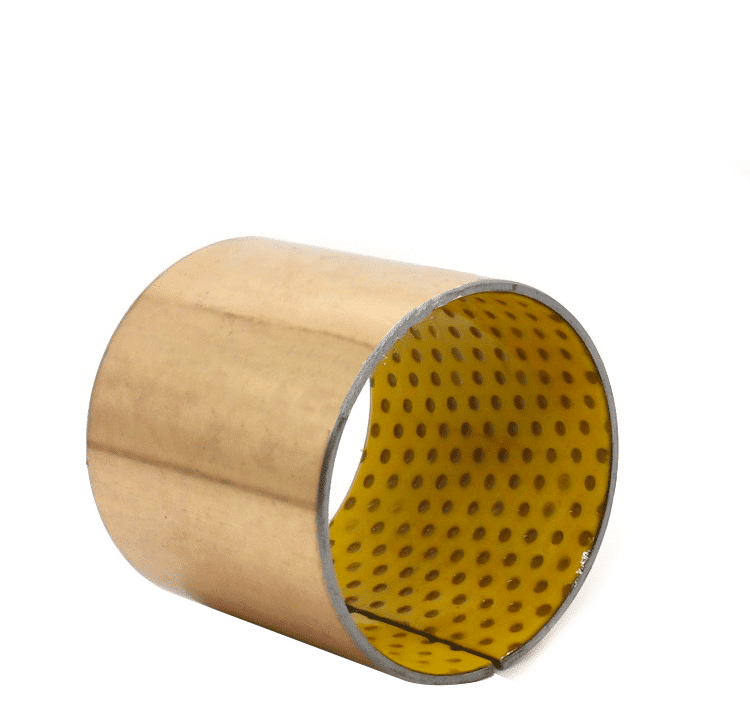

bushing: standard for marginally lubricated metal polymer plain bearings. Cylindrical bushes, thrust washers.

Composite bearings – For High Static, Dynamic Loads

We offers a wide range of high performance POM bearing materials, services and solutions. Find the right bearing for your application. Call our experts for more info. Easy assembly. Strives to Offer Cost-saving, Stable Performance Bearings and Bushings. Contact Us. 100% Quality Guaranteed. Worldwide On-time Shipping. View Our Products. COMPOSITION

- Metal-Polymer Composite Bushing Material

- Steel Back + Porous Bronze Sinter +

- POM with Lubrication Indents

Product Quality Index

Energy Generation

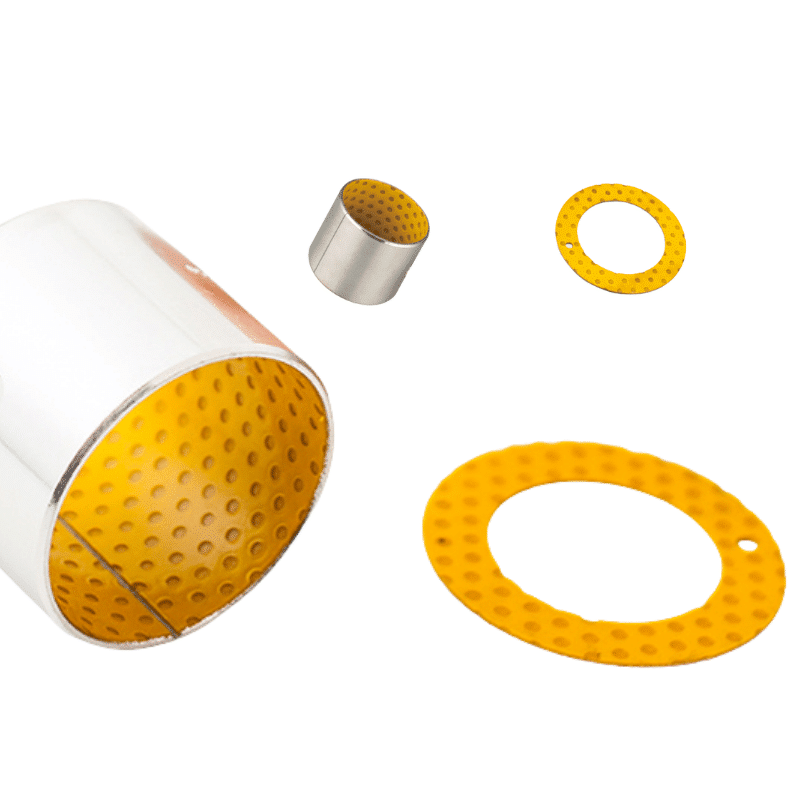

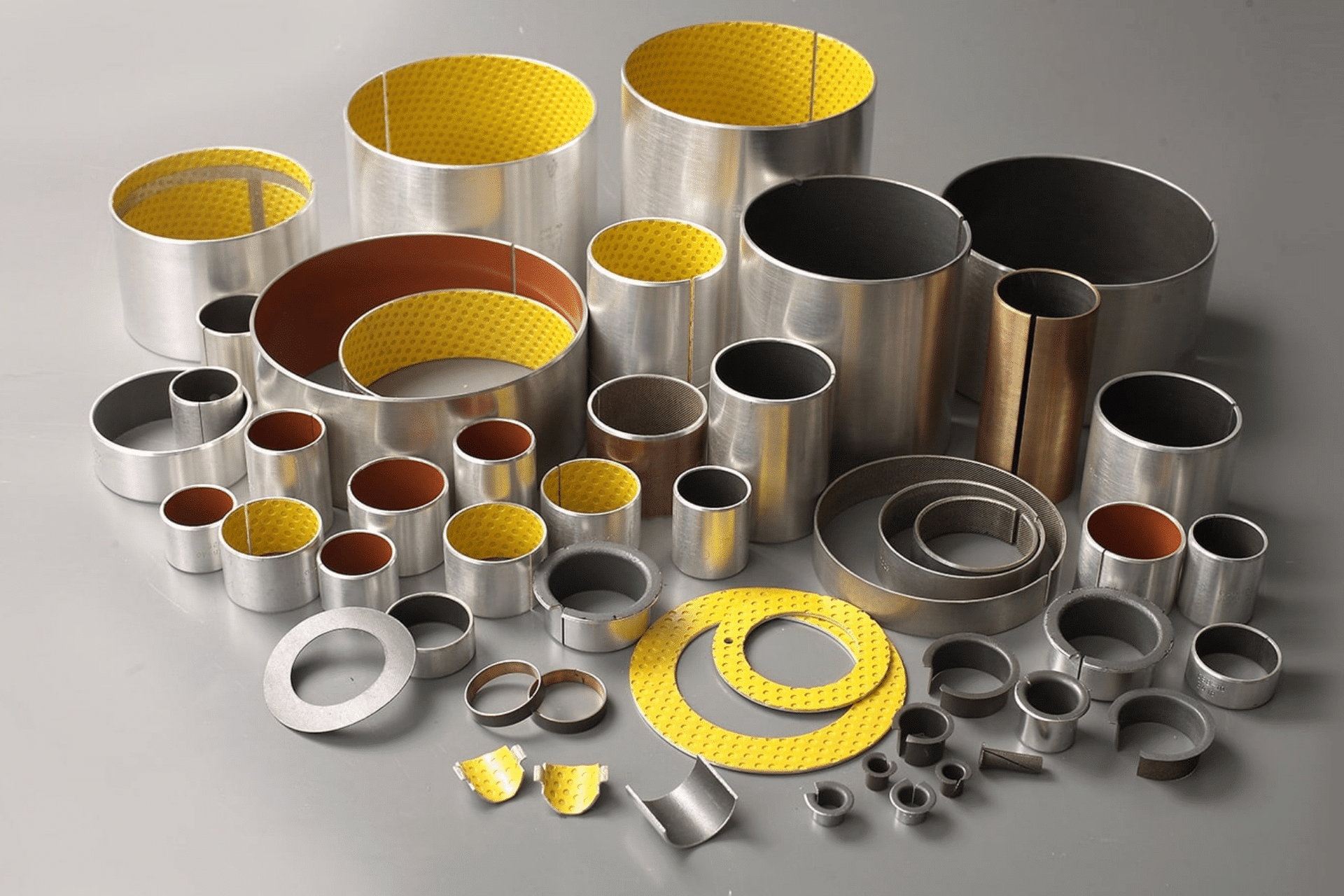

POM Bushes, POM composite strip

About Us

High shock and edge loading capacity. Corrosion resistant and dimensionally stable. Low-friction & wear-resistant fiber-reinforced bearings, ideal for corrosive…POM compound belts are suitable for linear, rotary and oscillating movements and can accommodate heavy loads. After initial grease filling, they are optimized for minimal maintenance under demanding operating conditions. Pockets in the sliding surface act as grease reservoirs. Self-lubrication can significantly extend the life of the bearing.

Oil Free Bushings(Resin Composite Bearing:POM (Polyacetal)) – Volume Discount

Plain composite bearing bushes / slotted, bronzelube.com, Composite Bearings, Straight bushing Low-maintenance Steel/POM Series,Composite bearings are a common alternative to nylon and plastic plain bearing materials. Composites are made from metal composites, metallic backed with PTFE lubricant and high performance sintered copper powder. Composite bearings are suitable for high load, low speed applications and are ideal for marine, hydroelectric and many industrial applications. Compared to many other non-metallic bearing materials, composites offer higher load capacity and better dimensional stability. When high strength, low friction and low wear are important, we are your best partner. Premium Composite Bearings for Marine, Hydropower & Industrial applications!

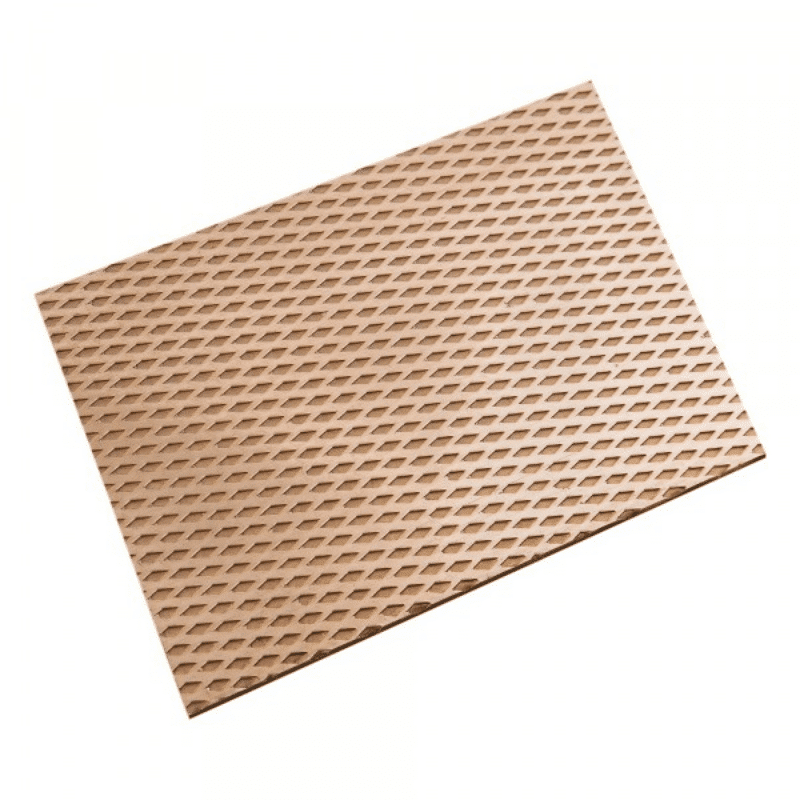

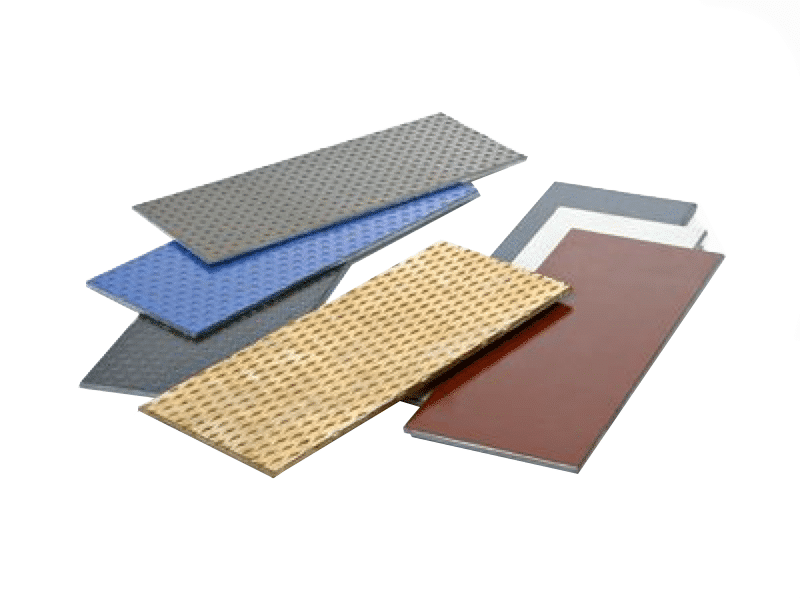

POM Composite Bearing Bushing Strip

Real-life strategy to reach your goals.

POM Lined Plain Bearing (Bushing) – Bearings Bushing Solutions. POM composite strip & sheet, steel backed, metal-polymer bearing material. Providing self-lubricating composite bearings for critical industrial gear drives, leveraging the team’s extensive knowledge base and proprietary brands.

We strive for diversity across the globe

Slide Bearing Composite Bushing Services

Provides a range of slide bearing supply options and repair bearing bushing services, capabilities of design, re-manufacturing, customized, equivalent. Maintenance-Free Operation with Embedded Solid Lubricant pom, Suitable for use in wet and dry applications. Excellent for bushing bearings and sleeve in Hydraulic Pumps and Cylinders. POM composite strips are suitable for applications where a sliding material with self lubricating properties is a prerequisite. Application area examples for pom sliding bushings are:

- agricultural equipment

- construction machinery

- material handling equipment

- home appliances and consumer goods

Metal-polymer composite bushing. POM self-lubricating bushings.

A composite bearing is a bearing made from a combination of materials such as a resin reinforced with fibre and this may also include friction reducing

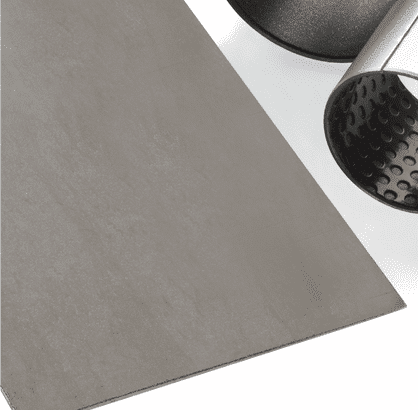

Sliding bearing strip Sheet steel/POM composite Low-maintenance, Low-maintenance

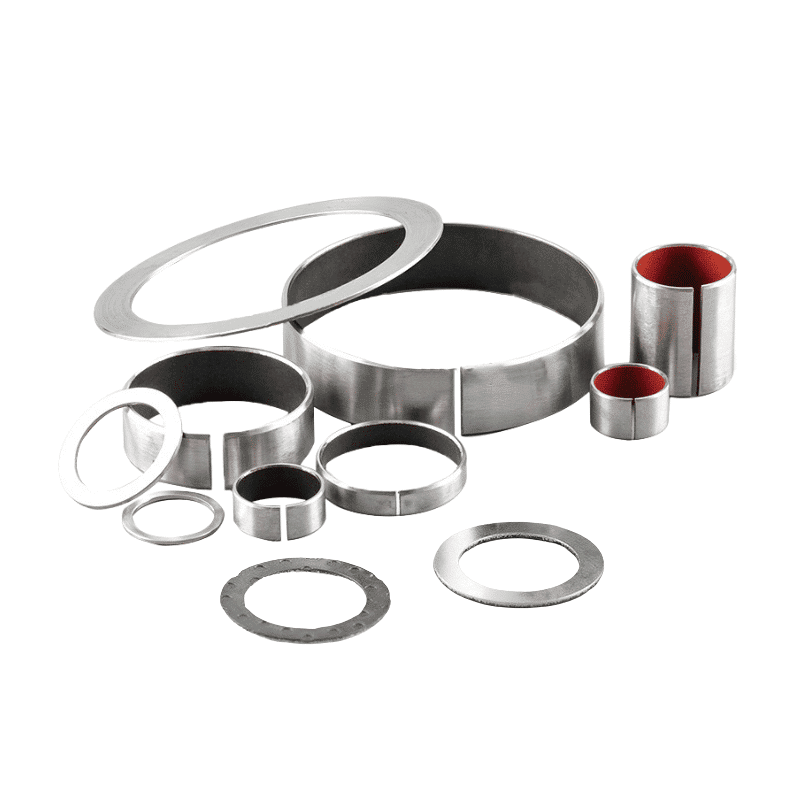

PTFE Bushing Strips

POM Bushing strips

Metal-Polymer Bush

Cusn8 Bronze Sheet Strips

Bearing Bushing Sheet

Composite Bushing Strips

Bearing Sheet

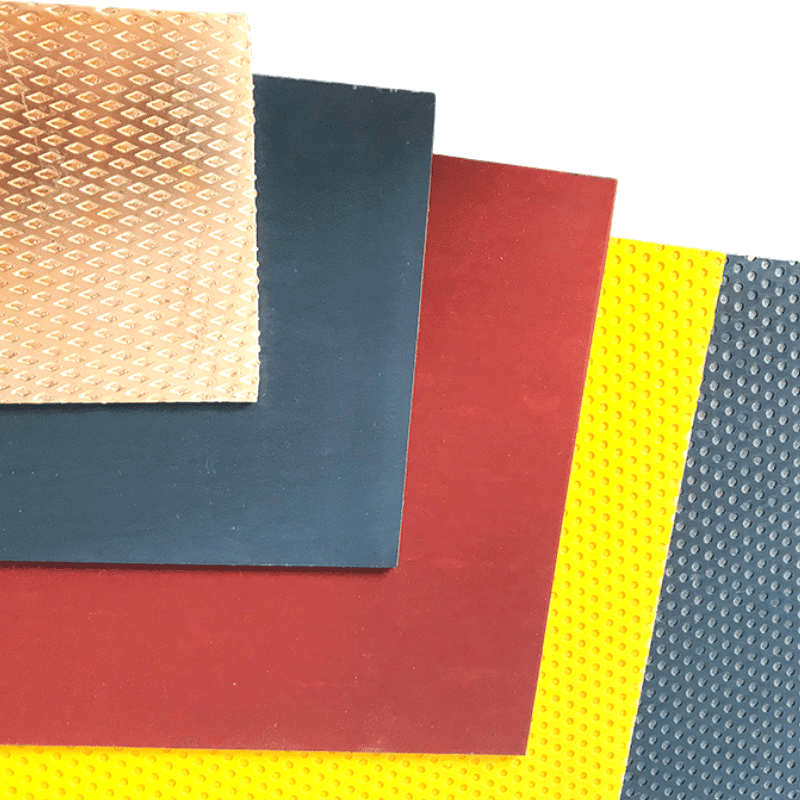

Boundary lubricating composite bearings yellow pom bushes

Bushings, thrust washers and strips. … Made from PTFE and POM composites, for applications with limited axial space, oscillating or rotational movements, Self Lubricating Strips With POM bushing strip. POM composite strips are suitable for space-saving arrangements of all types. These stripes can easily be fit to the application and counterface. They are referred to as pre-lubricated because their material is designed to operate with marginal lubrication.

Advantages of the composite bearings strips include:

- maintenance-free operation

- very good frictional properties

- high load carrying capacity

- high sliding velocity

Metal composite bearing bushing

Real-life strategy to reach your goals.

Sliding bush that reduce friction, wear and power requirements. For heavier-duty requirements in applications requiring a thicker outside diameter edge to provide extended wear life.

We manufacturing pom composite bearing bushing strips tailored to your needs.

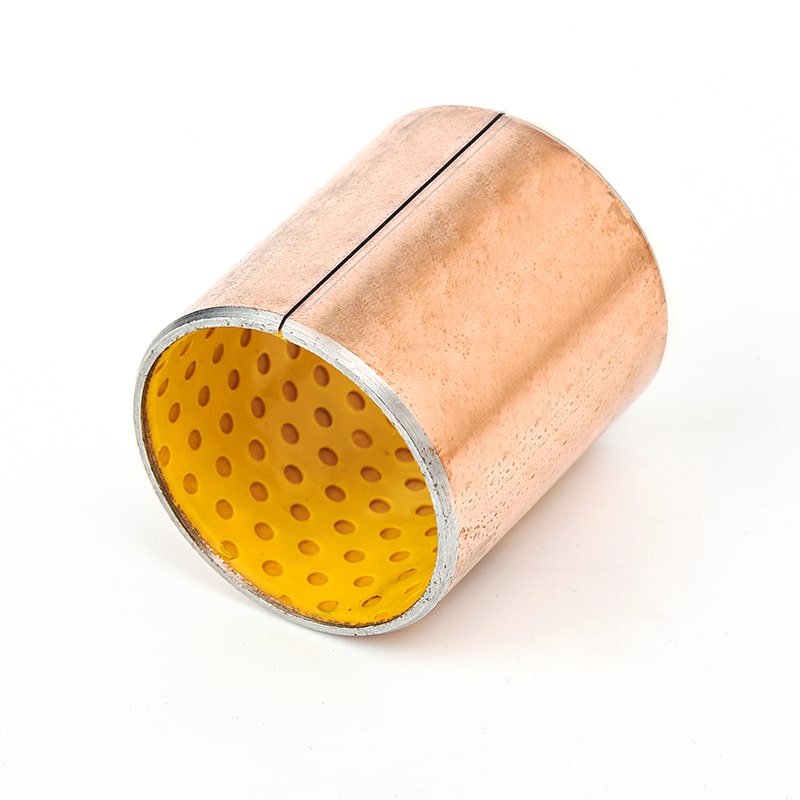

Oil Free Bushing – Multi Layer, Straight, Pom Bushing Features

- Low-Carbon Steel + Porous Bronze + Yellow POM, Intermediate layer

- Sintered bronze [N/mm2]

- Sliding Layer: POM (MoS2)/lubrication pockets

Pre-lubricated composite bearings. Be sure to lubricate during installation.

- Quiet operation with no squeaking or knocking sound.

- Low friction characteristics prevent damage to the shaft (mating surface).

- Composite bearing surfaces remain virtually wear-free with minimal lubrication (grease or oil).

- Very low friction at start-up.

- This allows smooth rotation at start-up and at low speeds under high load conditions.

- Excellent leak-free performance.

- Excellent misalignment tolerance of the shaft.

- Ability to withstand shock loads.

- Excellent load carrying performance even under oscillating and frictional conditions

POM Bushes Strips,Wrapped Dry Sliding Bushings Strips & Material. Metric Size- BronzeLube.com

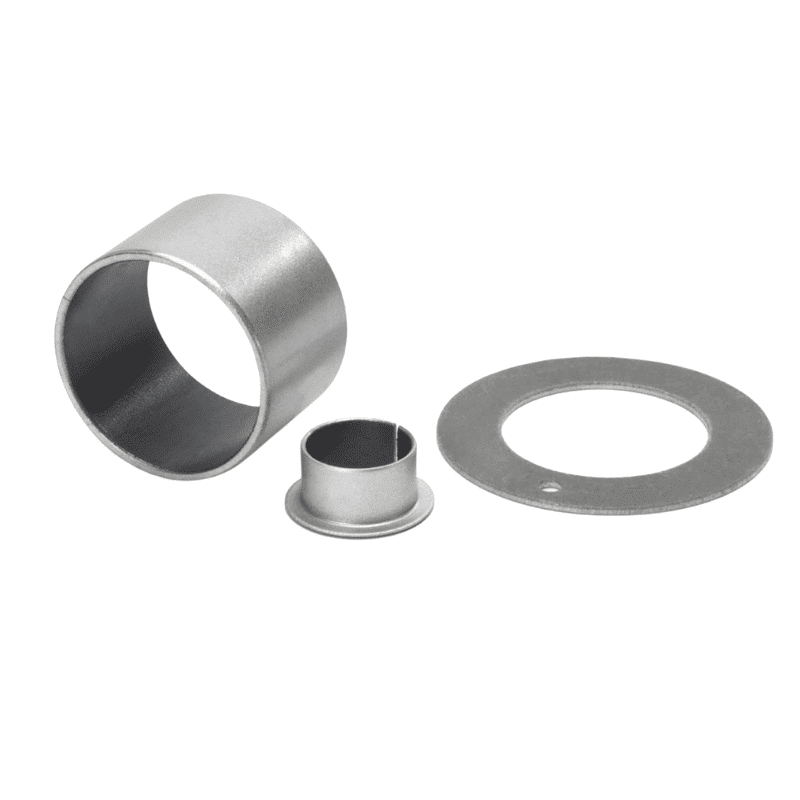

We manufacture ISO 3547/DIN 1494 Steel Backed Composite Bushings.Eco-friendly, lead-free, RoHS-compliant.Tin plating.Series of lubricated composite bearings are widely used in automobile chassis, mining machinery, forging machine, metallurgical machinery and other fields.Especially suitable for lubricating oil can not be continuously or repeatedly supplied occasions.

- Steel Backed Pom Bushings boundary lubricated composite bearing

- Easy to assemble and lubricate, easy to maintain

- High load, good thermal conductivity

- Copper or tin plating on the surface

- Oil groove or oil hole can be designed as required

- Can supply straight sleeve, flanging, gasket and other styles

- DIN 1494 / ISO 3547

POM boundary lubricated lead-free material

POM boundary lubricated lead-free material has the same properties as Composite Ptfe Bushing, and the surface is lead-free. The application field can be expanded to the field with environmental protection requirements.At present, the material has been used in imported textile equipment, plunger pump swing parts, automotive joystick parts and other medium load, medium speed, grease lubrication occasions.

- Maximum bearing pressure: 70N/mm2

- Friction coefficient: 0.05~0.25

- Applicable temperature range: -40℃~130℃

- Maximum sliding speed: 2.5m/s

- Maximum allowable PV value: 22N/mm2.m/s

Composite Bushing Material

The composite boundary lubricated bearing is made of high quality low carbon steel, sintered spherical porous bronze powder in the middle and firmly bound to POM.High quality low carbon steel backed provides high bearing capacity and good heat dissipation performance.The oil pit is filled with grease pressed on the surface, so as to achieve good lubrication between the bearing and the matching shaft.This kind of embellish Sliding bearing has good wear resistance and load capacity.The coating on the steel back surface is corrosion resistant.Because the surface modified polyformaldehyde does not contain lead, the lubrication condition of the bearing is cleaner and environmental friendly.

Thanks to the composite pom material used in plain bearings, they are self-lubricating and maintenance-free, Composite POM Bushes Strips Features

We are involved in the supply of a qualitative range of self-lubricating POM belts to our prestigious customers. The plate offered is designed using the best quality raw material and innovative technology from the supplier in synchronization with industry standards. The plate supplied by us is rigorously tested under the vigilance of our quality experts against various parameters. In addition, this plate can be served by our customers at industry leading prices.

- Rust proof

- Friction coefficient

- Easy maintenance

POM Bushes Strips Technical Data

| Maximum Load and Static Load | 250 N |

| Limit Coefficient of Thermal Expansion | 11 x 10 to 6 K |

| Thermal Conductivity | 4 W/ m k |

| Dynamic Load | 140 N/ mm2 |

| Temperature Limit | 40 deg C to 130 deg C |

| Friction Coefficient | 0.05 to 0.25 |

| Maximum Sliding Speed | 2.5 m/s |

| Wear Depth Limit | 0.50 mm2 |

| Maximum PV Value and Dry Lubricant | 3 N/mm2 m/s |

| Oil Lubricant | 22 N/mm2 m/s |

We strive for diversity across the globe

Self-lubricating Bronze Bush Pom Lined, Volume Discount is available

POM bushes were developed for lubricated applications and consist of three layers: a steel mantle and a sintered bronze layer impregnated and overlaid with polyacetal (POM) bearing material.

Oil Free Bushing – Multi Layer, Straight, Material Structure

- POM with lead 0.3~0.5mm

- Porous bronze 0.2~0.3mm

- Steel backing 0.4~2.2mm

- Copper plating 0.008mm

- The difference is the layer with POM coated.

Huge bushing composite bearing selection

The promise of order pom bushes high quality, meet your requirement. Steel Backed Composite Bearings combine the advantages of conventional metallic plane bearings with the design freedom of self-lubricating.

Straight & Flange POM Bushes – Metric & Inch Size

Standard cylindrical bushings, thrust washers, flanged bushing and strips are available. POM composite bearing material with MoS2 sliding layer and lubrication pockets. An initial greasing during installation is necessary, after that, periodic greasing with oil or grease is mandatory.

A wide variety of composite bearing bushes options are available to you.

Real-life strategy to reach your goals.

Stainless steel composite bearing designed for marine and subsea applications, environmentally friendly in both fresh and salt water, with embedded solid lubricants ptfe or pom for maintenance-free operation! Ptfe composite bush application: Ptfe composite bush are widely used in truck cranes, agriculture machines, hydraulic cylinders, construction machinery, tale gates. As a manufacturer, we produce almost all possible dimensions. Our enterprise, is one of the undisputed supplier of the highly competitive order pom bushes industry in china.

High quality Metal – Polymer Composite Bearing from China

Beautifully crafted leather products.

Wrapped sliding bearing, wrapped bushing, steel/POM sliding layer, DIN 1494/ISO 3547, Low-maintenance, POM bushes are referred to as prelubricated because their material is designed to operate with marginal lubrication.

- Extensive range of composite bushing

- POM Boundary Lubricating

-

Support material: Steel copper-plated or tin-plated

- Intermediate layer: Sintered bronze

- Sliding layer: POM (MoS2)/lubrication pockets